- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- parts first

Results for

Parts first - Import export

TECHNOMARK

France

Buddy is a portable dot peen marking machine, controlled by smartphone giving you infinite marking freedom, indoors or outdoors. Its user-friendly mobile application (subject to licence) makes it easy to create marking files. It can be used by an unlimited number of users and with any type of Android 10+ smartphone. It is part of Connect.series, the first range of dot peen marking equipment to offer wireless communication between the marking head and its control unit via a secure WiFi protocol. Buddy has an integrated 22V lithium-ion battery designed specifically to ensure the machine is lightweight, powerful and durable. It's made from hard-wearing technical plastic and features protective bumpers that make Buddy a robust piece of marking equipment. It has a multifunctional support foot for marking on cylinders or at the end of a bar, as well as for holding the head on the parts to be marked.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

IST AG offers ESCC qualified thin-film Pt temperature sensors, applicable from -200 ° C to +200 ° C. The sensors provide stable measuring results at 70,000 cycles from -200 ° C to +200 ° C, which proves that the sensors are resistant against thermal cycles. The temperature coefficient of resistance (TCR) remains very stable, also the sensors proved a high stability regarding drift. Further advantages of the sensors are the small size (L x W x H: 2.3 x 2.0 x 1.1 mm), the light weight and the robustness due to the lack of moving parts. IST AG is the first, and currently also the only supplier providing ESCC qualified Pt temperature sensors. The RTDs are available with different resistances ranging from Pt100 to Pt2000. They are offered with tolerance class B (IEC 60751 F0.3). The temperature sensors are available both as Engineering Model (EM) or as Flight Model (FM). We also offer customization of the sensors, e.g. extended wires (with an ESCC qualified wire).

Request for a quote

ANSMANN AG

Germany

Planning a new development or a redesign of a rechargeable battery or charger? ANSMANN – Your partner from the initial idea through the planning, design, development and manufacturing stages and on to serial manufacturing. Based on your application and the requirements, we can guide you with professional advice for the selection of the correct cells, the capabilities of the necessary protective circuitry, compliance with standards and certification (as early as in the development phase), the first prototypes as STL parts and the first measurements. We can support you through all of the important steps towards your final decision. We can take on the design and manufacturing of the housing parts and the injection and stamping tools required for this. Single-source delivery and manufacturing guarantees optimum interaction between rechargeable battery, BMS and charger. The cells that we use are delivered by renowned manufacturers such as Panasonic, LG, Samsung, Sanyo, A123, Sony, etc.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

ALKIM PETROKIMYA

Turkey

it is a semi-synthetic extra high performance diesel engine oil, which provides excellent lubrication for modern diesel and gasoline engines in heavy-duty conditions and ensures lenger engine life. it meets the latest standards of major American, European and Japanese motor manufacturers.Superior thermal and oxidation stability ensures reduced sludge build-up lenger oil and engine life. High-tech formula protects the engine from corrosion and rust even in high sulfurfuel High level cleaning feature allows the engine to remain clean by controlling piston deposits at an advanced level. Thanks to its excellent fluidity in cold weather conditions, it ensures fast lubrication of engine parts during the first operation and protects the engine against wear

Request for a quote

ALKIM PETROKIMYA

Turkey

it meets the emission standards of exhaust r under the most severe service conditions. it was designed far modern diesel engines equipped with Diesel Particulate Filter (DPF), diesel oxidation catalysts (DOC) and exhaust gas recirculation system (EGR). it is a diesel engine oil with outstanding performance that helps to extend engine life. Superior performance formula increases the efficiency of systems that reduce exhaust gas emissions such as DPF, DOC, EGR, and extend life. Outstanding thermal and oxidation stability prevents deposits at high temperatures and maintains performance during oil change intervals. The new generation of advanced additive technology ensures excellent protection even in heavy duty engines. Excellent fluidity in cold working conditions ensures fast lubrication of engine parts during first operation and protects engine against wear

Request for a quote

ALKIM PETROKIMYA

Turkey

It is a high performance diesel engine oil that provides excellent lubrica tion at high temperatures and extends the life of diesel engines over four seasons. New generation performance features make it unique in low emission diesel engines and older diesel engines that run on low or high sulfur fuels. The active cleaning feature prevents the accumulation of the oil-carbon deposit and extends engine life. it helps to protect against deposits in the cylinder far maximum engine it protects engine from wear by providing rapid lubrication of engine parts during first operation thanks to excellent fluidity in low tempera ture conditions. it reduces oil consumption and reduces maintenance and operating costs by generating a protective film layer that continues even under the most demanding heavy duty conditions

