- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packer

Results for

Packer - Import export

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

FERPLAST SNC

Italy

The MINIMA packaging machine designed for medium/small production realities (artisanal, commercial, etc.), makes versatility and minimum bulk its strengths. Absolute reliability and high efficiency, combined with high operating silence, low energy consumption and ease of use, unique in its kind, are qualities that make it a cutting-edge product. All the functions of the machine are displayed and controlled electronically thanks to the digital panel. The dimensions of the support surface are 350x240x140 mm h (height of the closed hood) The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product. The choice of the machine must take into account that: the front opening of the "Minima" bell is 23 cm but laterally drops down to zero the dimensions of the box (height + depth) must not exceed the width of the reel 350 mm also considering that there must always be at least 50 mm of waste.

Request for a quote

FERPLAST SNC

Italy

FC LINE HOOD PACKAGING MACHINE The FC LINE has a fresh design and solid structure, an electronic of new generation, and several other technical improvements which improve even more the performances of these machines. Three models are available with a support plan of mm. 400x250x200h - mm. 520x390x250h - mm. 580x780x250h. The dimensions of the support surface are to be considered with the closed hood. The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

Bag filling with the BEHN + BATES impeller packer is achieving best filling results due to low-air filling and high filling pressure

Request for a quote

FERPLAST SNC

Italy

New packaging machine with transparent bell RP series with solid steel structure, the latest generation of electronic, front control interface, intuitive programming, more space in the packaging space and a whole host of technical features that enhance performance yet. Three models are available with a support surface of mm. 400x250x200h - mm. 520x390x250h - mm. 580x780x250h. The dimensions of the support surface are to be considered with the hood closed. The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product.

Request for a quote

FERPLAST SNC

Italy

HOOD PACKAGING MACHINES - FP 5540 – FP 7060 SERIES L-seal hood shrink packaging machine combines sealing with shrinking into one step. The operator places the product between the two layers of mono-fold film, then moves the package into the sealing area and lowers the hood. When the shrink time is completed, the hood is returned to the up position and the operator may remove the completed package . The transparent cover makes the process of sealing & cutting and shrinking be visible. Colours: dark gray or orange depending on availability. It suitable for PVC shrink films with max. thickness 30 my and POF shrink films with max. thickness 19 my. Two models are available with a support surface of mm. 500x400x250h - mm. 650x550x300h. The dimensions of the support surface are to be considered with the hood closed. The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product.

Request for a quote

LANTECH

Netherlands

Profit Pack Machine Bypass Mode This option allows the Profit Pack product conveyor to continue to run, while bypassing the Sealer. Access through HMI. Profit Pack Complete Detection Beacons This option provides a complete detection four color LED beacon on the Erector that alerts operator. Top to bottom; Red burning - general failure, Orange blinking - low tape, Orange burning - out of tape or broken tape, Blue blinking - low blanks in magazine, Blue burning - magazine empty, Green burning - machine in standby. Detection on the Sealer; Orange blinking - low tape, Orange burning - out of tape or broken tape, Green burning - machine running or standby. Profit Pack Product Conveyor Height Adjustment Hydraulic height adjustment on Profit Pack product infeed conveyor between 39.36" - 47.25" (1000-1200mm). Infeed Product Conveyor Width 7.87" (200mm) Smooth Surface Belt Standard smooth surface belt with width of 7.87" (200mm). Infeed Product Conveyor Width 13.77" (350mm) Smooth Surface...

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

The vertical vacuum packing machine is a specialized equipment used in packaging that removes air from a package or container, creating a vacuum environment. This equipment is commonly used across industries for preserving and extending the shelf life of perishable goods, protecting items from moisture and oxygen exposure, and maintaining product freshness.

