- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pickling of stainless steel

Results for

Pickling of stainless steel - Import export

KASAG SWISS AG

Switzerland

KASAG has many years of experience in staining and passivating stainless steel and aluminium alloys. Our services for single objects are invoiced according to the expense and effort invested, or in the case of larger objects, according to prior quotation. For serial parts, the unit price is taken as the basis for invoicing. Bath pickling: 1,900 x 900 x 800 mm Sprays pickling: 6,000 x 3,000 x 2,500 mm (max. object size)

Request for a quote

ASTRA LT AB

Lithuania

Service for pickling and passivation of welded stainless steel components.

Request for a quoteTRUMER SCHUTZBAUTEN GMBH

Austria

Materials: Normal steel - powder coated RAL 7032 Stainless steel - pickled and passivated (only the product-contacting parts)

Request for a quote

PRAXAS B.V.

Netherlands

The LogTag ST100T-15 external sensor is a strong and safe external sensor specifically designed for use with food. This external sensor is suitable for measuring the core temperature of a product. Place the sensor in the food and measure the temperature accurately.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Milling stainless steel 304 plate

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Milling stainless steel 304 parts

Request for a quote

NOVELTY STEEL

Turkey

Stainless steel is a very common material to use in fabrication projects, thanks to its versatility and durability, among others. Stainless steel possesses high good corrosion resistance which makes it the primary option for industries such as pharmaceuticals, food, petrochemicals and machinery.The versatility of stainless steel requires different fabricating techniques. Stainless steel is a sensitive material which requires delicate weld preparation practices such as thorough surface preparation prior to commencement of welding. Shoddy surface cleaning may compromise the material features such as corrosion resistance. Stainless steel has definite advantages over other metals and, it’s one of the most expensive metal. This high cost puts additional pressure on fabricators to be more careful in fabrication processes. Stainless steel should be fabricated in a specialized clean workshop to prevent contamination. Also it required specialist steel contractors

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC machining stainless steel 304 part

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Turning stainless steel 304 gear part

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Etched stainless steel 304 plate

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Etched stainless steel 304 gasket

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Turning stainless steel pipe

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Turning stainless steel part

Request for a quote

ANDRYS SRL

Italy

One space ground-based bike rack in stainless steel with caps.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

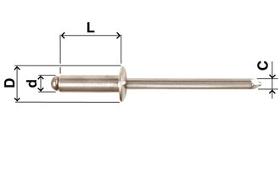

With reference to the Specification: EN ISO 15983 dome head EN ISO 15984 countersunk head 522 525 Materials: Body: Austenitic stainless steel (A2) - Aisi304Cu - X3CrNiCu18-9-4 (EN 1.4567). Nail: Austenitic stainless steel (A2) - Aisi304 - X5CrNi18-10 (EN 1.4301).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GLORI IR KO, UAB

Lithuania

Designation of access panels is to cover plumbing units, electrical units and other types of home installation. They are easily fitting to the walls and ceilings, are durable and reliable. Access panels are made of black or zinc-galvanized metal, also stainless steel. Moreover, we accept individual access panel orders based on special requirements of a customer

Request for a quote

3AS STAINLESS STEEL C.J.S.C.

Turkey

-COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 /430 MEASUREMENT: THICKNESS : 0.40 mm - 6 mm WIDTH: 350 mm - 1600 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO - NARROW COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 /430 MEASUREMENT: THICKNESS : 0.30 mm - 3 mm WIDTH: 210 mm - 900 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO - STRIP COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 / 430 MEASUREMENT: THICKNESS: 0.30 mm – 3 mm WIDTH: 10 mm - 210 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO

Request for a quote

WELMAN METAAL

Netherlands

Online trade stainless steel. We transport all kind off stainless steel arround Europe.

Request for a quote

EDELSTAHL WEIMAR GMBH

Germany

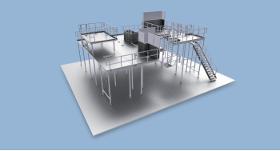

Machine, work and operating platforms from stainless steel for aseptic and hygienic application - for example in the food, beverage, pharmaceutical or chemical industry. We offer the complete package including design and static calculation, manufacturing and assembly. We guarantee stainless steel manufacturing quality made in Germany, quick throughput times and competitive pricing. We are your reliable partner for stainless steel platforms and mezzanines!

Request for a quote

DSM INDUSTRIAL ENGINEERING

United Kingdom

We've been creating worktops for years and with all of that experience comes the ability to develop our processes ensuring that you're getting the perfect product.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quoteResults for

Pickling of stainless steel - Import exportNumber of results

48 ProductsCountries

Company type