- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pack wrapping machines

Results for

Pack wrapping machines - Import export

FERPLAST SNC

Italy

Semi-automatic wrapping machine mod. FP BOX with rotating table, suitable for wrapping boxes and small packages. The rotation of the table is motorized, activated by the pedal and with adjustable speed; the movement of ascent / descent coil is manual with reel holder counterweighted. The standard table has the turntable completely smooth. You can request the non-slip rubber coating or different locking systems of the pack. Current promotion: The FPBOX wrapping machine for boxes is supplied with a free inverter that allows the adjustment of the rotation speed of the rotary table from 10 to 20 rpm

Request for a quote

POLIBAG AMBALAJ KIMYA SAN.TIC.ŞTI.

Turkey

stretch wrap food stretch food

Request for a quote

POLIBAG AMBALAJ KIMYA SAN.TIC.ŞTI.

Turkey

stretch food food stretch

Request for a quote

POLIBAG AMBALAJ KIMYA SAN.TIC.ŞTI.

Turkey

30 cm and 45 cm food stretch roll 9 my , 10 my , 11 my

Request for a quote

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO/A ROLL for wrapping carriages (roll container), with manual hooking/cutting of the film and automatic wrapping cycle, limit switches adjustable in height to stop reel holder, adjustable limit switches at the base of the reel holder to start wrapping to the desired height, touch panel display with 3 programs winding, truck driving, foot operated mechanical lock, loading ramp for pallet trucks. (Machine CE).

Request for a quote

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO ROLL for wrapping carriages (roll container), with hooking / manual cutting of the film and buttons for ascent/descent of the reel, guide carriages, foot operated mechanical lock, loading ramp for pallet trucks, progressive starting device. (Machine CE).

Request for a quote

FERPLAST SNC

Italy

FP 15 SE STRETCH-WRAPPING MACHINE with electronic board and digital keyboard, inverter to control the progressive start and turntable rotation speed, 4 wrapping programs, electromagnetic clutch for film tension control, photocell for automatic reading of the pallet height, manual hook up/cutting of the film, and automatic wrapping cycle (CE-standard).

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform, attach the film to the base, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. On requrest we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic balance with load cells Load/ Unload rollers STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product

Request for a quote

FERPLAST SNC

Italy

Wrapping machine semi-automatic with turntable mod. FP BOX - TIRES, suitable to the winding of tires coupled with internal diameters from 300 mm to 500 mm. The rotation of the table is motorized, activated by the pedal and with adjustable speed; the movement of ascent / descent coil is manual with reel holder counterweighted. The machine is equipped with the compressed air device by drive via lever valve for centering and locking of the wheels, consisting of two jaws which are installed on the expansion of extractable pins. To lock and unlock the tires is sufficient to drive the valve lever. The group expansion is raised by about 150 mm. from the plane table.

Request for a quote

FERPLAST SNC

Italy

Wrapping Machine Mod. FP 15 SE/T with table cut for loading and unloading with pallet, and safety photocell, photocell height sensing pallet, digital panel with 3 programs winding, inverter for soft start, manual lock/cut of the film and automatic wrapping cycle (machine CE). NOTE: the machine is loaded from the side. When ordering, with a surcharge, it is possible to obtain the modification for the front load. UPON REQUEST WE CAN MAKE WITH WRAPPING MACHINES: Rotary table diameter mm. 1800 (pallets up to 1300x1300 mm)Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product.

Request for a quote

FERPLAST SNC

Italy

New packaging machine with transparent bell RP series with solid steel structure, the latest generation of electronic, front control interface, intuitive programming, more space in the packaging space and a whole host of technical features that enhance performance yet. Three models are available with a support surface of mm. 400x250x200h - mm. 520x390x250h - mm. 580x780x250h. The dimensions of the support surface are to be considered with the hood closed. The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The full wrap packaging from Zappe ensures a perfect wrapping - for perfect sealing and schrinkage of goods of all kinds.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The full wrap packaging from Zappe ensures a perfect wrapping - for perfect sealing and schrinkage of goods of all kinds.

Request for a quote

KOMSILAJ MAKINE

Turkey

Our KMX 1000+ 60 silage baling machine has been designed for baling of beet pulp, corn silage and all other rough feed crops. According to the dryness rate and size of the grain particles the machine can bale 950-1000 kg. This machine can bale in 1 minute 1000kg and in 1 houre 60 tons approximately. The product has a positive role in making the life of farmers convinent and productive. Simultaniously the machine is capable of litter packing as well.

