- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- moulding of plastic materials

Results for

Moulding of plastic materials - Import export

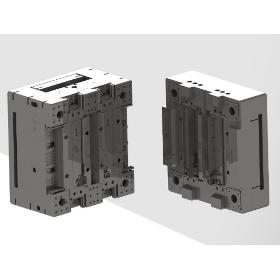

ACKOR MOULD LIMITED

China

Your relaible partner from China for injection molds & moulding parts with high- quality and cost-effective solutions. ISO 9001:2015 & IATF 16949 accredited

Request for a quote

IMPRINTA

Russia

Clotho ABS is a durable, composite, glass-fiber (13%) material that is heat resistant up to 100 °C. It was created to embody complex ideas even on simple personal printers. It is perfect for printing structural elements, functional parts, home products and car tuning. The material has an excellent surface of finished products without visible layers, minimal shrinkage and warpage, high printing accuracy, good adhesion to adhesive agents for ABS, easy post-processing, high modulus of elasticity.

Request for a quote

FELICITA

Ukraine

Plastic products for water recreationists. Made for manufacturer of boats, kayaks or other watercrafts. Wide range of products you will certainly find the very thing you have been looking for boats

Request for a quote

KULLEN-KOTI GMBH

Germany

Kullen-Koti disc brushes can be supplied with various fill configurations. For example with compressed face, with narrow or large fill collars, with fill array in particular forms, either with normal vertical bristle bundles or with inclined bundles to all directions. We supply core material according to your application purpose, for example cores made of plastic qualities PP, PA, PE, POM or PVC as well as of wood or different steel and metal types. On request of big quantities it is worth to use moulded plastic cores. Almost all fill material qualities can be used, e.g. natural hairs and bristles, plant fibres, synthetic filaments and wires. We can supply disc brushes matched to your requirements with bore hole, thread or shaft for fitting in the machines.

Request for a quote

RAMIREX - PLASTICOS DE AGUEDA, LDA.

Portugal

Ramirex - Plásticos de Águeda, Lda. is a Portuguese company with 40 years' experience in the field of plastic injection moulding, manufacturing in its own moulds - catalogue items, or in customer moulds - exclusive pieces. We produce a wide range of catalogue items, from furniture accessories (e.g. sofa legs, made-to-measure roller shutter doors, bats and tops), to drawing and office equipment (e.g. squares, rulers, protractors, paper trays, pen cups and magazine holders), and fencing material (e.g. fasteners and tops). We also manufacture specific and exclusive technical parts for various areas (e.g. for refrigeration equipment, switchboards and various telecommunications devices), designed and developed in-house or externally according to the needs of each client. We are at your entire disposal to develop solutions adapted to your needs.

Request for a quote

ACKOR MOULD LIMITED

China

We are factory for molds and molding products for plastic and metal material

Request for a quote

ACKOR MOULD LIMITED

China

We are factory for molds, molding products for plastic,rubber and metal material

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China injection molding factory custom all kinds of plastic products for world clients. Plastic wheel project: Plastic wheel barrow wheel process: plastic injection molding materials :Abs,POM, PVC,PC, polyethylene, nylon 6, nylon 66, polypropylene, copolymerized polypropylene, polyester, PD-PE, NBR, etc. Surface treatment: Deburring, ABS Chrome plated, vacuum coated etc. We are a professional plastic injection molding manufacturer from Ningbo China, we customize a variety of plastic wheels for all industries.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

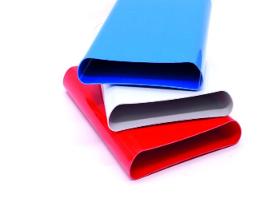

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,TPE/TPR, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Tansparent PC Pipes & PVC Profiles, High transparency, light transmittance up to 92%. Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides from PVC resins. The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic PC extrusion pipes or profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Tansparent PVC Pipes & PVC Profiles, transparency is customizable. Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides from PVC resins. The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic PVC extrusion pipes or complicates structured profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

