- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- loading machines

Results for

Loading machines - Import export

INAC

Spain

“Machine for loading timber to cutting machine”

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Cable trunking for footfall loading in machining centres PFLITSCH Automobile-Trunking complies with the works standard for many automotive manufacturers and serves as walkable floor trunking in many automated manufacturing lines and robotic production plants, allowing loads of up to 1,200 N and using antislip channelled sheet covering (slip-resistance rating R10). With seven cross sections from 100 mm to 600 mm wide, standard base perforations and universal separating walls, this robust trunking can be placed and combined with other PFLITSCH trunking systems to customer requirements. Your advantages: Walkable floor trunking with high footfall load High strength, wide support spacing Channelled sheet for antislip safety Can be combined with other trunking systems

Request for a quote

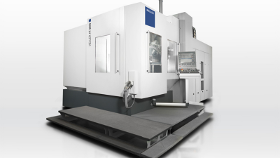

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

ID GROUP

France

ergonomic slabs which maintain worker comfort and which at the same time resist the passage of rolling machines and heavy loads interlocking slabs on 4 sides for flexible arrangement quick installation antifatigue function thanks to its lower surface consisting of «FlexPoints» supports up to 45 tonnes / m² easily separable and reconnectable panels to obtain a new configuration yellow safety angles and ramps available to secure and facilitate access to the slabs by users and rolling machines very good resistance to chemicals

Request for a quote

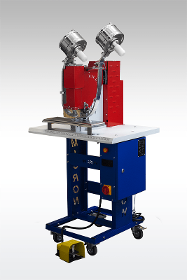

MICRON AMERICA

Turkey

Fully automatic, self loading machine. Fed by hoppers. Punches a hole and sets the grommet in one step. Can only accommodate one size die for the lifetime of the machine. Foot pedal for hand safety. Requires 220 volts of AC power to operate. This machine is built around a newly designed frame that requires less space and is much lighter than previous generations. The M 500 fully automatic machine that feeds both the grommet and washer punches the hole in the material and attaches the grommet and washer, all in a single cycle. This machine has been specifically engineered for light to medium duty applications. Features Flywheel powered and cam actuated to ensure consistent settings. Advanced cutting technology to punch a hole in multi layeredmaterialsCompensator to allow for a nominal variance in material thickness.Stripper plate to lift grommet and washer setting off the pilot ofthe anvil.

Request for a quote

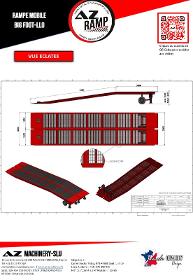

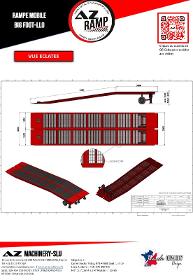

AZ MACHINERY

France

Ideal for military applications, use in breakage, dump, sites requiring the loading / unloading of bulky machines, large machines. Disassembled in two identical mobile and independent parts, this one will allow you to unload all types of machines whatever its width. Its full access platform will allow you easy access to all types of material handling and construction. The two parts of this ramp are usable independently of one another, or together.

Request for a quote

AZ MACHINERY

France

Applications: Ideal for military applications, use in breakage, dump, sites requiring the loading / unloading of bulky machines, large machines. Disassembled in two identical mobile and independent parts, this one will allow you to unload all types of machines whatever its width. Its full access platform will allow you easy access to all types of material handling and construction. The two parts of this ramp are usable independently of one another, or together.

Request for a quote

AZ MACHINERY

France

Ideal for military applications, use in breakage, dump, sites requiring the loading / unloading of bulky machines, large machines. Disassembled in two identical mobile and independent parts, this one will allow you to unload all types of machines whatever its width. Its full access platform will allow you easy access to all types of material handling and construction. The two parts of this ramp are usable independently of one another, or together.

Request for a quote

MINEBEA INTEC GMBH

Germany

Ideal for installation in platform scales and integration into machines: with the BCL-A single point load cell, you rely on proven quality from a leading manufacturer of industrial weighing technology. Suitable for load ranges from 300 g to 4.5 kg and a platform size of up to 300 mm × 300 mm.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automation with direct impact: BARImètre® Automat can absorb 150 barrels per measuring channel (4 channels max). Load your machine, press START and the Automat will do the rest.

