- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling machines

Results for

Milling machines - Import export

METAL IN LTD

Bulgaria

The company have Milling machine with vertical center with 3 and 5 axis with CNC controls. Maximum size of details which we can work is 1200x600x600 mm and maximum weight – 1200 kg. We produce details from all types of steels, crude iron and non-ferrous metals. We possess with instrumental equipment for producing and repairing of devices and instruments, needed for different production of the company. The main details which we produce are: Pneumatic dividers for compressors Тooth wheels Hydraulic distributors Parts and components for mechanical engineering Details and units for the food industry

Request for a quote

EMSIL TECHTRANS SRL

Romania

Our Emtech brand with rotary tables Horizontal Boring & Milling Machines HBM, HBMI, HBMT HBM, HBMI, HBMT

Request for a quote

EMSIL TECHTRANS SRL

Romania

Robust and versatile milling machines

Request for a quote

CAD-CAM ENGINEERING SOLUTION SRL

Romania

Due to 5 axis machining and high speed, very complex parts can be produced.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

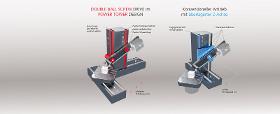

“The deflection (∆) of the tool tip (TCP) due to the machining force (F) depends to the third power ( l 3 ) of the length ( l ) of the distance TCP to the front bearing axis (A), in relation to the bending stiffness (E · I) “ Or: the shorter l , the smaller ∆ and the higher the precision

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Robust, long-lasting machine for individual part and small series production Very good accessibility to the processing unit and to the workpiece clamping Crane loading possible Up to 3 mobile tool rests Service and maintenance-optimized accessibility to all machine components Crane hook machine, therefore short set-up times OUR TBM mono IS THE SPECIALIST FOR INDIVIDUAL PARTS AND SMALL SERIES. SPECIAL FEATURES: VERY SMALL DRILLING DIAMETERS WITH A LARGE DRILLING DEPTH AT THE SAME TIME

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center – year of construction: 2007-2008 Product name: MFZ 2-3 Update Used 3-spindle horizontal 4-axis machining center Year of manufacture: 2007-2008 Painted in RAL1002 (sand yellow) or red-white Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (per machine without coolant system and accessories) X-axis travel: 300 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z axis 60,000 mm/min 3 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) Knoll KSS system with paper belt filter and magnetic separator Flush gun Complete enclosure Tool storage (3 x 30 tools)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used, partially overhauled three-spindle, horizontal machining center Product name: MFZ 2-3 Update Machine number 53152 Used 3-spindle horizontal 4-axis machining center Year of construction: 2009 The machine produced until October 2020 Sinumerik 840D Powerline control X-axis travel: 300 mm Y-axis travel: 500 mm Z axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z-axis 60000mm/min 3 motor milling spindles GMN, version with HSK63 tool holder Drive power (S1 / S6) 28 KW (constant) Torque (S1 / S6) 63/83 Nm Maximum speed 16,000 rpm Chip conveyor Knoll (scraper belt conveyor in the setting across the machine) Knoll coolant system with paper belt filter Flushing gun • Complete housing Tool storage (3 x 30 tools) Operating voltage 400V 3N ~ Control voltage 24V DC

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

DIVERSE TASKS REQUIRE FLEXIBLE MACHINE CONCEPTS, SPECIAL QUESTIONS REQUIRE INDIVIDUAL SOLUTIONS AND EFFICIENT PRODUCTION REQUIRES SECURE PROCESS CHAINS, IN SHORT: TFZ – FIT 2 TASK! With the very successful and established TFZ series, SAMAG has been a guarantee for task-specific solutions and tailor-made machines for years. At the same time, the well-thought-out machine structure of the TFZ enables optimal deep drilling and highly dynamic milling with just one clamping and thus efficiency par excellence. The unique design principle always ensures optimal accessibility, a minimally short distance between the swivel bearing and the processing point and extremely stable tool guidance for high-precision work, even when high lateral forces occur. No matter where you set your priorities in the manufacturing process, we are able to technologically align our TFZ machine accordingly and you can rely on “your” TFZ solution to fit perfectly, today and in the future.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles Clamping device with 6 or 8 workpieces Processing the ends and connections on MFZ Processing of deep hole drilling 4-6 spindling on SAMAG shaft drilling machines

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Complete machining on MFZ including axis drilling 2-spindle solution with independent X, Y and Z axes

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles Tool monitoring for all tools takes place parallel to production time

Request for a quote

KRANAMAX

Bulgaria

Machinery: With a strong emphasis on metal processing, Kranamax Ltd boasts a wide array of machinery to ensure precision and efficiency in the fabrication of metal structures and components

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

OUR MFZ SERIES CANNOT SHAKE ANYTHING SO EASILY. A SOLID FRAME CAST WITH HYDROPOL ® AND THE CLOSED CONSTRUCTION GUARANTEE THE HIGHEST PRECISION THROUGH BEST VIBRATION DAMPING AND TEMPERATURE STABILITY. The new generation of the MFZ is also built on the solid machine bed with Hydropol ® filling. The specially developed composite material improves the stability of machine tool beds. Hydropol ® makes a further step possible in terms of the interaction between energy efficiency and high productivity. ROCK SOLID DESIGN – THE ADVANTAGES OF A ROCK SOLID MACHINE BED OVER STEEL AND CAST CAST FRAME: Closed construction – analyzed and optimized according to FEM Optimal power flow

