- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- multiple machining

Results for

Multiple machining - Import export

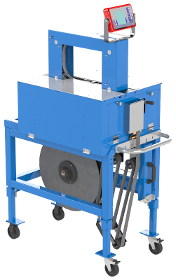

ATS-TANNER BANDING SYSTEMS AG

Switzerland

Banding machines that can handle multiple band widths.

Request for a quote

NORELEM FRANCE

France

The collet is opened by applying compressed air to the "open" port. The collet is closed (for clamping) by applying compressed air to the "close" port. The pneumatic connections can be screwed on either from below or from the side. If the air is connected from below, the side ports must be closed. Machining the collet for external clamping: The negative form of the workpiece to be clamped is machined into the collet. Free-form and asymmetrical contours are possible. Different workpieces can be clamped quickly and securely by simply exchanging the collet. The collet can be milled down to height H2. This enables multiple workpiece contours to be machined into one collet. Repeat accuracy for workpiece: +/-0.03 Repeat accuracy after replacing the collet +/- 0.02 The collet radial clamping travel is 0.15 mm per clamping segment. To prevent damage the collet should not be tightened without a workpiece or clamping ring in place. The operating air pressure should lay between 0.45 - 0.55 MPa.

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling machine for viscous products 6-lane machine with multiple product chambers for ready-to-serve meals in plastic or aluminium trays Machine performance: 40 cycles/min. 240 trays/min. 14.400 tubs/h Special features: Sterile air hood in filling area Tray magazine 2 x 6 dosing pumps with motorised individual adjustment from 0 – 500 ml Manual filling channel for insertion of products that cannot be filled 2 film applicator stations 2 sealing stations

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

wheel shaft manufactured by sliding head CNC multiple axis lathe machining material: stainless steel 303 diameter: 10 mm length: 258 mm Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

LANTECH

Netherlands

Extended Wrap Height Increase the wrap heights of your loads. Replace the 203 cm (80") mast with a 279 cm (110") mast. 220 V - 50/60 Hertz 15 AMP Adds a transformer to the machine. Cold Environment Operate in temperatures below -1 C to -18 C (+31 F to 0 F). Pallet Grip® Makes a "cable" of film that locks the load to the pallet. The film cable decreases the risk of damage during shipment. Click-n-Go® Remote Control Start or stop the machine from the forklift or other location. Note: You can use the remote for multiple machines. NEMA 12 Enclosure Keeps moisture, dust, and dirt from electrical components. Ramp Put the load on the turntable with a forklift or a pallet jack. EZ Weigh™ Integrated Scale Weigh and wrap loads in one step with a scale built into the turntable. Forklift Stop Helps the operator align the load on the turntable. Pit Mount It lets the operator put the load on the turntable at floor level. This is available for 1651 mm (65") and 1829 mm (72") turntables. Note:...

Request for a quote

LANTECH

Netherlands

Extended Wrap Height Increase the wrap heights of your loads. Replace the 203 cm (80") mast with a 279 cm (110") mast. 220 V - 50/60 Hertz 15 AMP Adds a transformer to the machine. Cold Environment Operate in temperatures below -1 C to -18 C (+31 F to 0 F). Corrosive Environment Operate in corrosive environment. It is for machines with exposure to agents such as salt and fertilizer. Click-n-Go® Remote Control Start or stop the machine from the forklift or other location. Note: You can use the remote for multiple machines. Wrap Arm Speed 1-15 RPM Allows the wrap arm to rotate up to 15 RPM. Note: This option includes Power-Roller Stretch Plus and increases the pre-stretch to 250%.

Request for a quote

VAN EYCKEN - METAL CONSTRUCTION

Belgium

At Van Eycken in Tienen, we introduce our advanced laser services, powered by our state-of-the-art FG-400 NEO tube laser from MAZAK. This machine, launched in 2022, is designed for high-quality 3D cutting of tubes, pipes, and structural material up to 15 meters in length. With various advanced technologies, the FG-400 NEO offers unparalleled operability and flexibility, resulting in highly efficient cutting work. The 3D cutting head with dual axis can handle a wide range of materials at any desired angle. The 4-jaw chuck system ensures stability and precision during cutting by preventing material deformation. The FG-400 NEO stands out by performing multiple processes in one machine, from 3D cutting to drilling and tapping. This versatility provides you with a complete solution for your laser processing needs, saving time and reducing costs.

