- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- molybdenum

Results for

Molybdenum - Import export

PLANSEE SE

Austria

Nuts made of molybdenum and the molybdenum alloy TZM are available in the Plansee Online Shop. Order fast and easily from the producer's online shop: www.plansee.com/shop

Request for a quote

PLANSEE SE

Austria

Rods made of molybdenum and the molybdenum alloy TZM are available in the diameter range 2mm to 165mm in different lengths in the Plansee Online Shop. Order fast and easily from the producer's online shop: www.plansee.com/shop. Special dimensions are available on request.

Request for a quote

PLANSEE SE

Austria

Tubes made of molybdenum are available in the Plansee Online Shop. Tubes are available in different lengths and diameters from 0,381 up to 1,52 mm. Order fast and easily from the producer's online shop: www.plansee.com/shop

Request for a quote

PLANSEE SE

Austria

Washers made of molybdenum are available in the Plansee Online Shop. Order fast and easily from the producer's online shop: www.plansee.com/shop

Request for a quote

PLANSEE SE

Austria

Sheets made of molybdenum and the molydenum alloys TZM, MLR and MLS are available in the thickness range from 0,127mm to 40mm in different sizes in the Plansee Online Shop. Order fast and easily in the producer's onlineshop: www.plansee.com/shop. Special dimensions are available on request.

Request for a quote

PLANSEE SE

Austria

Plansee charge carreiers from refractory metals are dimensionally stable at high temperatures and in contrast to graphite parts they are also suited for high-vacuum furnaces. MLR with its superior creep resistance and retained ductility after high temperature operations is the ideal material for mechanically loaded furnace parts. Plansee designs and fabricates furnace fixtures to customer specifications, e.g. for aeronautics, glass industry, Metal Injection Molding (MIM), commercial heat treatment and various other thermal processes. Alongside molybdenum and tungsten, we primarily manufacture our charge equipment from TZM and ML. The creep resistance of these alloys is ten times better than that of pure molybdenum and they are also exceptionally ductile. As a result, our charge systems are perfectly equipped to cope with frequent changes between high and low temperatures.

Request for a quote

PLANSEE SE

Austria

Plansee supplies sintering and annealing boats made of molybdenum, tantalum, niobium, tungsten and various alloys such as ML or TZM. They are dimensionally stable, corrosion resistant against many chemicals and have a very good creep resistance. Whether is is continuous or batch furnaces - Plansee has the right solution at hand. For best quality surfaces we supply sintering and annealing boats with coatings made of aluminum and zirconium. Plansee produces its boats according to the customer's drawing in different sizes and shapes.

Request for a quote

PLANSEE SE

Austria

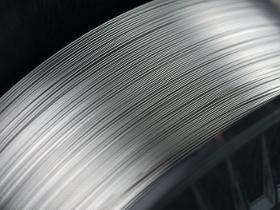

Wire made of molybdenum and molybdenum-lanthanum is available in the diameter range from 0,4mm to 3mm in the Plansee Online Shop. Order fast and easily in the producer's onlineshop: www.plansee.com/shop. Special dimensions are available on request.

Request for a quote

PLANSEE SE

Austria

Metallic heaters made from ML or tungsten are made for very high temperatures between 1000 °C (1 832°F) and 2 800 °C (5 072 °F). Plansee supplies heating elements for all types of high-temperature furnace in the form of ribbon, sheets, rods, twisted wire, wire bundles and wire mesh heaters. Plansee's materials belong to the group of refractory metals. Molybdenum and tungsten are the two materials that are most commonly used in high-temperature thermal processes. Thanks to their high melting points, they do not soften even at very high temperatures. Refractory metals have a lower coefficient of thermal expansion and better thermal conductivity than steel.

Request for a quote

PLANSEE SE

Austria

Molybdenum and tungsten crucibles from Plansee are the perfect vessels for melting and solidifying the single crystal. The formed crucibles have particularly thin walls combined with excellent creep resistance. The outstanding purity of the crucibles prevents any contamination of the single crystal. Even the most aggressive sapphire melts cannot do any harm. Plansee produces large numbers of formed molybdenum and tungsten crucibles and supplies them in all commonly used dimensions. They are successfully used by all the major manufacturers and numerous end customers worldwide.

Request for a quote

PLANSEE SE

Austria

Ribbons made of molybdenum, molybdenum-yttrium (MY-ESS) and molybdenum-lanthanum are available in the thickness range from 0,02mm to 0,762mm in different widths in the Plansee Online Shop. Order fast and easily in the producer's onlineshop: www.plansee.com/shop. Special dimensions are available on request.

Request for a quote

PLANSEE SE

Austria

Threaded rods and pins made of molybdenum and the molybdenum alloy TZM are available in the Plansee Online Shop. Order fast and easily from the producer's online shop: www.plansee.com/shop.