Request for a quote

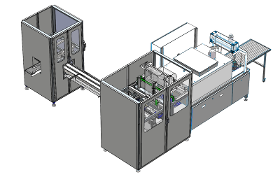

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Compared to the traditional shrink wrapper, our Flow Wrapping machine’s main features are high speed and less material waste, the speed has increased by 2-10 times, and you can save labor costs and time, it is suitable for bowl noodles, milk tea, cup products, frozen products, food boxes, cosmetics, clinker bottles, coil incense, and another shrink packaging. The product that has been packed with the film is sent to the automatic shrinking tunnel through the conveyor and run in the shrinking tunnel through the mesh belt, and the thermal energy efficiency during the operation can achieve the purpose of shrinking. The unit adopts a step-less speed regulation device; and cooperates with an automatic dual temperature controller to control the temperature, through the circulation of hot air, the quality of the shrinkage of the film is more stable and beautiful. The unit has high equipment efficiency, compact structure, reliable operation, low noise, and convenient maintenance.

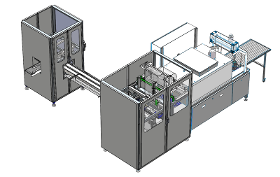

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Four sides horizontal wrap machine fully automatically wrap the products with 2 kinds of film or one kind of film but 2 rolls, consists of a special controller and touch screen for maintenance and control and 4 sets of servos.It is suitable for the packaging of solid sheet items in the pharmaceutical, health care, chemical, light industry, and food industries such as composite film, aluminum plastic film, a pure aluminum film, aluminized film, coated paper, etc., Bodywarmer stick, antipyretic stickers, infusions Heaters, pain relief plasters, medical accessories stickers, game cards, recharge cards, commemorative coins, kiss stickers, temperature measurement stickers, single-piece sanitary napkins, flaky tofu skin, spicy fish fillets, biscuits, etc.

Do you sell or make similar products?

Sign up to europages and have your products listed

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Side Sealer Shrink Wrap Machine is a fully automatic unmanned operation of an economic side sealing packaging machine, that is widely used in the assembly line of mass production and packaging. It uses an electronic eye to detect products as they pass through on the conveyor. After products pass, a single-sealing arm running perpendicular to the film closes behind the product. As the product continues to pass to the conveyor, a side sealing wheel makes the final seal enclose the product. The advantage of the side seal machine comes from the ability to wrap longer products. The width of the product is limited to the verticle sealing bar, but the length can be as long as needed. A perfect option for shrink wrapping molding, pipes, wood, and other elongated items. The horizontal knife in the sealing part adopts a vertical drive, and the vertical knife adopts a constant temperature side sealer. The sealing line is straight and firm to achieve a beautiful sealing effect.

MAKREV PACKAGING

Turkey

http://www.makrev.com/urunler.asp?LanguageID=2&cid=2

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Suitable for packaging soft, strip, and unorganized objects like towels, tissues, noodles, egg rolls, sausages, fish, ice-lollipop, soft candies, biscuits, fresh fruits, etc. Feature: 1. Double transducer control, flexible bag length cutting, the operator needn't adjust the unloading working, saving time and saving films. 2. human-machine operation, convenient and quick parameter setting. 3. Self-diagnosis failure function, clear failure display. 4. High sensitivity optical electric color mark tracking,digital input cut position which makes the sealing and cutting more accurately. 5. Separate PID control to temperature, suitable for various packing materials. 6. Stopping the machine in the selected position, no sticking to the knife, and no waste packing film. 7. Simple driving system, reliable working, convenient maintenance. 8. .All the controls are achieved by software, convenient for function adjusting and upgrading.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

This machine is used for packing candies as well as other solid products with regular shapes such as candies, lollipops,s, etc. Feature: 1. With a three servo touch screen control system. 2. With super plate feeding better and less empty package. 3. Durable structure design prolongs the machine using time and the machine can work separately, is easy to install, and is easy to maintain. 4. With double package rollers and an equipped paper splicer system, the film packaging can be used continuously without a stopped machine. 5. You can choose a vibrator and stainless steel construction for your options. 6. High-speed work stable, low noise, nice package, good seal and the products can keep for a long time.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