Request for a quote

YMCUP

Turkey

YM/KBM-DK80 Series paper cup forming machines are automatic environmetal machine with multiple program structure. The materials used, such as paper, silicone oil, are completely healthy and environmentally friendly. Our machines are suitable for the use of SINGLE-AND DOUBLESIDED PE COATED paper. It is the ideal equipment for the production of cups used in every area of your life, providing ease of use with hot and cold beverages.

Request for a quote

LVD

Belgium

MOVit Warehouse Automation System (WAS) provides the ultimate in automatic material storage and retrieval with a customizable number of tower storage units beginning with a minimum of four towers, in a single or double row configuration. WAS keeps sheets in continuous flow for uninterrupted production and full lights-out operation, and can be connected to multiple laser cutting machines. KEY FEATURES Allows full lights-out production for high productivity Can feed multiple lasers Customizable number of towers, starting at a minimum of four towers Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Direct unload station Input/Output (I/O) station Simple output station Extended output station MODELS Available for Phoenix and Electra series (WAS 3015 and WAS 4020)

Request for a quote

CENTER OF INFORMATION TECHNOLOGIES NELIAN LLC

Russia

Dianel5122 BioResonance NLS Diagnostic and Therapy Machine with full Biofeedback and psychophysiological testing of Somatic Health for Integrative and Holistic Medicine practitioners with high visualisation level. Dianel5122 machine is for integrative and holistic medicine practitioners in with a high level of visualization with the functions Bioresonance NLS diagnostics of the human body up to 1000 organs, tissues, cells, microstructures, that reveals pathological processes in the body, hidden and chronic; Identification and localization of pathological processes at an early preclinical stage, Normalizing endogenous energy information therapy (EIFTherapy); Destructive antiviral and antimicrobial therapy that suppresses the vital activity of microorganisms; MultiEIFTherapy in automatic mode in 1 click on the list of selected organs and microorganisms

Request for a quote

STARRAG GMBH

Germany

s230 is an automatic solution for faceting and diamond finishing dials index. s230 production center allows the production of a wide variety on index in various metals. Contrasts of different visual effects are performed by the use of diamond tools or solid carbide tools. The complete solution for small and medium series for finishing index combines multiple operations on a single machine. Features Optical recognition and origin definition of blanks Diamond with the revolver toolholder Machining of LuniNova pockets and micromilling Simple programming interface on Windows A variety of automation systems are available to ensure a high level of autonomy in production

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION the machine has been made with a compact design. Machine can handle multiple bottles type and size. Capping and closing star system (for compact design). Servo star system. Servo closing system. Bottles Sterilization system SPECIFICATION 2 Filling nozzles Servo conveyor system included Type of metal used S.S 316 for all product contact metal parts & S.S 304 for all uncontacted product parts HMI and Scada system. Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION The machine which works with motor–belt mechanism, ideal for the serial end milling operations on aluminum and PVC profiles precisely. High quality end milling operations by means of the adjustable motor speed thanks to the inverter and potentiometer. Practical change of cutter provides ease of operation Fixing the workpiece firmly and at square by means of the vertical clamps and adjustable horizontal supports Safety operations with safety guard Cutter storage location in front of the machine Robust machine stand and support arms in front of the machine to provide end milling of profiles up to 2.5 meters Practical cutter adjustment by means of the gap parts Max. end milling profile height (H): 210mm Max. end milling stroke (W) : 615 mm Max. saw blade diameter: Ø185 mm Max. tool height : 150 mm STANDARD ACCESSORIES • 12x pneumatic vertical clamps with adjustable pressure valve • 6 x adjustable horizontal supports • Air gun

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2 and/or the Handformer HF 100. This Multiformer MF 500 EW consists of: English wheeling machine MF 500 Optionally available with a Handformer HF 100 for shrinking and/or a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the Handformer HF 100. This Multiformer MF 500 GL 2 consists of: English wheeling machine MF 500 + planishing hammer GL 2 Optionally available with a Handformer HF 100 for shrinking (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2. This Multiformer MF 500 MAX consists of: English wheeling machine MF 500 + Handformer HF 100 for shrinking For our Handformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Optionally available with a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer switch divides the stream of products into two or more lanes during continuous operation or in cycle operation. You can select either a pneumatic or an electrical drive. The pneumatic drive is characterized by a good price-performance ratio. The electrical drive allows you to divide the stream of products into more than two lanes. Technical data: —Distribution: 2 lanes —Distribution process in cycle operation —Lane distance: up to 250 mm —Pneumatic drive Optional equipment: —Independent electrical control system with congestion monitoring —Loading and unloading belts —Infinitely variable width adjustment —Combination with gripper technology for distribution during continuous operation —Electrical drive for distribution to multiple lanes —Complete machine cover made of Makrolon with maintenance doors

