- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mill cutter

Results for

Mill cutter - Import export

URBSCHAT-TOOLS GMBH

Germany

The question of the ideal milling cutter is dependent upon the material to be machined. A single-tooth cutter is often an advantage for ""soft"" materials (PVC, Perspex, Kömacel, etc), wooden materials (chip- or flakeboard) and non-ferrous metals (soft aluminium, Alcubond, etc.), as the problem of cutting erosion in comparison to clogging recedes. A double flute is better suited to very hard plastics and harder types of aluminium (short chipping). Milling cutters with 4 or more flutes are predominantly used to mill metals. SINGLE-TOOTH MILLING CUTTERS Single-tooth milling cutters are mainly used for machining ""soft"" materials. Their extra large chipping space guarantees an ideal chipping removal and high stock removal rate. MULTI-TOOTH MILLING CUTTERS Multi-tooth milling cutters are used for machining ""harder"" materials. Smoother running is achieved, as several cutting edges are always in contact. The more flutes the tool has, the smaller the individual chippings will be.

Request for a quoteHASPA GMBH

Germany

- Solid carbide cutters - Standard - DIN - endmilling cutters, rough-milling cutters, miniature cutters - linearly grooved endmilling cutters - multi cutting machines - cassettes - contour cutters - ball shape, egg shaoe, pointed tree shape, taper shape, tree shape. - cylindrical end cut, flame shape, cylindrical shape, cone shape We help you to find your milling cutters, Please send us your inquiry.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] D-PRO Series is used to cut copper, graphite, and ceramic parts, and is used for general face milling, profile & plunge milling. It is a diamond-coated End mill that is reinforced the wear resistance and enhanced the tool life. [Product Specification] Flat end mill : D0.5 ~ D12 + Various effective length / total length Ball end mill : D0.2 ~ D12 + Various effective length / total length C/R end mill : D2 ~ D12 + Various effective length / total length [Product Model] Flat : 2DRE, 2DPE, 4DPE Ball : 2DRB, 2DPB C/R : 2DRR, 4DRR [Product Use] * D pro series is pure diamond coated Endmill for cutting Graphite, Reinforced plastics, nonferrous metal etc. * Maximized thickness of coating for improvement of wear-resistance * Wide range of effective length and overall length for various work shape.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] A-PRO series is available for cutting general-purpose and variety of workpiece materials such as pre-hardened steel, alloy steel, carbon steel, heat-resistant alloy steel, and reinforced plastic (below HRC 50). It is also suitable for using in shrink fit chucks due to its shape design to prevent the breakage of cutting edge. [Product Specification] Flat end mill : D0.4 ~ D20 + Various effective length / total length Ball end mill : D0.4 ~ D20 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2ARE, 2APE, 2AEL, 4APE, 4AEL, 4APL Ball : 2ARB, 2ASB, 2APB C/R : 2ARR, 2ACR, 2ALR, 4ARR, 4ACR, 4ALR [Product Use] * Suitable for various work materials (HRC below 45), pre-hardened steel, steel, carbon steel, mold steel * Strong wear-resistance and minimizing chipping by adapting A-pro coating * Excellent surface roughness of work pieces due to optimized cutting edge

Request for a quote

HAN SONG M&T

South Korea

·Copper, Graphite and non-ferrous metal ·Special coating to maximize the wear-resistance

Request for a quote

HAN SONG M&T

South Korea

[Product Description] AL-PRO series end mill is optimized to cut Aluminium(AL60, AL 70 line). Various cutting length & total length, customized machining is possible. [Product Specification] Flat end mill : D0.5 ~ D25 (1Flute, 2Flute, 2Flute) [Product Model] Flat : 1ALE, 2ALE, 3ALE [Product Use] * End mills for Aluminum, Alloy, non-ferrous and non-metallic materials

Request for a quote

HAN SONG M&T

South Korea

[Product Description] AL-PRO series end mill is optimized to cut Aluminium(AL60, AL 70 line). Various cutting length & total length, customized machining is possible. [Product Specification] Flat end mill : D0.5 ~ D25 (1Flute, 2Flute, 2Flute) [Product Model] Flat : 1ALE, 2ALE, 3ALE [Product Use] * End mills for Aluminum, Alloy, non-ferrous and non-metallic materials