Request for a quote

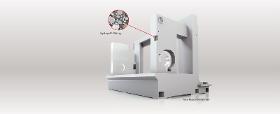

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 22 ensures the precise, cost effective and efficient production of parts. The numerous automation solutions enhance its range of application; individual configuration is easy thanks to the modular design. The Hermle engineers have essentially designed and created this machine with space in mind. With the most efficient footprint possible, the C 22 offers maximum efficiency. And it goes without saying that large components can be machined, too. Nonetheless, the C 22 is ultra compact and ensures the necessary clearance for 5-side/5-axis machining. Short process cycles, quick workflows and the highest possible machine dynamics: The C 22 is designed to machine complex geometries with high accuracy and small tolerances. The circular tool magazine is integrated into the base body of the machining centre and can house up to 65 cutters; additionally, it is possible – as with almost all HERMLE machining centres – to adjust the operating system to the user.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DR. JOHANNES HEIDENHAIN GMBH

Germany

How can you improve manufacturing productivity? Does it make sense to invest in a new milling machine? Are you able to keep track of machine statuses during multiple-machine operation? With its comprehensive machine data acquisition (MDA) and intelligent process analysis capabilities, StateMonitor helps you optimize and bring greater transparency to operational processes. The software displays the production statuses of your machine tools in real time. Extensive notification and evaluation functions help you uncover hidden potential and improve efficiency. You maintain a constant overview that allows you to react swiftly to production disturbances. As a result, you avoid unnecessary downtime and bottlenecks while improving machine utilization and availability. Regardless of where you are, you can even access machine data on your smartphone or tablet. StateMonitor can connect CNCs that use the following protocols: HEIDENHAIN DNC, OPC UA, MTConnect, or Modbus TCP.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

Huron MU5 Universal Milling Machine X stroke: 1300 mm Stroke Y: 700 mm Z stroke: 500 mm Spindle: SA40 Spindle speed: from 30 to 2066 rpm. Table surface: 1630 x 460 mm DRO Speed variator of the feeds Width: 2400 mm Depth: 2200 mm Total height 2300 mm Weight: approx. 4 T Various tooling

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

- made of steel - with safety housing - desktop machine or stand-alone - incl. CNC control Zero3 - incl. ConstruCAM-3D software - incl. Estlcam software - 16 different sizes available

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC milling machining. The material is Pom. The finish is cleaning and deburring.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg offers the highest-quality precision machined mill-turned parts that are engineered to fit your specific application needs. Our CNC mill-turn machining utilizes the latest technology and the highest level of craftsmanship to create parts with the perfect fit and accuracy for any project. What is Mill-Turn Machining? Mill-turn machining is a type of precision CNC machining that uses advanced machines to create a variety of complex parts. The machines used for mill-turn machining combine both milling and turning operations into one setup. Capable of performing multiple simultaneous operations such as drilling, milling, and tapping, mill-turn machining is ideal for parts that require complicated geometries. We Specialize In: Multi-Axis Machining Milling Turning Thread Milling Drilling Tapping Slotting Chamfering Common Applications for Mill-Turned Parts is automotive, medical, aerospace, and food & beverage, etc. Contact us: sales@mxmparts.com

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Basic - the perfect, allrounder machine for the most precise and fastest machining of your sheet materials! Equipped with an FEM optimized machine design, premier precision components, and using powerful Servo Technology, the WiTEC router is capable of achieving top milling speeds and delivering top precision results. Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

AHP PLASTIK MAKINA

Turkey

Different forms of radius notches can be machined according to various Standards.The notches are at different radius and angles. Micrometer notches at 0.01 sensitivity. Continuous machining is possible with electric motors. 1 TS EN ISO 179-1 A type notch knife is given together with the machine. Notch knives for various Standards(optional); ISO 180 Type A, Type B ISO 179 Type A, Type B, Type C

Request for a quoteResults for

Milling machines - Import exportNumber of results

312 ProductsCountries

Company type

Category

- Milling - machine tools (144)

- Milling - steels and metals (30)

- Mechanical engineering - custom work (12)

- Machine tools - metal machining (10)

- Industrial cutting machine tools (9)

- Milling - woodworking machinery (7)

- Moulds, precision (7)

- Flour milling - machinery and equipment (6)

- Flour-milling (5)

- Machine tools, metal machining - parts and accessories (5)

- Food Industry - Machines & Equipment (4)

- Wood sanding machines (4)

- Aluminium alloys (3)

- Forming, rubber - machinery (3)

- Steels and metals - machining (3)

- Testing equipment (3)

- Troughs and feeders (3)

- Measurement - Equipment & Instruments (2)

- Bicycle accessories (2)

- Furniture and decorations, garden (2)