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DR. JOHANNES HEIDENHAIN GMBH

Germany

How can you improve manufacturing productivity? Does it make sense to invest in a new milling machine? Are you able to keep track of machine statuses during multiple-machine operation? With its comprehensive machine data acquisition (MDA) and intelligent process analysis capabilities, StateMonitor helps you optimize and bring greater transparency to operational processes. The software displays the production statuses of your machine tools in real time. Extensive notification and evaluation functions help you uncover hidden potential and improve efficiency. You maintain a constant overview that allows you to react swiftly to production disturbances. As a result, you avoid unnecessary downtime and bottlenecks while improving machine utilization and availability. Regardless of where you are, you can even access machine data on your smartphone or tablet. StateMonitor can connect CNCs that use the following protocols: HEIDENHAIN DNC, OPC UA, MTConnect, or Modbus TCP.

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s highly versatile microFLEX™ product family is the all-in-one solution for manufacturing flexible thin films in photovoltaics, electronics, medical devices, displays, and semiconductors. The production systems can handle various substrates, material thicknesses, and types such as polymer films, stainless steel, and thin glass. The microFLEX™ systems combine high precision laser processing with cleaning and packaging technologies, as well as inline quality control. Due to its modular concept, various customized solutions are available, reaching from industrial mass production to pilot lines as well as applied research. High throughput and efficiency on-the-fly processing; high machine uptime; multiple tension controllers; contactless substrate guiding Highest flexibility easy machine layout modification by modular concept Cost advantages Long term security of investment; reasonable cost of ownership; easy to upgrade and modify; different micro environments.

Request for a quote

KOMAX HOLDING AG

Switzerland

The Kappa 331 is a modular cut and strip machine with a rotating blade module. Round, multilayered cables – with and without shielding – are precisely stripped in multiple steps. The machine can be changed over quickly, making it ideal for flexible use. The Kappa 331 automatic cut and strip machine is used for round conductors with a cross section of 0.22 to 35 mm² (AWG23 – AWG2) and for specific applications up to 50 mm². It performs full and partial pull-off operations on individual layers and strips the outer jackets from jacketed cables with outside diameters of up to 16 mm that are with or without shielding. The high efficiency results from the flexible configuration possibilities and the short conversion times. The Kappa 331 is ideal for work environments with highly diverse products made in large and small batches. Powerful belt or roller drives transmit forces in an optimum way for the widest various of jackets.

Request for a quote

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OSR bag packer and packaging machine can handle tissue products of all types, supporting all required roll product formations of kitchen towels and bathroom tissue in one or multiple layers. Optima Nonwovens machines and modules are designed to meet your specific requirements. Bathroom tissue and kitchen towel rolls can be packed on Optima equipment in pre-made polyethylene bags. This is how Optima Nonwovens has maintained its status as a leader in the industry. Full servo technology Modular machine structure Taylor made solutions to match individual requirements Small foot print Quick and easy change-over Single and double layer packages possible Premade polyethylene bags on wickets Point of sale packages Carry-handle possible Perforation for easy bag opening possible

OPTIMA NONWOVENS GMBH

Germany

For packaging panty liners or sanitary napkins (regular or ultra thin), either flat or folded and wrapped, high performance and a huge variety of packages are in demand. Adapted to these requirements, only the best machinery offers maximum flexibility and ideal product protection. Fully automated machinery by the OPTIMA ON3/OS2 bag packer and packaging machine delivers the optimum process quality to deliver lowest cost per pack to our customers. Modular machine structure Multiple product rows possible Quick and easy change-over Premade polyethylene bags on wickets Tilting cassette

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA HS/OS7 bagger and packaging machine combines multiple decades of experience as the technological leader with unrivalled quality in machine engineering. The user’s individual requirements set the standard for how the packaging process is designed. With these high-performance machines, a multitude of new options are possible in the packaging process, for example for producing small packages at high speed. Multiple stack handling options Low count tilt module for low count bags Automatic lubrication system Motorized change-over High speed packaging

OPTIMA NONWOVENS GMBH

Germany

Whether compressed large packages or sales packages with excellent visual and haptic quality, this segment is characterized by strongly varying requirements. Modular packaging machines such as the OPTIMA LS/OS8 can meet all these needs at the same time. Industry-leading outputs combined with very high machine reliability ensure productivity, while additional quality control functions for both, process and product, further sets these units apart from the competition. The OPTIMA OS8 bagger can be ideally combined with the OPTIMA LS stacker. Not only can an unrivalled range of formats be flexibly processed with this system; the integrated modules and additional (control) functions open up a new dimension of packaging process design. Modular machine structure Multiple product rows possible Stack turning possibility Quick and easy change-over Premade polyethylene bags on wickets