Request for a quote

HAN SONG M&T

South Korea

[Product Description] S-PRO series is mainly used for cutting difficult-to-cut materials such as stainless, titanium, nickel and hastelloy in the aerospace field. A deep chip evacuation space of the S-PRO helps to cut difficult-to-cut materials, which facilitates chip evacuation and provides excellent surface finish. [Product Specification] Flat end mill : D1 ~ D20 Ball end mill : D3 ~ D20 C/R end mill : D1 ~ D20 [Product Model] Flat : 4SUE, 4SUEA Ball : 4SUB C/R : 4SUR, 4SURA [Product Use] * The cutting edge type of S pro series is unequal flute and it is suitable for cutting difficult to cut materials like alloly steels, stainless steels, Titianium, Inconel etc. * 4SURA, 4SUEA are specialized to cut Inconel. * Strong wear-resistance by adapting S-pro coating.

Request for a quote

TOS KAS KOVOVÝROBA, SPOL. S R.O.

Slovakia

HSS material such as drill bits, milling cutters, screw taps, threaded eyes, radeco, boring machines, circular saws and pieces from them

ROSE PLASTIC AG

Germany

Plastic cases sturdily designed for all-around protection of high-quality milling cutter heads Extremely strong blown double-wall case Secure center fixing screw offers high protection of cutter edge Centering points on base and cover for secure stacking

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

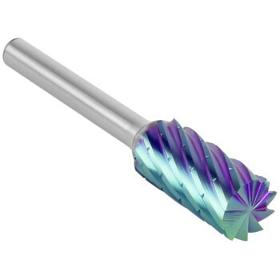

Tyrolit’s tungsten carbide burrs can machine materials like steel, stainless steel, non-ferrous metals, cast iron, and HSS. They come in various shapes and profiles, including tapered, cylindrical, ball-shaped, and special designs for angles, corners, and flutes. The parts are soldered with a copper alloy for impact resistance, enhancing safety and performance. Our burrs ensure first-class grinding with maximum economy, featuring long tool life due to a specially developed cutting edge geometry. The aggressive cutter profile allows for significant material removal in a short time, with reduced heat generation to protect both tool and workpiece, crucial for stainless steel to prevent discoloration. The new HPC-coated tungsten carbide burrs for cast iron, steel, and stainless steel offer higher performance, longer life, and better results. The advanced coating improves chip transport and doubles stock removal, with a distinctive Tyrolit color combination.

Request for a quote

ROSE PLASTIC AG

Germany

Hexagonal telescopic plastic packaging tubes with ratchet length adjustment. Ideal for drills, milling cutters, shank tools, tool holders and tool bits Infinitely variable telescopic length adjustment Speedy efficient packaging Speedy handling

Request for a quote

NORELEM FRANCE

France

Zero backlash, torsionally rigid, resiliently flexible and maintenancefree full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Assembly Recommended shaft tolerances h7. On request Hub bores D1 and D2 with separate tolerance class or range. Note Procedure for enlarging predrilled bores D1/D2 Drill the bore out using a small as possible drill or milling cutter. Use a single point tool to turn or bore the hole out to its finished size. Ensure that the coupling is securely held during the machining process and that the drill feed is not too high. The cut depth should not exceed 0.5 mm and the feed for the single point tool should also be not too high.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Install impact protection For screwing and riveting secutex impact protection with an internal perforated plate can be screwed or riveted in different ways. You can achieve universal impact protection in no time at all. For welding Welding is often the easiest and fastest way of fastening. The various protruding perforated sheet designs allow a very versatile use. For gluing If screwing or welding is not possible, the impact protection can be glued with the secutex special adhesive. Cutting and sawing The secutex material can be sawed with a conventional band saw. The material tries to avoid the cutting tool. Make sure that the wedge angle is as small as possible and adjust the cutting speed if necessary. Milling Use commercially available milling cutters with a small number of teeth. Circumferential speed approx. 200400 m / min, clearance angle ∂ 10 °, clamping angle y 25 °. The use of a drilling emulsion is recommended for cooling and surface optimization. Rotate

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AXINAR SMPC

Greece

Equipped with advanced CNC machinery, including lathes, mills, plasma cutters, rollers, and welders, we have the capabilities to manufacture a wide range of precision metal parts to your exact specifications. With a production capacity of 3000 tons per year, we're well-equipped to handle orders of any scale.