Request for a quote

NORELEM FRANCE

France

For high demand hoisting and carrying tasks in safety-relevant areas (machine construction, load handling equipment, lifting tackle). The CE mark is impressed into the ring bolt. F2 permissible load under max. 45° per ring bolt. On request: Certificate of conformity.

Request for a quote

FERPLAST SNC

Italy

CARTON SEALER MACHINE MOD. FP 9070 - DOUBLE DRIVE SYSTEM CONSISTS OF TWO LOWER SIDE BELTS AND TWO UPPER BELTS. Machine suitable for large boxes, the double drive system ensures a regular feed even in presence of high and light boxes. The two heads simultaneously apply a strip of tape taping above and below the box. Ideal for close fixed format boxes (with constant height and width). Structure of the body in painted steel. Movement of boxes happens via two lower dive belts and two upper drive belts, adjustments for the different formats are carried out using flywheels. The machine is equipped with idle rollers 400 mm length for loading and unloading. The machine is equipped with wheels with brake.

Request for a quote

FERPLAST SNC

Italy

CARTON SEALER MACHINE MOD. FP 9037 - UPPER AND LOWER BELTS The two heads simultaneously apply a strip of tape taping above and below the box. Ideal for close fixed format boxes (with constant height and width). Structure of the body in painted steel. Movement of boxes happens via two lower dive belts and two upper drive belts, adjustments for the different formats are carried out using flywheels. The machine is equipped with idle rollers 400 mm length for loading and unloading. The machine is equipped with wheels with brake.

Request for a quote

SAMSYS GMBH

Germany

The mobile robot ER Work from EasyRobotics is a compact robot station which can be used for handling work or CNC assembly. The ER Work is most often used in combination with the ProFeeder Compact. Here the ProFeeder Compact serves as a kind of parts store. In this case the ER Work loads and unloads the machine. Of course, the ER Work can also do its work alone in front of a CNC machine.

Request for a quote

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO/A ROLL for wrapping carriages (roll container), with manual hooking/cutting of the film and automatic wrapping cycle, limit switches adjustable in height to stop reel holder, adjustable limit switches at the base of the reel holder to start wrapping to the desired height, touch panel display with 3 programs winding, truck driving, foot operated mechanical lock, loading ramp for pallet trucks. (Machine CE).

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-EVF economy automatic horizontal piston filler is equipment with 2 or 4 filling heads,the driven system can be air cylinder or a servo motor. Feature 1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machi machines are made of high-quality stainless steel, making them durable and easy to clean.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERPLAST SNC

Italy

The robot stretch wrapping machine model. FP EASY ECO, battery-powered and automatic steering with overrunning side wheel (CE). Turning around the pallet automatically performs the film wrapping or network. Equipped with manual steering for driving forward and backward buttons, traction batteries maintenance-free gel, current transformer 24 V DC - 220 V AC, built-in charger, electric motors, three-phase inverter driving wheel height adjustment, front bumper security.Place the machine near the load to be wrapped Hook the film or the net to the load Select the wrapping program Press the start button The machine rotating around the load makes the winding and stops at end of cycle Cut the film manually Please note that the machine has a driving wheel side wheel to be placed in contact with the load, if the load surface or irregular shape must assess the suitability.

Request for a quote

FERPLAST SNC

Italy

Wrapping Machine Mod. FP 15 SE/T with table cut for loading and unloading with pallet, and safety photocell, photocell height sensing pallet, digital panel with 3 programs winding, inverter for soft start, manual lock/cut of the film and automatic wrapping cycle (machine CE). NOTE: the machine is loaded from the side. When ordering, with a surcharge, it is possible to obtain the modification for the front load. UPON REQUEST WE CAN MAKE WITH WRAPPING MACHINES: Rotary table diameter mm. 1800 (pallets up to 1300x1300 mm)Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the pallet base and press the start button. The table starts to turn, after a few turns, press the coil rise button and hold it. When the coil of film reaches the top of the load stop the machine or press the down button to perform the double winding. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film

Request for a quote

SAMSYS GMBH

Germany

The 3FG15 3 finger gripper is ideal for gripping a wide variety of cylindrical objects. For example, for the feeding of CNC lathes. Due to the design of the gripper, workpieces are automatically centred. This ensures quick readiness for use as well as a strong, stable grip and precise placement. With a payload of up to 15 kg, the 3FG15 competes with larger, bulkier and much less flexible finger grippers. Like all OnRobot grippers, the 3FG15 can be seamlessly integrated into the robot of your choice. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Due to its flexibility and large stroke, the 3 finger gripper is suitable for various applications. For example for the CNC – machine loading . Another possibility of application would be assembly. It is also ideal for packaging and palletising.