This machine is widely used for packing sauce, honey, water, oil, month wash, or some liquid.Automatically measuring volume, making bags, filling, sealing, cutting, printing the lot number and cutting easy tearing notches,finished product conveying. Features: (1).Famous brand PLC control system,large touch screen,convenient to operate; (2).Film drawing down system by famous bland servo motor. (3).Advanced design,high precision and fast speed; (4).Various alarm system to reduce waste; (5).Photoelectric tracking system for precise bag length and position of film.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic L Sealer Shrink Wrap Machines are widely used in the assembly line of mass production and packaging. It is suitable for products of different widths and heights. It uses an electronic eye to detect products when they pass through the conveyor. After a product passes the sealing arm, the seals fully enclose the product in shrink film. After the seal, products continue to pass into the shrink tunnel. The shrink tunnel has recirculating heat to shrink the film to the product evenly. Fully wrapped products exit the tunnel, and the film is conformed tightly to the product. Using the original "OMRON" digital temperature controller with built-in PID function, the temperature of the sealing knife is extremely sensitive and accurate, and can be set at will. The sealing knife itself also has an automatic protection function, which can effectively prevent miscut packaging, and has an automatic alarm function, which greatly improves the safety of the operator.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s fully automatic counting and packing machine for Furniture kit and hardware spare parts.You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in bag and open the machine. Feature: 1. According to screw/special parts sample tailored to the vibration plates with precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, whole machine is more secure, stable, reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduce wastage. 4. It completes the whole procedure of metering, filling,bagging,date printing, charging(exhausting),counting automatically. 5. Unique design of the packing seal technology, make the sealing nice and strong. 6. Equipped with chain conveyor trailer,it can be feed by manual if the vibration plates is un-workable.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts like screws, bolts, nuts, washers, springs, and plugs. High precision and fast, save the labor cost you. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. The lot number or other printing information is an optional device. Feature 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Tabletop vacuum packaging machine suitable for electronic components, IC swashplates, semiconductors. Hardware, pharmaceutical chemical raw materials, food, meat, dry goods, vegetables, fresh fruits, beans and various fluids (such as with a small amount of liquid, semi-fluid, particles) and other materials, vacuum or nitrogen-filled sealing packaging. It can achieve anti-oxidation, anti-corrosion, anti-mildew, moisture-proof and other fresh-keeping and quality-preserving effects. Tabletop vacuum packaging machine adopts a vacuum chamber, which directly vacuums or fills the packaging bag with nitrogen, which occupies a small space and can be used on the counter at will. It is suitable for chain stores, supermarkets, specialty stores, laboratories, small or processed food production enterprises, etc. .Just step on the foot switch, then vacuum, inflate, seal, cool, etc., it is automatically completed at one time, and it is easy to use.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

One machine can make three bag types: Quad seal bag, pillow bag, and gusseted bag. Optional device: Euro slot hole punching device (make a hole on the top of bag), Nitrogen filling device Features 1. Imported plc full computer control system, full Chinese/English touch screen operating system, clear display of the working status and instructions 2. High Precision servo film system, smooth movement of the film, with photoelectric automatic positioning and tracking system, accurate positioning 3. Intelligent digital temperature control system, temperature-controlled stability, with teeth-shaped sealer, sealed firmly 4. Including automatic fault alarm display function, such as low temperature, no packaging film, colorless belt, no material, servo failure, colorless signal, glass protection door when opened automatically alarm or shutdown function 5. This machine and metering device can be completed automatically by metering, feeding, filling bag, date printing, and finished.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

This machine is suitable for small granules like coffee or tea. Feature: 1.The drip bag is able to hang on the edge of a teacup with a special drip bag design, 3 side sealing type, which is better to brew the coffee or tea, beautiful bag style which is popular in the market. 2.Machine fully automatic make a bag, dosing, filling, sealing, cutting and counting bags, the printer is options. 3.Adopt a precise control system, compact structure, intelligent interface, friendly operation, convenient adjustment, and easy maintenance. 4.Adopt a servo motor for the inside bag length control, precise positioning, and stable bag length. The outside bag is elegant with photoelectrical positioning and a step motor for pulling the film. 5.The material inside the bag is a nonwoven fabric which is safe and convenient. Use the advanced ultrasonic sealing method to keep tight sealing and elegant bag. The outside bag is the hot sealing method. 6.Gas Nitrogen inside the coffee bags is an option.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The automatic continuous stretch vacuum packaging machine is mainly formed by heating and stretching through the lower film, then filling the packaging into the formed lower film cavity, and then entering the heat sealing vacuum chamber to vacuum or inflate the packaging, and put the upper. The film is heat-sealed with the lower film to form a packaging bag, and the packaging is divided by cross-cutting and longitudinal cutting. The finished product output of packaging can be completed automatically at one time, the operation is simple, the labor force is greatly reduced, and the difficulty of recruiting is solved, thereby improving the product quality, beautifying the production environment, improving production efficiency, saving time, labor, and efficiency, etc. Real automation equipment. Application: All kinds of meat,fresh meat, aged meat, sausages, Seafood fish,Dried fruits,Vegetables ,Ready to eat meals,Cheese, Pasta, noodles totally dried cereals, corn kernels, peanuts, etc.

Results for

Pack wrapping machines - Import exportNumber of results

42 ProductsCountries

Company type