- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal industrial presses

Results for

Metal industrial presses - Import export

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Huan-Tai has been a supplier to the aluminum Industry for over 27 years providing dross pans and sow molds to almost every major aluminum producer in our industry. We supply Aluminum dross recycling unit ingot molds dross pans sow molds cooling slat cake black dross.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Aluminum Dross Press Recycling System Capacity: customized

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC laser cutting and bending sheet metal parts for mechanical use

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser Cutting Bending parts

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser Cutting Bending stainless steel parts

Request for a quote

KRANAMAX

Bulgaria

Presses: Our innovative presses are designed for high productivity and precision in metal processing, meeting the strict standards of the industry.

Request for a quote

KRANAMAX

Bulgaria

Presses: Our innovative presses are designed for high productivity and precision in metal processing, meeting the strict standards of the industry.

Request for a quote

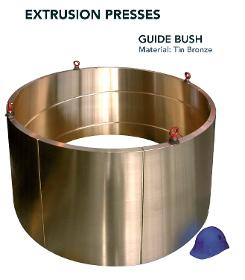

LBI

France

We manufacture rough or fully machined guide bush in tin bronze

Request for a quote

LBI

France

We manufacture rough or fully machined screw nut in high tensile brass, tin bronze

Request for a quote

LBI

France

We manufacture rough or fully machined bush for transverse shaft in tin bronze

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Guarantee the quality of your AM powders with the fully automated Russell AMPro Sieve Station. For more details, please send us a message or click on the website link.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Our press shop has eccentric and hydraulic presses with a capacity range from 30 tons to 500 tons and all sheet metals such as INOX, Aluminum and DKP from 0.5mm to 8mm can be processed in our facilities.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

we provide high precision cnc machining parts customized service process type:miling,turning,Grinding,Tapping,Slotting,Knurling,Bending,Electrical Discharge Machining Wire cutting Machining Part surface treatment:Polishing ,Sandblast,Anodization,blacking,Powder coating,Nickle,chrome ,zinc plate ,passivation. Part material:Aluminium,Brass,Copper,Bronze,Steel,Plastic( PP,PA6,ABS,PMMA,PC,PVC,POM,Bakelite etc.) Magnesium and Titanum

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

good surface stainless steel parts for custom Part name :stainless steel parts part material : stainless steel surface treatment :polishing Tolerance control:0.05-0.1 mm Export rate:98% Price: very good factory made price Engineer software: UG,Pro/e, AutoCAD ,solidwork,edrawing sample orders are welcome

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

CNC turning and autolathe part Xu Feng capable to make the diameter can range from1mm to 300mm and tolerance can reach 0.02mm,part material can be Steel ,Aluminum,copper ,brass ,brozen and plastic etc,we has CNC turning machine & automatic lathe 20 sets to meet client's big demand for short leadtime and fast delivery Our CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production. CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret, with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

material: aluminium alloy surface treatment: sandblasting and anodized, machinining surface process: 5-axis cnc machining tolerance: +/-0.02

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANDRITZ KAISER GMBH

Germany

from 630kN upt to 25.000 kN

Request for a quote

TANAX TRUCKS

Slovakia

Our latest high-quality machine parts, built strong and ready for heavy-duty use, reflect our commitment to top performance. We've collaborated in processing their own weldments, showcasing our ability to deliver reliable and custom solutions for our long-lasting industrial partners, including companies like IMC.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Hydraulic press for deep drawing, forging, forming and cutting process

Request for a quote

ONCEL CNC MAKINE

Turkey

eps press, foam press, EPS STYROFOAM DESIGN PRINTING MACHINE is used at facade in the production of decorative sawn timber, stone appearance, broken brick pattern, etc. We obtain these patterns by pressing the heated mold at high pressure on the product.

Request for a quote

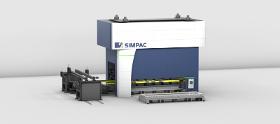

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

Compact presses for a wide range of medium sized parts. Due to its drive-related slide kinematics, the MCL series is particularly suitable for drawn parts. Overview: ● Pressing capacity: 3,000 - 8,000 kN ● Component size: medium ● Slide kinematics: link ● Applications: stamping, drawing, forming Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The Scotch-Yoke drive of the DTL series has a modified link drive characteristic and reduces the slide speed during the forming phase. Thus the presses are not only suitable for cutting, punching and forming tasks, but also for drawing operations. The extra time that the material receives for plastic flow significantly increases the quality of the produced parts. The reduced impact speed of the slide extends the life of the press and the die. Overview: ● Press capacity: 6,000 - 30,000 kN ● Part size: large ● Slide kinematics: link ● Application: as a single press system either as progdie or transfer mode, as well as a press line Description and benefits: ● The outside located pressure points and a long 8-fold slide guiding system well compensate off-center loads, spare press and die and ensure a constant part quality. ● The automatic centralized lubrication system increases pro-ductivity and availability.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The PTS2 series is designed for prototype production, die set-up and modification work (including drawing, bending and punching tasks). The DSP series is especially suitable for die spotting. The mechanical micro inching system provides an accuracy of 0,05 mm. Overview: ● Press capacity: 300-20,000 kN ● Application: die testing tryout and production start-up

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

C-frame presses are flexible solutions for manual work as well as for automated production processes. The CS is the all-rounder among the C-frame presses, while the ECS is ideal for punching and cutting operations with a higher degree of automation. Overview: ● Press capacity: 350-3,000 kN ● Part size: small ● Slide kincematics: crank ● Application: cutting, stamping, bending, embossing Description and benefits: ● Compact design, no foundation work required, good accessibility for maintenance ● Solid, low-stress annealed press body in monobloc design with minimal frame deflection ● Durable, wear-resistant and very quiet hydraulic clutch ● Casting slide with vibration dampening properties (ECS series) ● 4-fold slide guiding for a high tilting rigidity ● Hydraulic overload protection ● Production time as of 12 weeks

Request for a quote

SIMPAC EUROPE GMBH

Germany

Compact and modular presses for a wide range of medium sized parts. Flexible installation options as a single press in progressive or transfer mode or as fully automated press line. Overview: ● Pressing capacity: 3,000 - 10,000 kN ● Component size: medium ● Slide kinematics: crank ● Applications: stamping, cutting, forming, bending, embossing Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The eccentric drive of the DTE series is primarily suited for cutting, blanking, forming and embossing operations. Its characteristic sinusoidal slide motion curve makes it ideal for flat and semi-flat parts. The proven and continuously optimized technology ensures reliable production processes. Overview: ● Type: Eccentric presses ● Press capacity: 8,000 - 25,000 kN ● Part size: large ● Slide kinematics: crank / eccentric motion ● Application: as a single press system either as progdie or transfer mode, as well as a press line Features and benefits: ● High part quality due to rigid, FEM-optimized press design ● The outside located pressure points and a long 8-fold slide guiding system absorbe off-center loads, spare press and die and ensure a constant part quality ● Extensive range of optional equipment, such as die cushions, pneumatic ejectors or moving bolsters for a faster die change

Request for a quoteResults for

Metal industrial presses - Import exportNumber of results

54 ProductsCountries

Company type

Category

- Metal industrial presses (50)

- Presses, hydraulic (9)

- Industrial sheet metal work (2)

- Assemblies, hydraulic (1)

- Bicycle components and parts (1)

- Engraving, industrial - steels and metals (1)

- Machine tools - metal machining (1)

- Mechanical engineering - custom work (1)

- Mechanical surface treatment - machinery (1)

- Metal detectors (1)