- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pallet conveyor systems

Results for

Pallet conveyor systems - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Pallet based automated car parking system RESPACE Pallet based technology The pallet based automated car parking system RESPACE is an interesting solution for creating up to 50 parking spaces. Drivers park their car on a pallet in a cabin. The cabin is the only interface between the driver and the car park. From this point everything is automatic. The door of the cabin closes and the car is transported downwards by lift. From there the car standing on the pallet is brought to a free parking space via roller conveyors. The pallet based parking system RESPACE is characterized by a very compact design. From the lift the pallets with the vehicles are moved directly to adjacent parking spaces. Car parking and removal follows according the puzzle principle. The car park has 60 parking spaces and is used as a hotel car parking, but also available to the public.

Request for a quote

FERPLAST SNC

Italy

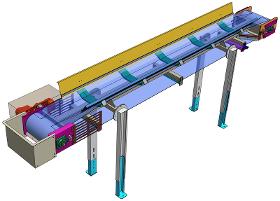

MOTORIZED ROLLER DIAMETER MM. 60 PITCH MM. 80 FOR HANDLING PALLETS We realize motorized rollers conveyors with diameter mm. 60 and pitch mm. 80. They consist of a sturdy frame in painted steel and supports with fixable feet, adjustable height. The high-quality rollers are made of galvanized steel with rotation on shielded ball bearings and complete with pinions or sprockets. The transmission is a chain loops or tangential chain. The geared motors groups have suitable power with start/stop switches or photocells control. Normally the rollers have an useful width of mm. 800-1000-1200-1500 and module length of modules mm. 2000-3000. Ideal solution when handling pallets, containers with reduced base and standard pallets with cross feed.

Request for a quote

FERPLAST SNC

Italy

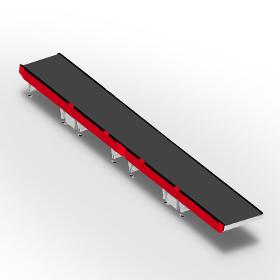

FREE ROLLER CONVEYORS DIAMETER MM. 60 AND PITCH MM. 80 FOR PALLETS The free roller conveyors P80 are characterized by a rollers diameter of mm. 60 mm and pitch mm. 80 and are the ideal solution when handling pallets, containers with reduced base and standard pallets with cross feed. They consist of a robust structure coated steel profile, with fixable supports and adjustable feet. The rollers are of high quality made of galvanized steel. Rotation on shielded ball bearings with permanent lubrication. The roller conveyors are built according to the scale, size and characteristics of packages to be handled.

Request for a quote

ORBIS EUROPE

Germany

Durability, cleanliness, product protection – plastic pallets for food and beverage applications need to meet high standards and requirements. ORBIS Europe plastic pallets are designed to convey aluminum and steel cans, glass and plastic bottles, can ends and other rigid packages on many palletizers and conveyor systems. - Compatible with existing supply chains in different geographies - Easy to clean all-plastic design - Reusable with a long service life - Tapered 4-way entry - Options available (e.g. hot stamp, grommets) We offer a variety of footprints and designs that fit into existing processes and systems: 1180 x 1265 1120 x 1300 1120 x 1420 1000 x 1200 From Wood to Plastic for the Environment Switching from wooden pallets to plastic pallets improves workplace safety and cleanliness in your operations. ORBIS plastic pallets are durable and make a tremendous number of trips before being recycled.

Request for a quote

TRAPO GMBH

Germany

With decades of know-how and worldwide expertise in the core areas of conveyor technology, robot systems, palletizing, depalletizing and automation, TRAPO AG presents itself as a renowned manufacturer and total systems supplier of conveyor systems, palletizing technology and packaging machines. Primary and secondary packaging such as cartons, trays, pails and more are palletized and depalletized. The machines in our systems impress with their flexibility, high performance and economic efficiency. We produce in Germany and set standards worldwide ranging from engineering contracts to automation. The palletizers of the HLP series operate with high and low inlet. The product range of the high-capacity layer palletizers is optionally equipped with a y-axis, rotary module or even a traversing axis — so that one or more palletizing stations can be operated as required.

Request for a quote

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

NOVOSIM

Turkey

A Pallet Stacking Machine/ Pallet Rack Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, a

Request for a quote

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The DAMBACH material flow system (MFS) enables easy connection of automated storage and retrieval systems as well as conveyor systems to ERP and warehouse management systems (WMS). The software package named MFS-BASIC is distinguished by the variable transport control of storage and retrieval machines, pallet-shuttle-systems, conveyor technology and rail guided vehicle systems. Flexible route strategies enable utilization-dependent regulation of material flows. Whether management of top performance in large floor conveyor systems with switches or optimized buffer space management in conveyor technology systems. The powerful MFS from DAMBACH fulfills many requirements. Depending on the functional scope of the customer's warehouse management system (WMS), DAMBACH offers the option of an expanded material flow system named the MFS-PLUS.

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Gentle transport of products and high performance due to continuous chain run • Intermediate buffering of several products possible • Up and down movement with same side or opposite side infeed/outfeed Vertical lifts make material flow across several levels possible and are used wherever goods need to be transported vertically - they are ideal for the vertical transport of boxes, trays, plastic containers, bundles, pallets, and bags within automatic conveyor systems. Vertical Lift SPF1S: Transport direction in “S” form. Outfeed side always opposite the infeed side. Vertical Lift SPF1C: Transport direction in “C” form. Outfeed side always on the infeed side.