Request for a quote

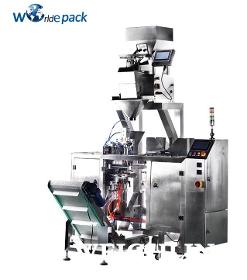

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The product is suitable for fast and efficient packaging of chilled fresh meat, cooked meat products, cheese, soy products, aquatic products, poultry meat, etc. It has the characteristics of keeping food quality, fresh and shape. Packaging advantages:Improve the appearance value, strong three-dimensional effect, transparent and beautiful, easy to touch and inspect, and neat and beautiful.The product is fastened to the pallet, which can be shockproof, anti-friction, and anti-scratch; and vacuum-sealed, which can prevent moisture and oxidation, protect the quality of the product and prolong the shelf life.Compared with traditional packaging, its appearance display and shock protection effect are greatly improved, which enhances market advantages, expands sales opportunities, creates real value, and enhances brand influence.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with liquid pump cylinder measurement,accurate measurement, fast speed, low defective rate, low noise,add the reflow system can avoid liquid material leakage. 2. Eight stations rotary design to automatic control of a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5.Modular heating, more accurate temperature control, heating failure can alarm prompt. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with servo auger/agitator feeder system,30-50L fillers,and lifting conveyor,accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design ,compact and reasonable arranged in the smallest amount of space,to automatic control of a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.Adopt Siemens PLC control system, touch screen can set variety of languages,simple operation, and easy maintenance. 4.The machine use premade pouch,you have more choice for the bag type and excellent appearance .Sealing good, the finished product looks high-end. 5.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 6.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary pouch bagging vacuum packaging machine combine with different fillers,such as weighing machine,liquid pump and auger/agitator fillers, accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling,vacuuming,sealing,and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials.Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids. 3.Adopt Siemens PLC control system, be easily performed operation and maintenance. 4.Filling machine rotates intermittently to fill the product easily and vacuum machine rotates continuously to enable smooth running, it means high performance and high durability.All grippers width of filling machine can be adjusted at once by a motor but all grippers in the vacuum chambers are no need to adjust.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. Rotary packing machine combinate with the multi-heads weighing machine, Z-type conveyor, platform, accurate measurement, fast speed, low defective rate, low noise. 2. Eight stations rotary design to automatic control a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5. The lifting system is suitable for a wide range of industries, like food fodder, chemical, and so on granule material packing. 6. Strictly follow the mechanical standards to production, ensure the quality, reduce late wear, and reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.The machine use premade pouch,you have more choice for the bag type and excellent appearance . 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.The main configuration is Siemens PLC control system,simple operation, and easy maintenance. 4.The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch. 5.Easy to link up with other packaging equipment such as multi-heads weigher, liquid pump filler, auger/agitator fillers, feeding conveyor,platform,the cartoning machine,case sealer etc. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Equipped high-quality performance various weight filler and mini doypack machine with auto ziplock opener and output conveyor, date printer as an option for solid granules, powder, liquid, paste, etc. Apply for different premade pouch types, such as Custom Packaging Styles flat Bottomed Pouch, Stand Up Pouch, Quad Seal Bag, Flat Pouch – 3 Side Seal Bag, Shaped Pouch, Retort Pouch, Kraft Paper Bags. Bulk material feeding conveyor as an option available Various weight fillers such as auger filler, multi-head, linear, pump filler, etc. Supporting stand Mini Doypack Machine Output conveyor Metal detector and weight checker as option

WINTERHOFF PICARD GMBH

Germany

Your foil and processing requirements determine our knife design. Regardless of whether the foil should be impermeable or permeable, vacuumable or sealable, tearable or much more, they will be cut reliably with the best possible knife.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PETAINER

United Kingdom

Petainer PET wide-mouth Jars are ideal for powdered products that require a scoop. Available in different shapes, sizes and colours, they increase your on-shelf presence and brand awareness. PET Jars are lighter than HDPE and glass alternatives, reducing your carbon footprint. They are easy to transport and deliver excellent top-load performance with an in-built stackable base design. Our jars have a smooth neck finish and are perfect for induction heat seal. They have a dedicated label area for branding opportunities and on the round shape it is recessed for added protection. Petainer wide-mouth jars can be supplied with handled or non-handled closures with the possibility of engraving the company logo. Petainer jars are strong and unbreakable. They have excellent impact resistance, which allows the safe transportation of consumables. PET will keep your product in perfect condition with barriers against moisture, UV and Light, maximising shelf life. Our wide-mouth jars are BPA free.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

