- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- medical parts

Results for

Medical parts - Import export

XUFENG TOOL TECH GROUP LIMITED

China

1.Part material: titanium 2.Machining type: precision cnc turning 3.Surface:Polishing ,Ra0.8 4.Tolerance:+/-0.05mm 5.Application : medical equiment parts 6.Quality,reliability and long product life.

Request for a quote

GDI CORPORATION

Bulgaria

ISO 14644-1 certified cleanroom with class 8 air cleanliness constructed by market-leading air system and cleanroom suppliers. We offer manufacturing of medical plastic bottles/components to packaging without human contact.

Request for a quote

RPWORLD

China

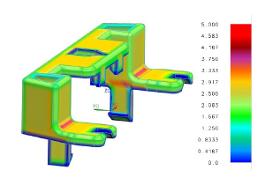

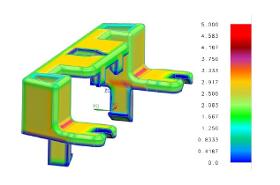

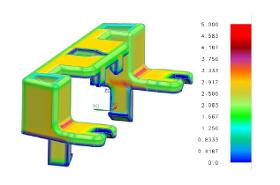

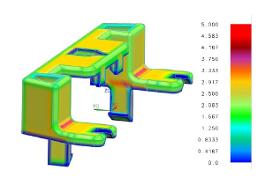

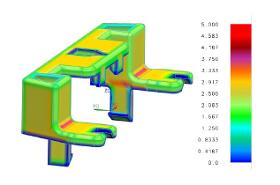

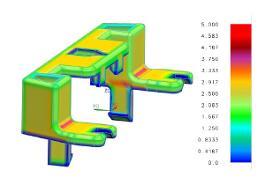

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

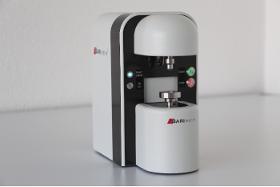

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The BARImeter® is a precision metrology device that offers a great flexibility in the measurement of microtechnical, horological and medical parts. In particular, it is possible to measure small friction torques in both directions of rotation as well as holding torques. Examples: - Barrel measurement - Friction-wheel measurement

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

RPWORLD

China

Is your medical part design right for manufacturing? The in-depth DFM analysis of RPWORLD helps you find the answer. Our experienced engineering experts could make in-depth DFM analysis to optimize parts. - Professional engineering team The professional engineering team have gained extensive experience on design improvement, and is specialized in analyzing the part from the perspective of material selection, manufacturing process, finishing options, and more. - Reduce costly redesign Improving medical part manufacturability to reduce costly reworks. Especially the minor changes could result in the costly reworks on mold and further increase the production cost. - Mitigate design risks Performing comprehensive evaluation to mitigate design risks before production begins. - Accelerate products to market Optimizing design to shorten medical parts development cycle and accelerate products to market.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Hai Tong is one of the leading manufacturer of high-volume, precision metal stampings for OEMs in the medical, automotive and electronics industries. Our skilled workers using in high speed metal stamping process to produces complex stamping parts which are of the highest quality standard and one stop solution for your specific parts. High speed precision stamping is the most cost-effective solution to produce small, tight tolerance but large volume parts, we can work with a variety of materials, such as copper alloys, stainless steel and carbon steels, and spring steel, enriched with years of experience in fabricating electronics metal stamping parts and medical stamping parts leads us to be top manufacturer who have enough knowledge to make the most complex stamping parts with stable quality and on time delivery. When components are produced through high speed stamping, the assembly process is also greatly simplified.

Request for a quote

TAKE CRAFT MUHENDISLIK TICARET VE LIMITED SIRKETI

Turkey

At Take Craft Engineering, we pride ourselves on offering a wide range of production services for metal and plastic products across various sectors. By conducting detailed analyses of projects, we produce high-quality and durable products tailored to our clients' needs. Acessories Metal Accessories: Keychains, belt buckles, bag accessories, and other decorative metal parts. Plastic Accessories: Plastic buckles, clips, buttons, and fashion accessories.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Welcome to EWOQE, your specialist for high-precision plastic injection molded parts for medical technology! We understand the demanding requirements of your industry and deliver customized solutions that meet the highest quality standards. Our experienced team collaborates closely with you to develop the optimal plastic injection molded parts for your medical applications. Utilizing state-of-the-art technologies and high-quality materials, we ensure our products comply with the strictest regulatory requirements and offer the highest precision and reliability. Whether for components of medical devices, laboratory equipment, or consumables, we are your trustworthy partner for all your needs in plastic injection molded parts for medical technology. Rely on EWOQE for top-notch quality, rapid delivery times, and excellent customer service. Contact us today to learn more about our tailored solutions for medical technology and to advance your projects.

Request for a quote

ACKOR MOULD LIMITED

China

We are factory for injection molds and molding products in medical industry.

Request for a quote

WESTLAKE PLASTICS EUROPE

France

With the new tightening procedures for cleaning and disinfecting implant ancillaries, PPSU offers an interesting solution guaranteeing a longer life cycle for products. Though it costs usually more than other medical grade polymers (POM, PP), it can nevertheless prove to be more economical in the long term due to its durability. This is especially true for complex designs which are expensive to machine. PPSU does not have any problems with the cleaning & pre-disinfection products. Our material is lot controlled, serialized and is delivered with a certificate of conformance. Coloured resin has been tested under ISO10993/5/10/11/18. The material is not for permanent implantation. PPSU behaves very well after a large number of sterilisation cycles in an autoclave at 134°C/273°F, it can be sterilized through other methods (ETO; gamma, plasma, dry heat). it is polishable for a perfect finish.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

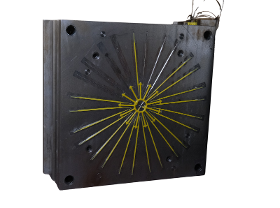

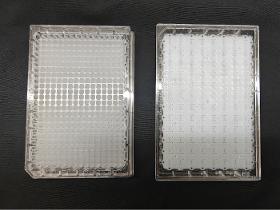

we received an inquiry regarding the custom biological trays, particularly with the unique specification of incorporating 0.1mm diameter pins at the bottom of the tray holes. We appreciate the complexity of this request, as such fine detailing can often lead to the formation of burrs during the injection molding process. To ensure the highest standard of precision and quality, our engineering team has adeptly machined these small pins using Electrical Discharge Machining (EDM). Following this, each pin is carefully polished under a microscope to achieve an immaculate finish. We were excited to move forward with this project and are dedicated to exceeded our client's expectations with our advanced manufacturing techniques and meticulous attention to detail. if you want to learn more details, please do not hesitate to reach out.

Request for a quoteResults for

Medical parts - Import exportNumber of results

46 ProductsCountries

Company type

Category

- Medical Equipment (27)

- Telescopes (20)

- Shirts and blouses (4)

- Laser - cutting and welding machines (2)

- Plastic products for the medical industry (2)

- Automation - systems and equipment (1)

- Bottles and jars, plastic (1)

- Cleaning - steel and metals (1)

- Cleaning machines, industrial (1)

- High-vacuum photo-cells (1)

- Lifts (1)

- Mechanical engineering - custom work (1)

- Medical services - specialised (1)

- Milling - machine tools (1)

- Motor mechanics - hand tools, non power (1)

- Plastics moulding (1)

- Printers - computer (1)

- Shaping - steels and metals (1)

- Stainless steels (1)

- Steels and metals - forming and cutting (1)