Request for a quote

PLANSEE SE

Austria

Molybdenum sputtering targets are used for the manufacture of thin-film transistors used in TFT-LCD screens. Targets from Plansee are maximum dense, highly pure and show a homegenous microstructure. Therefore higher sputtering speeds, minimized particle formation during the process and homogenous layers are guaranteed. Available molybdenum alloys: MoTa, MoNb, MoNa, MoW You can choose between our single and multi-piece planar targets. Planar targets are available for all commonly used systems as well as to specific customer needs. Rotary targets are available too.

Request for a quote

PLANSEE SE

Austria

Rivets made of molybdenum are available in the Plansee Online Shop. Order fast and easily from the producer's online shop: www.plansee.com/shop (Mo rivets)

Request for a quote

PLANSEE SE

Austria

Metallic hot zones are made for very high temperatures between 1000 °C (1 832°F) and 2 800 °C (5 072 °F). As a specialist in refractory metals Plansee delivers molybdenum and tungsten hot zones with an excellent form stability and lifetime. Plansee designs and produces hot zones for various types of furnaces (vacuum, protective gas atmosphere, HIP etc) and thermal processes such as sintering, brazing or annealing. Hot zones consist of countless individual parts such as heating elements, shield packs and hearth assemblies and charge carriers. You can find all of these components at Plansee. - Hot zones made from molybdenum, tungsten, tantalum, niobium and their alloys - Full metal or hybrid hot zones with graphite or ceramic fiber insulation - From very small (a few cm³) through to very large (several m³) hot zones - For temperatures of between 1000°C (1832°F) and 2800°C (5072°F) - Tailor-made design: round, rectangular, vertical, horizontal or special geometries

Request for a quote

PLANSEE SE

Austria

Molybdenum-hafnium carbide (MHC) is highly temperature-resistant, has a high level of thermal conductivity, a low coefficient of thermal expansion and a high recrystallization temperature. MHC retains its shape even when used at temperatures of up to 1 550 °C. At temperatures up to 800 °C, MHC is suitable for use in die inserts. At higher temperatures, the producer recommends using MHC for full dies. The benefits to you for a long service life: — Optimum nondeformability and dimensional stability — Low tendency to crack in the case of edged profiles — High thermal stability — High thermal conductivity — Low thermal expansion — Good hot ductility — Very high recrystallization temperature Plansee supplies MHC components in disc form with or without drilled start hole.

Request for a quote

PLANSEE SE

Austria

Electrodes made of molybdenum are used for the melting of glass by means of electrical energy. Plansee molybdenum electrodes have many advantageous properties: high purity, good form stability and high corrosion resistance to molten glass as well as a good electrical and thermal conductivity. Standard sizes are available from stock. Plansee supplies glass melting electrodes made from MoZrO2 for glass production involving particularly aggressive glass melts. Small quantities of zirconium oxide (ZrO2) added to molybdenum enhance the properties of the pure material.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EWG E. WAGENER GMBH

Germany

Molybdenum is a heavy metal which has a silver-white colour in piece form or a greyish colour in powder form. The stretchable and polishable heavy metal is hard and brittle, but still easy to process. Molybdenum belongs to the group of refractory metals with a melting point of 2.617°C. Molybdenum is mined mainly in North and South America and China. The metal is mainly extracted as a by-product of copper production. E.WAGENER supplies molybdenum in various shapes, alloys and processing forms. Suitable for your particular application.

Request for a quote

OEN CHEMICALS GMBH

Austria

Chemical appearance BLK – 301 has a type of dark brown or amber colour and comes in a liquid form with an oily consistency. It is dissolvable in water and has a density of 1.080 – 1.120 g/m3 and a pH level of 10 – 13. Chemical application and strength BLK – 301 is another great collector in the flotation process of silver, copper, zinc, gold, and molybdenum sulfide. Very soluble in water. It has weak power in the collection of pyrites but is has an excellent selectivity to silver, copper, and gold ores. Only small dosage is used in the flotation process but the BK – 301 still exhibits excellent collection power and great selectivity. It has some frothing characteristics It should be placed in an environment away from exposure to water and extreme heat from fire and sunlight. It should always be placed upright and never upside down

Request for a quote

NOVAFRUIT & ABONOVA

Spain

Floranova will be used dissolved in water both foliar and irrigation in all types of crops at the indicated doses. It is compatible with most fertilizers and phytosanitary products. It is not recommended to mix with oils, sufocalcium mixtures or products with a strong alkaline reaction. It is recommended to do a small test before mixing in the tank.