Request for a quote

AXINAR SMPC

Greece

Equipped with advanced CNC machinery, including lathes, mills, plasma cutters, rollers, and welders, we have the capabilities to manufacture a wide range of precision metal parts to your exact specifications. With a production capacity of 3000 tons per year, we're well-equipped to handle orders of any scale.

Request for a quote

MR CO. LTD.

Ukraine

Milling is the process of machining metal with a specific cutting tool, a milling cutter. The milling cutter removes excess material from the workpiece to produce an element of a given shape. Unlike turning, in milling, the workpiece moves forward while the milling cutter rotates. By milling processing, you can obtain a part with a complex shape and geometry from a workpiece. The milling machine is primarily used for demanding tasks such as gear cutting. Our machining workshop is equipped with the most advanced high-tech CNC equipment. We offer our customers full-cycle material processing services, from designing to the protective coating.

Request for a quote

MERCEL, CUTTING KNIVES S.R.O.

Czech Rep.

Our company supplies knives both for the own processing of food, but also for the entire food industry. In addition to the food division itself, knives in the food industry are used, for example, in packaging processing in packaging lines. We also supply food knives in stainless steel. Our product range includes: cutter knives deburring knives filling needles knives for meat mills cutter knives knives for packaging machines band saws

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

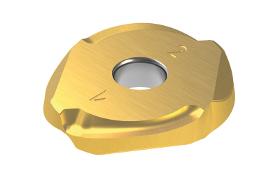

LMT Tools has developed the CopyMax family, specially for the die and mold making industry The latest addition to the family is the one-sided indexable insert CopyMax1. It is an alternative for the reliable CopyMax2 with a two-sided indexable insert. opyMax1 and CopyMax2 prove their advantages above the competition during the roughing and the semi-finishing processes. Both tools are manufactured using the manufacturing process HQS (High Quality Sintering), which is registered for patent approval. For the first time, HQS allows for pressing and sintering a ball nose copy insert complete, resulting in precision sintered cutting edges. In addition to introducing the new indexable insert CopyMax1, LMT Tools has developed new shanks for the CopyMax. A cylindrical steel shank version is available in two different lengths, and the cylindrical bolt-on milling cutter are both new to the program. Both milling systems are designed with internal coolant supply.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Highly versatile: The MultiFace H45 PRO4 and P45 PRO8 face-milling cutters enable high material removal rates even on lower performance machines. This is achieved with the highly positive cutting edge geometry of the MultiFace H45 PRO4, which has four cutting edges per indexable insert, as well as the positive cutting edge geometry of the MultiFace P45 PRO8 with its eight cutting edges. The easy cutting cutters can therefore be used for many different applications.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Carbideline consists of CarbideLine-S solid carbide tools, CarbideLine-H hybrid tools and multi-part carbide tooling with CarbideLine-I indexable carbide tools. All CarbideLine tools excel through maximum productivity in their specific fields of application. CarbideLine-H tools are a new addition to the product range. They cover the module range 5 to 12 and are the 1st. choice for rough machining and finishing large lot sizes, where the tools costs using solid carbide milling cutters are too high and the gear cutting quality is too low using indexable inserts. CarbideLine-H tools are also highly suitable for machining high-strength materials up to 1,400 N/mm2 and enable a gear quality up to quality grade AAA. Its preferred area of application is for gears for commercial vehicles, general mechanical engineering and energy technology. In one specific application it was possible to reduce the gearing costs per wheel by 20% with the CarbideLine-H compared with an indexable insert system.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

