- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oil mist separators

Results for

Oil mist separators - Import export

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separator – extraction systems for vapours Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Greater efficiency high performance separation media Our oil separation media feature a unique bonded fiber technology that can perform the function of multiple layers of traditional filter media, efficiently separating oil mist from the air stream. Our bonded fiber can also separate water from diesel and other fuels. With its gradient density structure, our reliable, efficient media can replace several layers of traditional media used in water separation. Specifically designed to reduce vehicle emissions and to improve performance, our powertrain filters come in two different types of solutions that can be provided in both custom and standard options: Our unique bonded fiber structure can efficiently separate over 95% of oil mist from oil reservoir fumes. Efficiently removes water from fuel streams that can cause issues with injectors and engines Increase efficiency, as POREX ® media can perform the function of multiple layers of traditional separation filter media request...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POREX TECHNOLOGIES GMBH

Germany

Greater efficiency high performance separation media Our oil separation media feature a unique bonded fiber technology that can perform the function of multiple layers of traditional filter media, efficiently separating oil mist from the air stream. Our bonded fiber can also separate water from diesel and other fuels. With its gradient density structure, our reliable, efficient media can replace several layers of traditional media used in water separation. Specifically designed to reduce vehicle emissions and to improve performance, our powertrain filters come in two different types of solutions that can be provided in both custom and standard options: Our unique bonded fiber structure can efficiently separate over 95% of oil mist from oil reservoir fumes. Efficiently removes water from fuel streams that can cause issues with injectors and engines Increase efficiency, as POREX ® media can perform the function of multiple layers of traditional separation filter media request...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Greater efficiency high performance separation media Our oil separation media feature a unique bonded fiber technology that can perform the function of multiple layers of traditional filter media, efficiently separating oil mist from the air stream. Our bonded fiber can also separate water from diesel and other fuels. With its gradient density structure, our reliable, efficient media can replace several layers of traditional media used in water separation. Specifically designed to reduce vehicle emissions and to improve performance, our powertrain filters come in two different types of solutions that can be provided in both custom and standard options: Our unique bonded fiber structure can efficiently separate over 95% of oil mist from oil reservoir fumes. Efficiently removes water from fuel streams that can cause issues with injectors and engines Increase efficiency, as POREX ® media can perform the function of multiple layers of traditional separation filter media request...

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The ISOG 20 is a timeless high-quality machine – and has been for years. Its further development focused on three main points: flexibility, precision and productivity. The basic version is convincing with its well thought-out basic equipment. — grinding spindle ISOG 20 F31: peak power 9 kW — infinitely variable speed control 1,000 to 8,000 rpm — coolant nozzle ring on the grinding head — wheel changer (SKW) 6-fold — indirect measuring system — cabinet cooling (active cooling unit) — direct drive in all rotary axes — central lubrication — MTS mill package — MTS drill package — MTS extension multi-spiral tools — electronic measuring probe — electronic handwheel — rated break point (spare part) — feeler insert diameter 1 mm — probe tip 12 mm — connection for external systems — (coolant system / oil mist separator

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

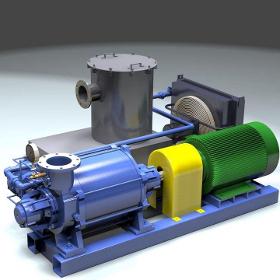

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quote

ROTORSTECH

Slovakia

Plants of these types are intended: - for the separation of liquid mixtures, which consist of two liquids, with the simultaneous removal of solid particles contained in liquids - to remove solid particles from a liquid (clarification) - for purification of mineral oils having a viscosity at a temperature of 50°C not more than 65 mm2/s - for use in power plants, substations, other energy facilities and at enterprises involved in the regeneration of technical oils

Request for a quote

INTEGRATEDAIR SYSTEMS

United Kingdom

For many workplaces, machine oil is used as the lubricant or coolant that keeps parts from wearing, saving time and money by decreasing the need for repairs. However, one of the inevitable by-products of pumps, compressors, turbines and other machines using oil is oil mist.

Request for a quote

OMEGA AIR

Slovenia

WOSm water oil separators have been developed to separate lubricant oil from condensate generated in compressed air systems. Due to patented technology regular service can be done in 30 seconds without any cleaning. Separation begins in “cyclonic depressurization chamber” and continues in “filter cartridge”. When the “filter cartridge” is fully saturated you just simply unscrew complete cartridge and replace it with new one. All the condensate stays in old cartridge which can also be sealed with plastic cover and disposed according to local directives and laws.

Request for a quote

OMEGA AIR

Slovenia

WOS water oil separators have been developed to separate lubricant oil from condensate from compressed air systems. WOS water-oil separator can be used in variety of applications. For applications not listed please contact us or your local distributor.

Request for a quoteResults for

Oil mist separators - Import exportNumber of results

14 ProductsCompany type