- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- media supply

Results for

Media supply - Import export

IGUS® GMBH

Germany

Compact, modular, cost-effective, twistable up to 7,000°* Rotary movements in a very small space - 20 times round its own axis. With the very compact igus twisterband, rotations can be achieved cost-effectively with low wear and very little maintenance, even in confined spaces, whereby energy, data and media can still be supplied reliably. - 7,000°* and more rotational movement horizontally and up to 3,000° in the vertical installation position - Rotary speeds up to 180°/s possible - Compact, modular and light - Strips can be shortened as required - Minimum installation spaces, fits tightly around the rotary axis - Can be used reliably in various installation positions (horizontal, vertical, upside down) - Cost-effective - Easy filling

Request for a quote

IGUS® GMBH

Germany

drylin® Q Square linear guides Square section tube made of hard-anodized aluminum Torque resistant without 2nd guidance Tolerates moments up to 10 Nm drylin® Q square section tube drylin® Q - bearing housing, adjustable Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually drylin® Q - bearing housing drylin® Q - bearing housing, adjustable with hand clamp Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually With manual clamp drylin® Q - bearing housing with manual clamp drylin® Q - housing bearing Q20 enclosed, anodized aluminium housing short design or tandem housing Torque resistant without 2nd guidance drylin® housing bearing Q20 drylin® W - flange bearing Flange pillow block made of anodized aluminum Round flange (01 version), square flange (02 version Standard type or tandem housing Torque resistant without 2nd guidance drylin® W - flange bearing drylin® Q - housing bearing Q10 Solid polymer bearing made of iglidur® J Very light Tolerates moments up to 3 Nm Space saving drylin® Q - housing bearing Q10 drylin® Q - accessory Based on a torque resistant square guide with 7.5 mm edge lengths Hollow chamber for supply lines (media, compressed air,cable) drylin® Q - accessory drylin® Q - gripper axis Toothed, hard-coated and corrosion protected square-hollow profile Move loads up to 500 g at speeds of up to 0.7 m/s Bearing made of iglidur® J Drive: NEMA11 stepper motor with gear wheel drylin® Q - gripper axis Move linear torque resistant, completely lubrication-free. The drylin® Q linear construction kit offers the user maximum flexibility in the design Individual housing options such as solid plastic bearings and adjustable complete housings with and without manual clamp are available. Due to the hollow chamber design, the rugged hard-anodised aluminium profile is very light and is suitable for the simultaneous conducting of supply cables. The mounting options are highly variable, among others, using slot nuts; installation size 20 can also combined with all 20/20 aluminium construction profiles. 1. Profile made of hard-anodized aluminum 2. Main body of the carriage made of aluminum 3. Customized clearance adjustment 4. Cover made of solid plastic 5. Gliding elements in high-performance polymer iglidur® J serve as a guide bearing and guarantee optimum running properties drylin® Q Square linear guides Square section tube made of hard-anodized aluminum Torque resistant without 2nd guidance Tolerates moments up to 10 Nm drylin® Q square section tube drylin® Q - bearing housing, adjustable Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually drylin® Q - bearing housing drylin® Q - bearing housing, adjustable with hand clamp Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually With manual clamp drylin® Q - bearing housing with manual clamp drylin® Q - housing bearing Q20 enclosed, anodized aluminium housing short design or tandem housing Torque resistant without 2nd guidance drylin® housing bearing Q20 drylin® W - flange bearing Flange pillow block made of anodized aluminum Round flange (01 version), square flange (02 version Standard type or tandem housing Torque resistant without 2nd guidance drylin® W - flange bearing drylin® Q - housing bearing Q10 Solid polymer bearing made of iglidur® J Very light Tolerates moments up to 3 Nm Space saving drylin® Q - housing bearing Q10 drylin® Q - accessory Based on a torque resistant square guide with 7.5 mm edge lengths Hollow chamber for supply lines (media, compressed air,cable) drylin® Q - accessory drylin® Q - gripper axis Toothed, hard-coated and corrosion protected square-hollow profile Move loads up to 500 g at speeds of up to 0.7 m/s Bearing made of iglidur® J Drive: NEMA11 stepper motor with gear wheel drylin® Q - gripper axis

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The cartridge emptying ViscoMT-C offers the possibility to empty 180 ml cartridges, 310 ml Euro cartridges and 600 ml or 950 ml cartridges in industrial use. Your advantages: - Plunger without direct air supply - Supply of media to the dispenser(s) - Venting option after cartridge change - electrical "empty" and "almost empty" message Controls: - Pressure sensor for inlet pressure control - Pneumatic pressure reducer for pre-pressure adjustment Application: - for low-viscosity media up to viscous media - Media examples: Silicones, adhesives, resins, greases, color pastes, metal-filled pastes Necessary and optional components: Dispenser suitable for dosing (separate article)

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XS hobbock emptying system offers a modern way of emptying containers.The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from approx. 5 l to 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers - direct dosing as pulsation-free flow rate

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XL drum emptying system offers a modern way of emptying containers. The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - Bridge frame can be driven underneath with drums on pallets - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAMAG MACHINE TOOLS GMBH

Germany

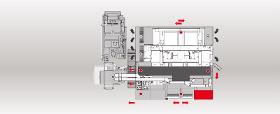

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

Product characteristics of the Disc clutches The shifting clutches mostly serve as a connection that can be activated or disconnected between the power and work units, such as the gear and pump, or in similar installation situations. The disconnection is achieved via the system's existing media supply. (hydraulics, pneumatics) Areas of use of Disc clutches The disc clutches are used in mobile applications, agricultural and forestry machines, sweeping machines and many other areas in mechanical engineering.