TOTALENERGIES LUBRIFIANTS

France

Lubrication of cutting operations for multiple metals and machine tools.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

Storing or relocating the bars is fully automated by the Gantry System. It offers the operator the option to simultaneously store multiple different materials. The punching machine is automatically loaded with the stored materials depending on the order. As with other EHRT software solutions, the stock quantities and status of the gantry can be checked both at the machine and remotely from an office. This leads to a significant reduction in manpower requirements at the machine. Like the stock status, current orders can be traced from the office as well as the machine. Orders to the gantry related to storing, relocating, or retrieving materials and loading for production jobs can be executed simultaneously. The gantry can replace an existing material storage facility.

Request for a quote

CASEARTECNICA BARTOLI SRL

Italy

Automatic machine for cutting cheese into slices with variable or predetermined weight and dimensions. Versatile and flexible, the ROCK 20PLUS model is designed to work in line with other machines from Caseartecnica Bartoli or stand alone. Technical features Rock 20 Plus automatic for cutting cheese: Small size. Suitable for working in line with pre-existing machines or by Caseartecnica Bartoli, for the complete automation of the production cycle. Number of cuts programmable by PLC. Interchangeable bells, for the perfect centering of cheeses with different shapes. Quick and easy replacement of the bells. Fully automatic operating cycle. Easy-to-extract worktop to facilitate cleaning and sanitizing of the machine. Multiple recipes for various types of products and cuts. Special, interchangeable blades for cutting semi-hard, hard and very hard cheeses. Automatic weighing with external scale. Programmable fixed weight cutting.

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Product The centrifugal filter AEROIL has been designed for the separation of oil from the air sucked, through the principle of centrifugation and for an easy “machine-side” application, in the field of machinetools. In the mechanical work-processing where especially “heavy” oils are utilized , it can be employed separately by itself, in all other cases it is recommended to use it as the pre-filter of an electrostatic filter placed down-stream. The AEROIL with its limited dimension and weight can be installed onboard the machine, or over a raised platform previously arranged. Application Mechanical industry: multiple-operation-lathes, threading machines, toothing machines, grinding/refacing machines, etc. Graphic industry: typographic rotary press for newspapers (ink fogs), etc. Food processing industry: vegetal oil nebulizers, machines for pasta processing, etc. Other fields: turbines, compressors, pumps, lubricators, vaporizers, etc. The AEROIL separator looks...

Request for a quote

AGROSERVIS PROIZVODNJA D.O.O.

Croatia

MultiPlant is machine intended to transplant seedlings in ground. Usage of this machine, compared with manual transplantation, reduces needed labour and also transplantation time. Purpose of machine: - Semi-automatic transplanting of seedlings regardless of the conical, pyramidal or squared shape of the seedlings roots: o transplanting of vegetables o transplanting of herbs o transplanting of ligneous plants Machine properties: - semi-automatic transplantation - Possibility of transplanting on: o Bare ground o Previously prepared bed o Previously layed foil - regulation of working depth - transplantation of conical, pyramidal or squared shape of soil on the seedlings roots - adjustable distance of planting in one row - adjustable distance of planting between rows Working principle: 1. Worker on the machine fills the cups with plants 2. Cup puts plant in the soil 3. Plant presser wheel presses soil around plant

Request for a quoteResults for

Multiple machining - Import exportNumber of results

34 ProductsCountries

Company type

Category

- Paper and cardboard manufacturing - machinery and equipment (4)

- Forming - steels and metals (3)

- Laser - cutting and welding machines (3)

- Machine tools - metal machining (3)

- Machine tools, metal machining - parts and accessories (2)

- Packing and packaging - machinery and equipment (2)

- Agricultural machines and accessories (1)

- Cardboard - manufacturing machinery (1)

- Clamp collars, plastic (1)

- Conveyor belts (1)

- Food industry - machinery and equipment (1)

- Gantries (1)

- Lubricants, industrial (1)

- Mechanical engineering - custom work (1)

- Medical laboratories (1)

- Milking - machinery and equipment (1)

- Planting and sowing machinery and equipment (1)

- Rolling mills - machinery and installations (1)

- Shearing machine tools (1)

- Software for industry (1)