Request for a quote

PLANSEE SE

Austria

Evaporation coils are available in many different lenghts, diameters, coil lenghts and coil pitches. These resistance heaters with their very high melting points will bring practically any metal to the boil. At the same time, their high corrosion resistance and outstanding material purity prevent any contamination of the substrate. The range includes evaporation coils made of the following materials: — Grain stabilized tungsten (WVM) for the evaporation of aluminum — Tantalum — Molybdenum — Molybdenum-lanthenum (ML) for particularly long service lives

Request for a quote

PLANSEE SE

Austria

During the aluminum casting process, the metal melt is either poured or pressed into the mold. This process is used, for example, to manufacture cylinder heads, wheel rims and many other aluminum castings. Here, the mold has to repeatedly withstand the metal melt at a temperature of over 600 °C: for inserts made of our tungsten-heavy metal alloy Densimet® and the molybdenum alloy TZM, that's not a problem. The benefits to you: — Shorter cycle times — Top surface quality for your products — Long mold service life — No cracks in the mold insert Tailor-made mold inserts, sprue bushes, cooling inserts and other individual parts as well as semi-finished products for your mold are available.

Request for a quote

PLANSEE SE

Austria

Evaporation boats made of tungsten, molybdenum and tantalum are available in many different widths, lenghts, material thicknesses and volumes directly in the Plansee Online Shop: www.plansee.com/shop. Special dimensions are available on request.

Request for a quote

PLANSEE SE

Austria

Welding electrodes made of tungsten, molybdenum and their alloys are particularly suitable for welding highly conductive materials such as copper. They are used in the following processes: Spot welding, Roller welding, Projection welding, Upset welding. Welding electrodes made from our refractory metals and their alloys have a relatively high level of electrical conductivity while also exhibiting outstanding stability at high temperatures. They therefore have a considerably longer service life than conventional materials such as copper and copper alloys.

Request for a quote

PLANSEE SE

Austria

For the high-resolution devices used in general X-ray applications, mammography, angiography and computed tomography, Plansee develops and manufactures extremely robust X-ray anodes and components for X-ray tubes. The product range includes anodes made from molybdenum alloys such as TZM and MHC with focal tracks consisting of various tungsten-rhenium alloys. Plansee manufactures molybdenum-vanadium and molybdenum-niobium targets that are specially designed for use in mammography applications and which can be optionally equipped with precious metal focal tracks. The product range also comprises material combinations including copper and precious metals and brazed graphite elements on the metallic disc. As braze materials V/Ta/Zr composites, titanium, zirconium and other materials are used. Plansee supplies anodes as ready-to-use assemblies including the rotor, heat shield and shaft.

Request for a quote

PLANSEE SE

Austria

Nozzle tips for hot runner nozzles made of titanium-zirconium-molybdenum offer particularly high thermal conductivity of 140 W/mK coupled with excellent temperature and corrosion resistance. Glass fiber-reinforced plastics are exceptionally strong during processing but also highly abrasive. An optimum combination of thermal conductivity and material hardness is required. The TZM nozzle tips of Plansee are exceptionally resistant to aggression: the SHN surface hardening process. Using SHN surface hardening, we can strengthen peripheral areas and entire TZM components through the addition of a permanent, adherent diffusion layer. As a result, our customers benefit from the use of a tough, heat-resistant material with a wear-resistant surface. Surface hardening takes place during the gas phase. Coatings that we produce using the SHN process adhere better than conventional PVD or CVD layers. They perfectly replicate the surface contour of the TZM product.

Request for a quote

PLANSEE SE

Austria

Spare parts include for example chambers, filaments, arc slits, holders and many other parts. The pare parts are made of graphite, molybdenum, tungsten and alloys. They are extremely durable and long lasting and therefore save money and maintenance time. 100 or more Plansee components are at work in every beam path. They ensure that the ions are generated efficiently and guided precisely and free from impurities along the beam path to the wafer. For customers in the semiconductor industry, Plansee spare parts are increasingly becoming more than just spares. Taking the equipment manufacturer's original spare parts as starting point, Plansee optimizes the geometries and material compositions. The benefits to you: — Simplified component installation and removal — Longer service lives — Lower cleaning costs — Reduced maintenance work — Reduced downtimes

Request for a quote

LABORATOIRE NUTERGIA

France

OLiGOMAX Molybdenum is a synergy of naturally-sourced minerals and trace elements: a combination of concentrated sea water with lithothamnium and red algae, a source of trace elements. It contains trace elements selected for their benefits, including molybdenum. Molybdenum contributes to maintaining the normal metabolism of sulphur amino acids.

Request for a quoteResults for

Molybdenum - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Steels and metals - surface treatment and coating (4)

- Scrap iron - salvaging and recycling (3)

- Steel & Metals (3)

- Industrial furnaces (2)

- Bars - non-ferrous metal (1)

- Boarding, metal (1)

- Coating machinery (1)

- Die casting moulds (1)

- Extrusion - steel and metals (1)

- Fertilizers and soil conditioners (1)

- Finished Metal Products (1)

- Foundries - copper, bronze and brass (1)

- Glass manufacturing - machinery and equipment (1)

- Heat treatment furnaces (1)

- Import-export - chemicals and pharmaceuticals (1)

- Lubricants, graphite (1)

- Nozzles - non-ferrous metal (1)

- Nuts and bolts (1)

- Pipes and tubes - non-ferrous metal (1)

- Rivets (1)