Request for a quote

SAMSYS GMBH

Germany

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be easily moved in your production. The ProFeeder Compact is placed separately in front of the machine to be operated. Then an ER Work or an ER Pedestal is positioned in front of the machine. The robot is located on the ER Work / ER Pedestal. The robot now takes workpieces from the ProFeeder Compact and loads and unloads the machine. It then loads the workpieces back into the ProFeeder Compact. This results in advantages for you, such as more space in your production, quick adaptability for different workpieces and a mobile robot cell. Thanks to the simple design of the drawers of the ProFeeder Compact, workpieces of various sizes and lengths can be processed without major changeover work.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine provides maximum economic efficiency at treatment of big batch volumes at high throughput! The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. At any time, this machine is ready for upgrade to automated application, from the automatic loading & deloading of the machine up to a complete full automated feeding & forwarding system. For industry 4.0 demands, the E90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum-only deflashing), suitable for special applications only.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Floor saw blades are a key part of Tyrolit's diamond tool collection, designed to meet specific customer needs. Many feature Tyrolit's pioneering TGD® technology, ensuring even diamond distribution, optimized cooling, and high cutting performance. This results in longer blade life and reduced machine load. Tyrolit floor saw blades cut asphalt, concrete, and expansion joints with ease, and are ideal for precise openings in slabs and other components. Tyrolit floor saw blades offer top performance for efficient work in road construction and building renovation. Designed for different materials and machine outputs, they provide various benefits, including fast cutting feeds, low cutting pressure, and protective segments to prevent premature wear. Key advantages include smooth running, long life, and optimized tool geometry for bevel cutting. Tyrolit products ensure highly efficient floor sawing and bevelling on construction sites.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Roller bearings support and guide rotating or oscillating machine elements such as shafts, axles or wheels and transfer loads between machine components. They provide high precision and low friction and therefore allow high rotation speeds while reducing noise, heat, energy consumption and wear. Roller bearings are cost-effective and replaceable machine elements that generally comply with national or international dimensional standards.

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Employment of personnel ❌ Process complexity Possible applications of the FH-E3020 ✅ Industrial robot applications for components up to 25 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large, flat sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Tube lifter applications

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

The Vibratory Loading Cart is a an optimal solution for feeding the charge to metallurgical furnaces. OVIBRA Loading Carts are machines used in steelworks and metal foundries. The Loading Carts moves between the loading zone, where the batch set is loaded into the tank of the cart, and then it drives to the kiln and the vibrating chute of the cart feeds the charge into the furnace opening in a controlled manner. OVIBRA Loading Carts offer a number of innovative solutions, are reliable, easy to use and always adapted to individual customer conditions. The Loading Cart can be equipped with a fixed or movable cover for the charging zone of the furnace – limiting dusting, gas escape and heat radiation to the environment. Simple but solid construction keeps costs competitive and ensures high reliability – a solid, heavy frame is the basis of the vibrating chute and fixed sides of the loading hopper, which can be equipped with abrasion-resistant and noise-absorbing linings.

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R80 ✅ Industrial robot applications for components up to 2 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities for you. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R15 ✅ Industrial robot applications for components up to 8 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quoteResults for

Loading machines - Import exportNumber of results

139 ProductsCountries

Company type

Category

- Cartoning machinery (14)

- Packing and packaging - machinery and equipment (9)

- Automation - systems and equipment (7)

- Machine tools, metal machining - parts and accessories (6)

- Industrial washing facilities (5)

- Hydraulic equipment (4)

- Robotics (4)

- Adjustment - machine tools (3)

- Industrial robots (3)

- Printing presses (3)

- Road transport - logistical services (3)

- Agriculture - Machines & Equipment (2)

- Bottling and filling - machinery and equipment (2)

- Cylinders, pneumatic (2)

- Machine tools, cutting - parts and accessories (2)

- Testing equipment (2)

- Textile finishing - machinery and equipment (2)

- Anti-vibration supports (1)

- Balancing machines and systems (1)

- Bearings, roller (1)