- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal folding and bending

Results for

Metal folding and bending - Import export

METAL IN LTD

Bulgaria

Metal In Ltd have two punching machines – TRUMPH and Raskin and two CNC bending machines TRUMPH. This allow us to produce punching details with maximum sizes 1250x2500 mm and maximum thickness 4 mm. Machines are with maximum length 3000 mm and power 120 tones. We also have eccentric presss machines with maximum power of kick 160 tones and hydraulic presses with maximum power 100 tones. We have our own production of punching and bending instruments. The company have three roller bending machines for sheet iron, profiles and tubes. Except upper mentioned operations we also make MIG-MAG and WIG welding, cleaning and powder coating.

Request for a quote

METAL IN LTD

Bulgaria

Bending machines, which we have allows us precise working of tube with maximal outer diameter ф50 mm and thickness of the wall 3 mm. As well we can bend tubes and profiles with big radiuses and big length – 6 m. With our available equipment we produce welded constructions with length till 6 m and weight till 3 tones. This give us a possibility to produce complex products of bended tubes and profiles with excellent quality. The company produce: Constructions, in which is mounted production equipment. Stands for bicycle parking Pumps for pumping out water by hand from big depth Tube knots and details for machines and equipment Tube details for gas device Shelfs Hangers metal fence Shed for reserve players Shed for bicycle parking Metal Cabinets Metal Boxes

Request for a quote

OREMUS S.R.O.

Czech Rep.

The basis of efficient welding process is precision bending on modern machines. In our case, TruBend 8400 Press Brake offers a maximum bending width up to 4000 mm with pressure of a respectable 400 tons.

Request for a quote

ATOM KARINCA LASER

Turkey

With our four-roll cylinder bending machines, we can perform cylinder bending for parts that are 3 meters in length, 150mm to 600 mm in diameter. And maximum thickness is 15 mm.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC laser cutting and bending. The material can be stainless steel or aluminum.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is laser cutting and bending. The material is stainless steel. The finish is cleaning and deburring.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

ESTIMET SP Z O.O.

Poland

We provide sheet metal bending services using three precision Trumpf press brakes (TruBend_3100, TruBend_5085; TruBend_5320) with a maximum pressure of 320 tons and a maximum bending length of 4000 mm. Our well-equipped inventory of bending tools enables us to manufacture even the most complex parts, and dedicated software supporting machine operation allows us to simulate the bending process. All this guarantees the execution of orders with extreme precision and accuracy. In addition, in our machine park we have two CNC bending machines for bending pipes and profiles. We operate on both mandrel and mandrelless benders, while specializing in bending pipes and profiles. In our plant we deal with bending of, among other things: - structural steel - galvanized steel - stainless steel - aluminum

Request for a quote

METAL-TECH

Poland

DIE FOR A PELLET MACHINE, MAKING DIES AND ROLLS CUSTOM

Request for a quote

BASAK LAZER

Turkey

We can shape metal materials with our press brake machine with a capacity of 380 tons. We can shape your aluminum, stainless steel and ST series metal sheets in the desired form.

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

Production of various profiles from sheets of various materials.

Request for a quote

METAL-TECH

Poland

We produce the trapezoidal nuts as customer reauest.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

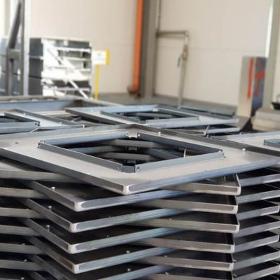

We specialize in manufacturing precise sheet metal components according to customer drawings and specifications, whether in steel, stainless steel, or aluminum. Our commitment to precision is ensured through the use of ACB sensors equipped in our bending and forming machines, allowing us to achieve highly efficient production repeatability. Additionally, we utilize 4 press brakes from TRUMPF company - models 7036, 3066, 5170, and 5085 - which enable us to bend sheets with a maximum width of 4250 mm. However, considering laser cutting capabilities, we bend sheets with a maximum width of 4000 mm, ensuring seamless integration of all production processes.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide the metal profile and pipe bending services. We offer the bending of pipes and profiles from both classical and structural steels of various sizes on machines of a new generation. These machines work with the utmost precision and make it possible to produce almost any shape. Material possibilities: • Pipe processing parameters: - 20 x 1.5 mm (rollable) - 21.3 x 2 mm (rollable) - 33.7 x 2 mm (rollable) - 42.4 x 2 mm (rollable) - 42.4 x 3.2 mm (rollable) - 48.3 x 2 mm - 60.3 x 2 mm • Profile processing parameters: - 40 x 40 x 2 mm - 30 x 30 x 1.5 (rollable) - 40 x 20 x 1.5 (rollable) Is your question more comprehensive or more general? Send us an email at biuro@web-elektron.pl and we will propose the most suitable solution after its processing.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

All of our products are customized by customer's drawing. Please feel free to send us your inquiry.

Request for a quote

VOSSE SP. Z O.O.

Poland

We offer sheet metal bending on a CNC hydraulic press brake with a maximum pressure of 225 tons and a bending length of up to 4000 mm. Thanks to numerical control, we ensure very high repeatability of shapes. Sheet metal bending service is an indispensable process in the metal industry, allowing precise forming and shaping of sheet metal according to individual customer needs. We have a well-equipped warehouse of bending tools allowing us to make even the most complicated elements. Our advanced technology and the experience of our team guarantee the excellent quality of the bending workmanship and quick execution of orders.

Request for a quote

ADMET SP. Z O. O.

Poland

We offer sheet metal bending for all kinds of materials. Maximum width: 3000 mm Maximum thickness: 6mm

Request for a quote

HIRSCH KOVIFLEX D.O.O.

Slovenia

* Bending up to 4000mm in length * 240 tons of power We bend even more complex products and, if necessary, manufacture unique tools. Bending all types of materials and thicknesses. CAD models are used for bending simulation.

Request for a quote

ALLIED FOR TECH

Poland

We offer complete manufacturing solutions based on the customer technical data and requirements.

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

A real eyecatcher - the carriers shoot through the fully transparent tubes and bends in full view. Especially in trade fair stand construction, polymethyl methacrylate offers vast scope for elegant design. Because it‘s halogen-free, PMMA is not only good-looking but also meets the highest fire protection requirements.

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

Safe - fast - easy: these are the key properties of the KURO PEHD underground tube programme. This is the only absolutely watertight underground pneumatic tube that doesn‘t require a forwarding tube because the carriers travel directly in the specially dimensioned system.

Request for a quoteResults for

Metal folding and bending - Import exportNumber of results

51 ProductsCountries

Company type

Category

- Bending - steels and metals (38)

- Folding, bending and welding of rubber and plastic (5)

- Industrial sheet metal work (4)

- Bending machine tools (3)

- Turning - steels and metals (3)

- Finished Metal Products (1)

- Construction, industrial - contractors (1)

- Cutting - steels and metals (1)

- Folding machine tools (1)

- Pipes and tubes, steel (1)

- Steel & Metals (1)