The milling cutters used during roughing in die and mold making have to continuously withstand high levels of stress otherwise process reliability and quality cannot be guaranteed. That is why the CopyMax® product family by LMT Kieninger has been specially designed to handle these extreme conditions. The patent-pending HQS (High Quality Sintering) production process and Nanomold Gold high-performance coating ensure high endurance during roughing and semi-finishing. The double-sided CopyMax®2 indexable insert has already convinced many customers with its up to fourfold increase in service life. The single-sided CopyMax®1 insert is now also available. Users can therefore select the appropriate model depending on to the requirements of the respective component. This definitely increases tool life and process reliability while simultaneous reducing handling.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

With the DHC Premium solid carbide end mills, LMT Tools significantly increased the performance of the low-vibration premium tools: 25 % added machining volume is the result of different helix angles in connection with newly developed, stable front cutting edges and peripheral teeth. Additionally, the new cutting material LCPK30M including an innovative PVD high-performance coating contributes to an improved tool life and a safe chip removal. A special performance feature of the DHC Premium end mill (Different Helix Cutter) by LMT Fette consists in its multifunctionality: it allows the user to rough and finish with the same tool. It can also produce narrow projections and up to 2xd-deep slots in steel and cast materials with exceptional surface quality. Advantages: - Increase of the machining volume by 25 % - Increased process reliability due to stable cutting edges - Multifunctional – roughing and finishing with the same tool

Request for a quote

HAN SONG M&T

South Korea

·Copper, Graphite and non-ferrous metal ·Special coating to maximize the wear-resistance

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The millGrind series is specially developed for the requirements of machining in the turbine industry as multiple technology solution in one set-up. The modular machine system in travelling table design allows an individual configuration of the machine according to the customers' needs. Automatic tool and diamond roll changing allows the machining to machine with — Al-oxide, CBN and diamond grinding wheels — Drills — Milling cutter — Laser cladding — Measuring of the unfinished workpiece — Measuring of the machine workpiece including rework in one set-up. This guarantees that all machined surfaces run to each other and errors are avoided by repeated re-chucking. In addition to the machining of new blades and vanes for rework a laser cladding device can be added. This allows the measuring, cladding and grinding or milling of the worn areas.

Request for a quotePOUGET

France

USE : - Drilling Rail on Tracks (or on Site Works) - and Switches and Crossings ADVANTAGES : Steel Tools of High Technical Quality (HSS). Cobalt Steel for Drilling Hard-Grade Steel Rails (900-A and 900-B) Rail Dills in HSS Steel Total Length = 200 mm (2) Morse Taper Shank No. 3 Ø (mm) Twist Milling Cutters in HSS Steel Total Length = 60 mm Inside Drill Ø 7.2 mm 327-18 327-20 327-21 327-22 327-23 327-24 327-25 327-26 327-28 327-30 327-32 327-33 327-34 327-35 18 20 21 22 23 24 25 26 28 30 32 33 34 35 329-18 329-20 329-21 329-22 329-23 329-24 329-25 329-26 329-28 329-30 329-32 - - 329-35 OPTIONS : 1 - HSS COBALT Steel Drills (for Drilling Hard-Grade Rails 900 A and 900-B)- Ref. 328 2 - All of these Diameters are also available, Total Length = 226 mm or 280 mm 3 - Drills with Taper Square Shank (all Ø available) - Ref. 330

Request for a quoteResults for

Mill cutter - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Cutting - machine tools (6)

- Industrial cutting machine tools (5)

- Milling - steels and metals (4)

- Industrial tools (3)

- Blades and knives, industrial (2)

- Metalworking - portable power tools (2)

- Plastic packaging (2)

- Precision engineering - portable power tools (2)

- Shaping - steels and metals (2)

- Stainless steels (2)

- Adjustment - machine tools (1)

- Agricultural machines and accessories (1)

- Blades for saws and cutting machines (1)

- Construction - Machines & Equipment (1)

- Gas turbines (1)

- Gears (1)

- Hand tools, non-power (1)

- Polishing - machine tools (1)

- Polishing equipment and materials (1)

- Steam turbines (1)