FAST AND PRECISE – FOAMplus® HAND PACKER FOAMplus® Hand Packer is the ideal solution for special challenges, including those posed by bulky and heavy packaged goods as well as products with complex contours. The handy foam gun allows you to accurately fill the carton with foam packaging in mere seconds – for customized blocking and bracing and the perfect transport of packaged goods. Foam pre-molded cushions can also be conveniently formed in advance with FOAMplus® Hand Packer. The microprocessor-controlled foam packaging system is extremely efficient, requires minimal maintenance thanks to the self-cleaning mixing chamber, and ensures seamless, cost-effective foam production in consistently high quality.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

POWERFUL AND INDIVIDUAL – FOAMplus® BAG PACKER² The FOAMplus® Bag Packer² system produces foam packaging bags at the touch of a button, which adapt specifically to the contours of the packaged goods. Thanks to the proven foam-in-bag system, film bags can be filled with foam automatically through regular batch production or individually, directly at the packing station. When a bag is produced the expanding polyurethane foam pad will quickly mould itself around any product shape in seconds, and affords the highest degree of protection against shock, vibration and compaction. A robust solution for goods in transit and storage that ensures products arrive in perfect condition. Thanks to its low weight, it also reduces transport costs. FOAMplus® Bag Packer² features a user-friendly display screen, where you can adjust the size and fill volume of the bag, program bag sequences, and store defined packaging sizes in the system. The FOAMplus® Bag Packer² is designed to run four film...

Request for a quote

JK FRANCIS AND SON LTD

United Kingdom

Our Export Packing services provide the very best protection available for your goods, With over 105 years of trading and experience behind us were one of the UK's leading suppliers of Export Packing services. Our team of experts will advise the most appropriate protection required for transit or we can work to any given packing specification. Were the first choice for protecting your goods during transit. https://jkfrancis.com/export-packing/

Request for a quote

SPF SWEDA LTD

Ukraine

The Big-Bag packing machine SWEDA DWS-301-1000-1 is intended for batching bulk materials into super sacks (“Big-Bag”). The Big-Bag filling machine can be used for batching cereals, sugar, compound feed, mineral fertilizers, granules and other bulk materials. Features: -High capacity (15 bags per hour); -Stainless steel tract (optional); -Fan for blowing the bag eliminates spillage of the product; -Protection of the weighing platform from being hit by a loader; -Communication with the automated control system of the enterprise and the owner’s office; -There are no special requirements for operating conditions and staff; -Prompt mounting, adjusting and put into operation. More details about our weighing and packing equipment you can find on our site: www.sweda.com.ua/en We are in social networks: Facebook: https://www.facebook.com/SPFSwedaLtd Instagram: https://www.instagram.com/easyweighing/

Request for a quote

TANOS GMBH

Germany

A big choice for small loads. With the new and practical height of the MINI-systainer® T-Loc III, you have even more options for storing products in a space-saving manner. New features of the MINI-systainer® T-Loc III include fully-functional card compartments, with label sets available as accessories. Of course, the MINI-systainer® T-Loc III can be attached to the MINI-systainer® T-Loc I as usual. * The exterior dimensions, measured without the feet, are: H + 4.7 mm Outside dimensions H* 142 x W 265 x D 171 mm Inside dimensions H 124 x W 254.5 x D 154.5 mm Weight: 0.60 kg * The outside dimensions are measured without feet: H + 4.7 mm

Request for a quoteResults for

Packer - Import exportNumber of results

29 ProductsCompany type

Category

- Packing and packaging - machinery and equipment (11)

- Bottles and jars, plastic (6)

- Bag filling machinery and equipment (3)

- Knives, industrial (2)

- Packers - companies (1)

- Custom packaging (1)

- Custom packaging - companies (1)

- Food Industry - Machines & Equipment (1)

- Food industry packaging machinery (1)

- Tools & Hardware (1)