- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nozzle heaters

Results for

Nozzle heaters - Import export

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heating system especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our Freek heat transfer nozzle heater alternative is brass, with or without coating, preferably with a slit. The slit allows the assembly of an external bendable thermocouple and facilitates the disassembly, e.g. in case of a revision and can be coiled over. This is not possible at competitor's nozzle heater solutions. Freek's tight coiling at the heater's ends provides a maximum possible power concentration (patented).

Request for a quote

FRIEDR. FREEK GMBH

Germany

Owing to their small cross-sectional dimensions, MicroCoils are most often connected at both ends and do not permit the addition of a thermocouple. We prefer to use nickel as the sheath material here because it combines the best thermal conduction properties, high corrosion resistance and excellent deformation properties. To ensure that the standard 1000 mm PTFE-insulated connection cable can be positioned at one end, despite the standard two-ended connection of the element, in most cases the MicroCoil is formed into a hairpin shape and wound/laid in a bifilar (parallel) format. Our unformed MicroCoils are also supplied in the hairpin bend shape as standard.

Request for a quote

FRIEDR. FREEK GMBH

Germany

HotCoils have a larger cross-sectional area and are thus capable of greater power than MicroCoils. For this reason they are used in hot runners with adequate space and where high heat densities are required. Owing to the large number of variants and for cost reasons, the sheath material for HotCoils is stainless steel - the standard for the market and thus also for Freek. HotCoils are large enough that thermocouples can be integrated into them. Our standard here is Type J (Fe-CuNi; red/blue), while Types J and K are also available conforming to the IEC and ANSI standards (see colour codes). Since the measurement point of a built-in temperature sensor is situated in the heater and never where the heat is actually required, a HotCoil with a thermocouple makes particular sense where the application allows the use of larger processing (temperature) windows or where the installation location or the design requires protection against overheating.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek-MicroCoil 1.3 x 2.3 mm used in the "Brazed-Together" energy-saving nozzle heater is wound tightly onto a precision tube with good thermal conductivity and encapsulated and thermally insulated by means of an outer housing. For even more reliable heat transfer, the heater can optionally be vacuum brazed. The "Brazed Together" design combines many advantages: high accuracy, good heat conduction, high power density, mechanical stability and, last but not least, up to 20% higher energy efficiency. Freek is one of the technology leaders in the field of hot runner heating and supplies the who's who of the industry. Energy efficiency is one, if not the central innovation topic here. Manufacturers of high-cavity PET hotrunners and moulds in particular benefit from the BT nozzle heaters, and in several ways: because the less energy that is put into the system, the less energy has to be taken out on the cold side, the mould. This saves even more energy and shortens the cycle time.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Characteristics of our HotMicroCoils with reflection tube are easy mounting and variable heat distribution. Because of its direct touch and toleranced fit, the sleeve coil heater allows a very good heat transmission to the nozzle. In all our HotMicroCoil heaters with reflection sleeve the assembly of a thermocouple is possible and recommended for bigger diameters and power.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Especially for high-cavity PET plastic injection moulding there are various industry standards of clamp-band nozzle heaters available. Most common are the Axial Clamp-Band Heater and the Two-screw Clamp-Band Heater. Our HotCoil cable heaters with clamp band represent a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides its own systems Freek also manufactures original Rosemount-systems that can also be used as "Husky-replacement heater" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Both systems can be supplied with MicroCoils in "Rosemount style" (Ø 1,4 mm) as well as MicroCoils in "Freek style" (1,3 x 2,3 mm).

Request for a quote

FRIEDR. FREEK GMBH

Germany

Our Locking System provides a quick, easy and reliable clamping of the heating element on the nozzle to be heated. It facilitates an effective heat transfer, as the inside sheath is pressed to the nozzle with a high level of precision creating an interference fit. Due to the method of construction of the lock, installation is possible in the restrictive space of small cavities. The lock can be operated quickly and efficiently with simple readily available tools.

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

In all industry sectors, where heat is part of the production our products will be found. On injection moulding machines and extruders, for plasticizing of synthetic granules also for sealing of covers in packaging machines with diverse cup-geometry our heating elements deliver the heat. There are numerous applications, where our electrical heating elements are in operation. Our extensive product range of Temperature Sensors, Controllers as well as Ovens make our programme of delivery complete.