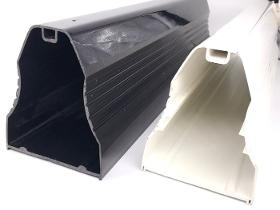

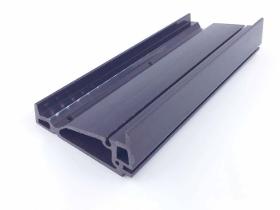

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic ABS extrusion profiles, pipes, strips, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides, The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any ABS extrusion profiles,welcome send your drawings or samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China plastic casters swivel wheel supplier, Soruce factory with lowest prices. Plastic casters swivel wheel, nylon casters with brake, locker process: plastic injection molding materials :Abs,POM, PVC,PC, polyethylene, nylon 6, nylon 66, polypropylene, copolymerized polypropylene, polyester, PD-PE, NBR, etc. Surface treatment: Deburring, ABS Chrome plated, vacuum coated etc. We are a professional plastic injection molding manufacturer from Ningbo China, we customize a variety of plastic wheels for all industries.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE,TPE/TPR... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion,Embossing Extruding, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For smooth cutting off of plastic moulded parts or soft materials such as lead • Cutting edge without side face • With adjustable cutting edge stop by means of adjustment screw (only model 133FG) • With opening spring • Handles coated with plastic • Made of special tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For smooth cutting off of plastic moulded parts or soft materials such as lead • Cutting edge without side face • With adjustable cutting edge stop by means of adjustment screw (only model 133FG) • With opening spring • Handles coated with plastic • Made of special tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For smooth cutting off of plastic moulded parts or soft materials such as lead • Cutting edge without side face • With adjustable cutting edge stop by means of adjustment screw (only model 133FG) • With opening spring • Handles coated with plastic • Made of special tool steel, forged, oil-hardened

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using extrusion blow moulding with the following characteristics: Volume: from 10 to 2000ml.; Materials: PP, PE, PVC, ABS, PS, POM, PA and others; Specialty bottles: bottles with a slanted neck, with a transparent line for content level control, high pressure resistant bottles and others; Industries: technology, cosmetics, chemical, automotive and others. We also offer a complete set of services that help in the manufacturing of plastic products and mould maintenance: Design, 3D model and a “Rapid Prototype”; Tooling; Mold servicing and repairs; Additional processing and assembly of plastic articles.

Request for a quote

PIR.SA.FA. S.R.L.

Italy

Founded in 1958, PIR.SA.FA. is a third-generation company that manufactures and sells accessories for shirts, clothing and leather goods. It is also involved in the moulding, processing, and blanking of plastics and PVC materials with the latest addition to our product range including candle holders and small candle holders. Its competence and professionalism in the field of plastic materials moulding makes PIR.SA.FA. the ideal partner for the moulding of pieces of a variety of sizes and craftsmanship, providing flexible solutions suitable for all possible manufacturing requirements. It has been involved in the moulding of candles/candle holders with third parties for a number of years and since July 2020 it has had its own candle holders and small candle holders.

Request for a quote

MDP TEAM

France

Injection, bi-injection and overmolding of technical and appearance parts Series from 100 to 1 000 000 parts Single and multi-cavity injection and overmolding Injection of structural parts Injection of appearance parts Injection of transparent parts Overmolding of inserts Finishing: painting, surface treatment,... Metrology follow-up

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We realize with customized plastic moldings. Our product spectrum ranges from the smallest precision parts through housings to complex multi-component parts. On the basis of your sample, your specification or technical drawing, we will create an individual offer and support you during the project. We advise you on the selection of suitable materials and offer cost reduction options. We offer you an active co-operation in the development and construction and give suggestions for improvement. For an offer we need: •technical drawing, sketch or pattern •technical specifications, equipment extras •required amount Please send following informations to: info@nh-technology.de One of our engineering experts will contact you asap.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Plastic Mold Industry Sector; It has developed with the widespread use of plastic. Our company, which closely follows these developments, has made many improvements and updates in the field of plastic mold / injection mold. By directing the design process, which is completed with great care, to the machine park, the necessary mold set for mold manufacturing is ordered. The raw material of the incoming mold set is selected according to the product and production type. Quality and efficiency are kept at optimum level in works that require high precision. In addition to injection molds within AYBERKSAN Plastic Mold Industry; ZPL, hot runner, blow mold, rubber press mold and insert mold are also produced. The mold designed in the CAM phase is programmed to be processed on CNC machines. At the same time, processes that require dimensional precision are reviewed. After programming, the mold is processed on the CNC machine.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quoteResults for

Moulding of plastic materials - Import exportNumber of results

69 ProductsCountries

Company type

Category

- Injection moulding of rubber and plastic (33)

- Plastics moulding (30)

- Moulds, plastic and rubber industry (14)

- Extrusion of rubber and plastic (11)

- Reinforced plastics - moulding (11)

- Blow moulding of rubber and plastic (5)

- Building hand tools, non-power (3)

- Testing equipment (3)

- Die casting moulds (2)

- Prototypes, industrial (2)

- Injection, plastics - machinery (1)

- Castors, swivelling (1)

- Machine tools, metal machining - parts and accessories (1)

- Plastic products for the electrical industry (1)

- Plastic products for the garment industry (1)

- Rubber and plastic - processing (1)