Request for a quote

ALKIM PETROKIMYA

Turkey

it is a fully synthetic motor oil developed to meet the need far extended service life in extreme conditions. it was designed to provide maximum performance from vehicles requiring low viscosity. it provides excellent cleaning power. It maintains performance throughout the oil exchange The new generation detergent dispersants provide maximum protec tion by reducing the engine structure. it helps to reduce oil ageing by providing longer oil change intervals thanks to superior thermal and oxidation stability. Superior protection on engine parts with unique properties in harsh conditions where high temperatures are it protects engine from wear by providing quick lubrication of engine parts during first operation thanks to excellent fluidity in cold weather High oxidation stability minimizes sludge and sludge formation and increases oil change time

Request for a quote

ALKIM PETROKIMYA

Turkey

It is a high performance synthetic engine oil with outstanding perfor mance in the toughest roads and driving conditions. it is an advanced full synthetic motor oil formulated to meet the long-term protection require ments of high-mileage engines. it is alsa suitable far high performance and motor sports applications requiring high viscosity engine oils. It effectively reduces friction and wear due to its durable oil film and more anti-wear additives. High viscosity and outstanding protection at variable driving conditions and temperatures help reducing oil burn. It protects the oil pressure even at high It provides unrivalled protection against sediment and exceptional Thanks to its excellent fluidity in cold weather conditions, it ensures fast lubrication of engine parts during the first operation and protects the engine against wear. Outstanding protection against wear and corrosion under high perfor mance and racing conditions It maximizes short and long-term motor

Request for a quote

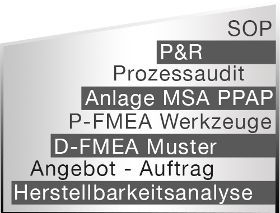

MECHASYS GMBH

Germany

In terms of project management, the respective feasibility study is a matter of course. No offer without a feasibility study. -An offer implies manufacturability; this is how our process is defined! - We live from prototypes and small series. Often there is no second assignment, so there shouldn't be any unforeseen surprises. Or at least only within a manageable framework. The combination of metal and plastic composite parts makes this a challenge from time to time. But you can be sure that here we draw on a wealth of experience that we would like to share with you.

Request for a quote

LVD

Belgium

The ToolCell makes any bending application easier and more productive using revolutionary bending automation technology that minimizes setups, is fast and highly reliable. An integrated automated tool changing system stores a library of top and bottom tooling. All tools are held within the machine and automatically changed as the job requires – significantly minimizing tool changeover time for better bending productivity. LVD’s patented Easy-Form® Laser in-process angle monitoring and correction technology ensures the first part is a good part. KEY FEATURES TOUCH-B touch screen graphical user interface control is intuitive and simple to use All tools held within the footprint of the machine Large library of tools: 2 complete lengths of self-seating top tooling (punches) and 5 complete lengths of bottom tooling (Vee dies) Flexible tooling configuration Automated tool loading and unloading Equipped with Easy-Form Laser Precise set-up for every job – No fine adjustment of tool stations

Request for a quote

CUPERNICAN

Lithuania

We have three parts to complete our sign off process. All parts must be completed in order to go any further with the process. 1. The first part is the artwork acknowledgement form. 2. The second part is to sign the final artwork template when you are happy with this. Then simply scan this back in and send to us. 3. The final part, you may also need to pay a deposit fee in order for manufacture to begin. There is also the option to have us hold stock for you for a set period of time. This agreement will be available on request, just talk to your representative to see if this is an option for you.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 60-LT" is a powerful robot press automation with an outstanding storage system for the highest demands in the handling of pressed parts made of hard metal and metal powder. With a storage capacity of up to 60 sintering plates, the it offers outstanding possibilities for the production of sintered parts of all types. All sintering plates are fed to the machine via four transport trolleys with 15 plates each. The intelligent handling system of the "RPA 60-LT" ensures uninterrupted loading of the pressed parts. While the first sintering plate is filled by a linear robot with multifunctional gripper, the handling system provides a second empty plate. As soon as the first plate is filled, the loading of the second one starts. Meanwhile, the handling system returns the loaded sintering plate to the transport carriage. The automation thus works according to the Kanban principle, which ensures that the press can be operated continuously even during the workpiece carrier change

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARLIM SPRITZGUSS GMBH

Austria

Test tool First serial parts within a short span of time. By producing a test tool it is possible to offer our customers LSR injection molding parts which after a brief time span were made under mass production conditions. We offer Injection molding of mass production-like LSR parts Maximum output 2,000 items Delivery times between 6 and 12 weeks after clearance of order form by the customer Any type of material, color and surface finish available Parts may be post cured You get not only prototypes but genuine serial parts to subject to your own tests. SHARE:

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Rapid Tooling Early mass production-like LSR parts within only 10 working days – this is rapid tooling starlim//sterner-style. Rapid Tooling – fast tool making – was developed so our customers could be offered first LSR injection parts after a brief time span; those parts were made under mass production-like conditions. We offer Injection molding of mass production-like LSR parts Maximum output: 300 items Dimensional tolerances in accordance with DIN ISO 3302-1 M1 Standard surface quality max. VDI3400–24 (</= Ra 1.6) Choose between 10-20 working days delivery time after clearance of order form by the customer Limited choice of "standard" materials and colors Parts can be post cured Engravings, data codes and tolerances/surface finish deviating from the standard are not possible Your advantage You have to wait for a maximum of 20 working days until you receive your first serial parts. You have price control because delivery time determines the price. If you need it really quickly, the

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Multi-Program Memory: Simply press the program number required to restore all your settings. 5 and 10 program versions are available. Fitted to all Priorclaves Automatic Freesteaming gives a venting period during heating, which greatly improving temperature distribution and air removal. Also available – Pulsed Freesteaming – for improved waste load performance. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. 2-Year Warranty Package: with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Waste Containers: for operator safety and protection of your autoclave with waste loads. These contain spillages whilst allowing good steam penetration. Stainless Steel Wire Baskets are also available. ****** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Multi-Program Memory: Simply press the program number required to restore all your settings. 5 and 10 program versions are available. Fitted to all Priorclaves Automatic Freesteaming gives a venting period during heating, which greatly improving temperature distribution and air removal. Also available – Pulsed Freesteaming – for improved waste load performance. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Multi-Program Memory: Simply press the program number required to restore all your settings. 5 and 10 program versions are available. Fitted to all Priorclaves Automatic Freesteaming gives a venting period during heating, which greatly improving temperature distribution and air removal. Also available – Pulsed Freesteaming – for improved waste load performance. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. 2-Year Warranty Package: Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Waste Containers: for operator safety and protection of your autoclave with waste loads. These contain spillages whilst allowing good steam penetration. Stainless Steel Wire Baskets are also available. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Multi-Program Memory: Simply press the program number required to restore all your settings. 5 and 10 program versions are available. Fitted to all Priorclaves Automatic Freesteaming gives a venting period during heating, which greatly improving temperature distribution and air removal. Also available – Pulsed Freesteaming – for improved waste load performance. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Fitted to all Priorclaves Media Warming keeps sterilised media ‘ready to pour’ at the end of the cycle. An end to early morning starts to melt media! 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Multi-Program Memory: Simply press the program number required to restore all your settings. 5 and 10 program versions are available. Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Fitted to all Priorclaves Fan Cooling blows cold air over the autoclave vessel reducing cooling times to safe load temperatures. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. (UK Customers Only) ***** ASK FOR A QUOTE *****

Request for a quote

ABES S.À R.L. PUBLIC DESIGN

Luxembourg

ABES Waste-Container 523 is a stand-alone waste container. The first part of consists of a frame made from two parallel tubes, connected by a lower and an upper rim as well as a cover, the second part consists of a cylindrical steel container to be hung into the frame. The container can be swung off the frame. The container is attached to the ground from the inside. Contents approx. 50 l. Mounting On the ground from the interior of the container base. Finish – Powder coating in standard RAL colours or DB 703. – Other colours or multicoloured configurations are available on request at a surcharge. – Incl. internal container or alternatively with spikes to hold bin liners. – Cover including ashtray (500.001) available as an optional accessory. – May be unlocked for emptying using a triangular key. Order Information Art. N° 523.002

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Multi-Program Memory: Simply press the program number required to restore all your settings. 5 and 10 program versions are available. Vacuum Options: A powerful vacuum pump draws a series of evacuations to ensure air removal from difficult loads. Vacuum drying is also available on all models. Loading Trolleys and Loading Cassettes are available for all front loading, RSC and Power Door Models. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. (UK Customers Only) ***** ASK FOR A QUOTE *****

Request for a quoteResults for

Parts first - Import exportNumber of results

46 ProductsCountries

Company type

Category

- Autoclaves (23)

- Import-export - oil (5)

- Welding work - steels and metal (5)

- Brakes, servo-brakes and accessories (1)

- Cutting - machine tools (1)

- Dustbins, waste bins (1)

- Hoists and elevators, construction (1)

- Management training (1)

- Marking machines (1)

- Mechanical engineering - custom work (1)

- Paper - raw materials (1)

- Sensors (1)

- Washing systems for the food industry (1)