FEMIA INDUSTRIE

France

Provides receiving, storage and feeding of the product downstream. The dimensions can be adapted according to the capacity of the line and the means of unloading raw materials used. A conveyor belt with high sides which provides the storage and transport of products.

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

Installed at the line infeed of granular products such as peas/flageolet beans, it extracts small size waste and sticky waste as well as large waste. Machine primarily comprised of a drum of which the perforations of the final section are adapted to the product processed. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Products to be processed exit from the 3rd section of the drum. Collection and discharge of waste thanks to a conveyor inside the drum (except for small size waste at the beginning of the machine).

Request for a quote

GSW SCHWABE AG

Germany

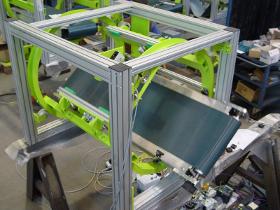

with its compact design using a structural aluminum profile, conveyor system is ideally suited for continuous duty applications in multiple shift environments. using the benefits of modular construction, this conveyor can be readily integrated into new or existing equipment or be used as a freestanding conveyor for bulk handling and loading aplpications. inclination smoothly adjustable steplessly fourwheel drive, 2 steering wheels with parking brake 13 collector rollers, height 20 mm transport cover PUeven, 2 layers, to be used at temperatures from 30 120°C, oiland grease resistant, antistatic funnel (attachment), aluminium anodized drop area pivotable clip/aluminiumclosed bar system suitable for materials to be conveyed from a thickness of 2 mm on for lower thicknesses of materials to be conveyed, allaround corrugated material edges made from celloflex. This reduces the usable width of the material by approx. 70 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HO-MA GMBH

Germany

Its flexible design makes the flush-grid belt conveyor particularly compact and its curve radius can be adjusted.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt offers a range of straight conveyors designed to ensure efficient operation, improved belt life and maximum cleaning ability. Our straight conveyors feature an open construction with the belt being supported on food grade high density blue polyethylene wear strips clipped to the stainless steel framework. All of our conveyors are suitable for use in hygiene-sensitive environments common to the food and pharmaceutical industries.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

The necessity to spread/separate or converge products while they are moving on a process belt conveyor is a major requirement for a wide range of food, confectionery and industrial applications. In many cases this allows processors to run narrower conveyors saving factory floor space. Coating processes also benefit by separating product and reducing rejection rates.

Request for a quote

OMS MEKANIK OTOMASYON SISTEMLERI SANAYI TICARET LIMITED SIRKETI

Turkey

Conveyor can be manufactured in desired dimensions and dimensions. Conveyor provides simple transportation of products to be transported or shipped from one place to another. We produce conveyors according to the type, weight and quantity of the products It works with the motor system and the speed can be adjusted. Conveyor belt selection is made according to the characteristics of the products. Systems 7-8 bar air system is required. Made of polycarbonate plastic food and chemical resistant or cloth resistant non-slip pad. Products can be manufactured from 316-304 or painted sheet products depending on the situation

Request for a quote

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

IDDLER ROLLER CONVEYOR Standard Widths 300 mm, 450 mm, 600 mm, 800 mm, 1000 mm Standard Drum Dia Ø 51 mm Steel & Ø 50 mm Aluminium Standard Lengths 1000 mm - 6000 mm Upon Request Lengths 6000 mm - 60000 mm

Request for a quote

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

MINIATURE CONVEYOR Standard Widths Ø 20 : 20 mm, 40 mm, 80 mm, 150 mm, 200 mm Ø 30 : 30 mm, 60 mm, 90 mm, 120 mm Ø 35 : 120 mm, 150 mm Ø 45 : 45 mm, 90 mm, 135 mm, 180 mm, 200 mm, 300 mm, 450 mm Standard Drum Dia Ø 20 mm & Ø 30 mm & Ø 35 mm & Ø 45 mm Standard Lengths Optional.

Request for a quote

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

ASETAL BELT CONVEYOR Standard Widths 82,6 mm, 114,5 mm Standard Gear Dia Ø 109 mm Standard Lengths 1000 mm - 6000 mm Upon Request Lengths Optional.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

An innovative new design to allow you to easily sort packages and parcels during your manual sortation process. The unit can also be supplied with an integrated weight scale unit with a digital display. Adjustable Height Telescopic leg sections to raise or lower the conveyor bed height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement. Castor brakes lock both wheels and swivel simultaneously while the conveyor is in use.

Request for a quoteResults for

Pallet conveyor systems - Import exportNumber of results

64 ProductsCountries

Company type

Category

- Conveyor systems (46)

- Conveyor belts (8)

- Storage equipment and systems (4)

- Palletising machinery (2)

- Bottling and filling - machinery and equipment (1)

- Grids, gratings and wire mesh (1)

- Machine tools, metal shaping - parts and accessories (1)

- Pallets (1)

- Parking lots - equipment (1)

- Plastics - machines and material for industry (1)

- Racks and bins (1)

- Warehouse logistics (1)