- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- longitudinally welded pipes

Results for

Longitudinally welded pipes - Import export

HS UMFORMTECHNIK GMBH

Germany

The advantages to you: no more deformation of roundness when cutting bends on site easier extension-pipe/tiered pipe bend construction appealing visually pickled surface All of our pipes and pipe bends (both unannealed and annealed) are made of the following material: stainless steel pipe, material no. 1.4301 (AISI 304) longitudinal seam welded pipes hot rolled & cold rolled coils, unannealed, with or without pickling (W1) Make: IltaInox and/or Marcegaglia

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

longitudinal welding with overlap pipe for transporting air and dust. TRANSQuick system is made of galvanised steel sheet, 0.7 and 0.9 mm in thickness. Depending on the wall thickness there are available various lengths 0.7 mm thickness L=500 / 1000 / 1480 mm. 0.9 mm thickness L=500 / 1000 mm

Request for a quote

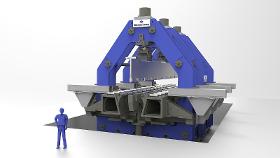

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

pipes (aluminium) - ends cleanly deburred - supplied in trade length of 6 m Ø (mm) FR.038.015.AL 38 x 1.5 FR.040.015.AL 40 x 1.5 FR.045.015.AL 45 x 1.5 FR.050.015.AL 50 x 1.5 FR.050.020.AL 50 x 2.0 FR.054.020.AL 54 x 2.0 FR.060.015.AL 60 x 1.5 FR.060.020.AL 60 x 2.0 FR.065.020.AL 65 x 2.0 FR.070.020.AL 70 x 2.0 FR.076.025.AL 76 x 2.5 FR.080.020.AL 80 x 2.0 FR.090.020.AL 90 x 2.0 FR.100.020.AL 100 x 2.0 FR.108.030.AL 108 x 3.0 FR.114.030.AL 114 x 3.0 pipes (stainless steel) - longitudinal seam-welded pipes - smoothed inner seam - ends cleanly deburred - supplied in trade length of 6 m Ø (mm) FR.038.015.CR 38 x 1.5 FR.040.015.CR 40 x 1.5 FR.045.015.CR 44.5 x 1.5 FR.050.015.CR 50 x 1.5 FR.054.020.CR 54 x 2.0 FR.060.015.CR 60.3 x 1.5 FR.060.020.CR 60 x 2.0 FR.063.015.CR 63.5 x 1.5 FR.065.015.CR 65 x 1.5 FR.070.020.CR 70 x 2.0 FR.076.020.CR 76.1 x 2.0 FR.080.015.CR 80 x 1.5 FR.080.020.CR 80 x 2.0 FR.084.020.CR 84 x 2.0 FR.085.020.CR 85 x 2.0 FR.089.020.CR 88.9 x 2.0 FR.100.015.CR...

Request for a quote

BASE GROUP SP Z O.O.

Poland

We produce constructions for marine, e.g. various systems, machines or tanks. We manufacturing according to international standards for welding processes (ISO 3834-2). Thanks to constant control, rail welded elements comply in 100% with our customers’ project requirements. The range of our products comprises both steel elements made to order of black and stainless steel and aluminium. The production process is based on the PN EN 15085 standard.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

The spiral welded steel pipe is a low-carbon structural steel or a low-alloy structural steel strip, which is wound into a tube blank with a certain helix angle (also called forming angle), and then welded and formed into a pipe joint, which can use a narrow strip. We strongly recommend the use of steel spiral hoses in various construction fields, especially in shaft shafts (ventilation, lift shafts, etc.). The areas of use of spiral pipe and steel spiral pipe are different. Steel spiral pipes are used in cables in areas that may be subjected to loads and impacts.

Request for a quoteResults for

Longitudinally welded pipes - Import exportNumber of results

7 ProductsCountries

Company type