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

Introducing Caldor's Nozzle Band Heaters, the ultimate solution for precise and efficient heat transfer in injection molding and extrusion processes. Our robust heaters are engineered to deliver outstanding performance in various industrial applications, ensuring optimal material processing and end-product quality. These heaters are constructed with high-quality materials, providing a compact design and excellent heat distribution. The use of advanced ceramic insulation minimizes heat loss and enhances energy efficiency, while the built-in thermocouple ensures precise temperature control. Key Features: Customizable dimensions to fit various nozzle sizes Temperature range: up to 450°C Wattage: up to 100 watts per square inch Uniform heat distribution for consistent results Durable construction for long service life Easy installation and maintenance

Request for a quote

FRIEDR. FREEK GMBH

Germany

Spare Heaters suitable for hotrunner nozzles of familiar OEMs: Clamp Band Heaters for Husky Art-No. 520156, 521334, 534192, 534445, 534233, 534234 Kappa heaters for Husky 1250 series,(Bi-Metal, Bi-Metal with TC, Ultra 1250) for Husky 750 series (Bi-Metal, Bi-Metal HTR S/A, Ultra 750) for Husky 500 series (Ultra 500, Copper Ultra 500) Reflection tube nozzle heaers for Husky 500 series (500 HTM Brass) for Mastip MX series (MX13, MX16, MX19) for Mastip DX/MJ series (DX09, MJ09) for Mastip

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heater type especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our patent pending Freek heat transfer alternative is brass, with or without coating, basically with a slit. Characteristics of our HotMicroCoil nozzle heaters sheathed by a reflection tube are easy mounting and variable heat distribution. Because of its direct touch and toleranced fit, the heater allows a very good heat transmission to the nozzle. In all our HotMicroCoils with reflection tube the assembly of a thermocouple is possible and recommended for bigger diameters and power. Also most common nozzle heater solutions are HotMicrocoil heating elements with clamp bands with diverse locking mechanisms.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides their own clamp-band designs Freek also manufactures original Rosemount clamp-bands that can be used as "Husky-replacement heaters" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Freek has all the various industry standards for clamp-band nozzle heaters in Ø19,05 and Ø22,40 in their assortment, too. HotCoil minitubular heaters with clamp band are a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

FRIEDR. FREEK GMBH

Germany

In linguistic usage occasionally the terms coil heaters, nozzle heating elements, hot runner heating elements, cable nozzle heaters are used. Our HotMicroCoil heating elements can be used in a wide variety of applications. Their high level of plasticity ideally suits them to the heating of hot runner nozzles and for accurately heating the contours of three-dimensional surfaces. Many of our customers order HotMicroCoil elements in their unformed state of mineral insualted cable heaters and perform the subsequent shaping work themselves, while others commission us to shape and fit the heating cable elements. A large number of ready-to-fit heating solutions are available for plastic injection nozzles with clamping mechanisms, housing bezel, reflection tube or heat conduction sleeve.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Heating bands are the ideal solution for the heating of tubes an cylinders. Mica band heaters, frequently used as nozzle heaters, are made with a plastic-tight stainless steel casing. Such mica heating bands are in many dimension available from stock. The Ceramic heating band type is suitable specially for applications with high watt density and therefore for higher temperatures. Ceramic band heaters, also known as ceramic ring heaters or cylindrical ceramic sectional heaters, are attached to the contact surface by means of a clamping mechanism. A preferred field of use for ceramic band heaters is the heating of plasticising cylinders, bushings and nozzles of injection moulding machines and screw barrels of extrusion machines. For thermal optimization and process control ceramic band heaters can also be offered with insulation jackets or air cooling.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

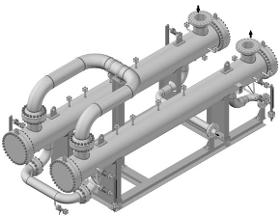

CHARACTERISTICS optimum thermal efficiency optimum efficiency of the turbine optimum load-case design flow optimized design vibration-optimized design OPTIONS custom specific design on international design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) design acc. to TEMA custom specific TPIs (Inspections / Third Party Inspections) custom specific testings sour gas application (NACE) temperature range -50 °C till + 350°C custom specific nozzle orientation GENERAL Performance Heaters, type VEV-LS are serially arranged heat exchangers, which heat up gas for a subsequent system requirement. Performance heaters can also be designed as coolers in reverse. The design is carried out as a steel welded construction in a horizontal design. FUNCTION Fuel Gas Performance Heater Type VEV-LS are used in high efficient combined-cycle gas and steam power plants (CCPP).

Request for a quote

SEIKI DEUTSCHLAND GMBH

Germany

Seikis valve gate nozzles are available with independent heating of the nozzle tip and the shaft. The can be controlled individually and, therefore, synchronized with the injection for less wear and tear and a clean closure of the nozzle.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Nozzle heaters - Import exportNumber of results

17 ProductsCountries

Company type