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

Specialized systems Our main focus, and our core area of expertise, is developing and designing systems optimized around individual customer requirements. Whether these are process technology, safety-related, or quality assurance criteria – our broad production expertise from draft to assembly provides us with the best possible flexibility. We always consider all peripheral system equipment, such as water and media supply equipment, air supplies and exhaust systems, or specialized testing systems and associated documentation. Our systems are designed to provide the best possible energy and material efficiency.

Request for a quote

ELMOR

Switzerland

Single grain seed weight analyser and seed weight sorter. The elmor SWS opens new possibilities for breeding and quality control of grain, corn, oilseeds, legumes and vegetables. Moreover a variety of applications arise in environmental monitoring. Weight distributions of selected samples (kernels of individual ears, selected generations of breeding programs etc.) are determined in statistically relevant quantities, automatically and unattended. In addition, due to the possibility of sorting, a targeted selection according to the individual kernel weight (seed weight selection / seed mass selection) can be realized. The Seed Weight Sorter (SWS) can be used as seed weight analyser for large amounts of individual kernels. It can run unattended and with high accuracy. In addition, the tested parts can be sorted. As sorting criterion, a weight limit (above / below the limit) or a window value (inside / outside the window) can be selected. The seed weight sorter consists of an C1 counting device that runs in single grain dosing mode. The weight of each individual grain is measured using a high speed high accuracy weigh module for industrial environmental conditions from METTLER TOLEDO. This precision balance has a readability of 10 Milligram, 1 Milligram or 100 Micrograms. The rugged industry scale is largely insensitive to dust, making it suitable for tough continuous operation even in harsh environment. A pneumatic sorting cell transfers the weighted parts according to the measured weight value into one of two bins. The entire process and the storage of all weight values are controlled by a Windows-based PC. The file with all weight data can be exported via XML protocol for further processing with relevant software. Technical data For parts ranging from 2 mm to 10 mm diameter Available resolutions of the scale: 10 mg, 1 mg, 0.1 mg Modes of operation: Serial weight protocolling without sorting Sorting with one predetermined weight limit Sorting according to the moving average Sorting with two limits: inside or outside of a defined range Obtained data when parts are sorted with one limit: Number of weighted particles Weight total Average weight, all particles Particles in the right bin Weight right Average right Percentage right Particles left Weight left Average weight left % left 1000 Grain Weight total 1000 Grain Weight right Time consumption per operation: typically 2 to 4 seconds, depending on the resolution of the scale Operational autonomy The sorter can run unspervised for many hours. It stops when one of the following conditions is true: when a preselected number of parts is weighted when a preselected number is sorted into the right bin when a preselected total weight is processed when a preselected weight is sorted into the right bin when one of the sorting bins is full. System requirements for the control PC: Operating system Windows XP, 7 or 8 .NET Framework 4.5 or higher 2 RS232 or USB Ports Dimensions / weight W x D x H: 390 x 470 x 460mm, 25kg Media Power supply: 230 V, 50 Hz or 120 V, 60 Hz. Other voltages / frequencies on request Pressurised air: dry and clean air, 0.6 MPa (6 bar) elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description Workpiece support Indexing table unit 360x1° / no lifting off NC special indexing table SDV-NC3.5/3H and NC thrust bearing - Duplex-worm gear i=85 with i=5 with belt drive - Division 360x1° - with hydraulic locking, indexing table 1,350 Nm, incl. thrust bearing 2,050 Nm Special charateristics: - 3 channel media supply from below (device tensioning, release, blast air) - Media supply from top, Hirth-ring tensioning, release, sealing air, hydraulic clamping

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Whether lathe or machining center Complete machining made easy: You cannot only use our MANDO and MAXXOS segmented mandrels on the lathe, you can also use them in stationary mode. Simply screw the mandrel onto the ms dock [manually actuated] or hs dock [hydraulically actuated] and you can clamp your workpiece from the inside, stationary mode. Precise, without vibration and with minimum set-up effort. The extremely wear-resistant segmented clamping bushing of case-hardened chromium-nickel-steel with the rubber between the segments, especially developed by HAINBUCH, makes it possible. Hydraulic actuating unit hs dock hs dock is an absolute powerhouse that enables hydraulic implementation of MANDO and MAXXOS segmented mandrels on machining centers. Media supply can be freely selected. It is actuated either from the side or via a base plate from below. Perfect when automation is involved.

Request for a quoteResults for

Media supply - Import exportNumber of results

12 ProductsCountries

Company type