- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linear motor table

Results for

Linear motor table - Import export

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a linear motor drive high thrust pick & place unit with compact integral X and Zaxes, using IKO CLube Linear Way ML in the table guiding parts. Thanks to the adoption of a system which drives the moving table with a link mechanism, it realizes both higher thrust of the linear motor and weight reduction of the moving parts and reduces tact time. By entering a positioning program, you may set flexible operation patterns and change strokes easily according to the workpiece. IKO Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and electronic parts assembling machines which require a clean environment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

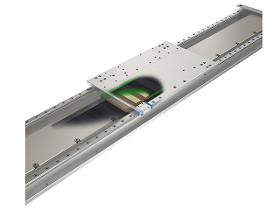

The IKO Linear Motor Table LT is a compact and highprecision positioning table made of aluminum alloy, with an optical linear encoder built in and an AC linear servomotor incorporated between moving table and bed. Three series (Compact Series LT···CE, Long Stroke Series LT···LD and High Thrust Series LT···H) are available and can be selected according to the application. The lightweight moving table and large thrust force of Linear Motor Table LT enables operation with high acceleration/deceleration and high response. Further, the advanced servo technology achieves high static stability and speed stability. Linear Motor Table LT is ideal for applications such as semiconductors and liquid crystal related equipment, measuring instruments, assemblers and conveying machines that require highspeed work.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a moving magnet type linear motor table with a magnet and optical linear encoder scale in the steel moving table part, and a stator coil and optical linear encoder head in the steel bed. For the table guiding parts, an IKO Linear Way, wellestablished in the area of miniature linear motion rolling guides, is used in combination with a linear motor and highresolution linear encoder to realize highly accurate positioning. Thanks to the adoption of highperformance neodymium magnet, large thrust force can be acquired and therefore highspeed and highly responsive positioning is possible, despite its very small body. In addition, high cleanliness is realized as the mechanical contact part is only the linear motion rolling guide thanks to adoption of a landmark driving method without cables. Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a compact linear motor table with excellent functionalities, such as a magnet and optical linear encoder scale in the steel moving table part, and a stator coil and an optical linear encoder head in the steel bed. For the table guiding parts, the adoption of CLube Linear Way ML, which realizes long term maintenance free use, helps reduce the maintenance work. Despite its very small body, the rotator exerts a maximum thrust of 36N by adopting a highperformance neodymium magnet, enabling highspeed, highly responsive positioning. Highcleanliness can be realized as the mechanical contact part is only Linear Way. Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and assemblers which require a clean environment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear is a moving magnet type linear motor table with a magnet and optical linear encoder scale in the steel moving table part, and a stator coil and an optical linear encoder head in the steel bed. For the table guiding parts, an IKO Crossed Roller Way, wellestablished in the area of miniature linear motion rolling guides, is used in combination with a linear motor and highresolution linear encoder to realize highly accurate positioning. Thanks to adoption of a highperformance neodymium magnet, large thrust force can be acquired and therefore highspeed and highly responsive positioning is possible, despite the very small body. In addition, high cleanliness is realized as the mechanical contact part is only the linear motion rolling guide thanks to adoption of a landmark driving method without cables. Nano Linear is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and electronic

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AVM AUTOMATION

France

Positioning table for electric motor Guided by 2 rods on ball bushings (bronze bearings on request) Motor adaptation for linear table These leadscrew tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Trapezoidal screw tables for motor The trapezoidal screw is irreversible and the axial precision of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). The maxi stroke is 750 mm, and any intermediate stroke can be produced. For a XY cross table, the tables are mounted on each other directly by the body with option 308922* (smooth holes are made in the body of a table). For more precise positioning applications, these tables are available with ballscrew.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The ecoLine linear model surface and profile grinding machines are comprised of a single steel base design. The longitudinal linear motor drive table with a max. speed of 60 m/min is its defining characteristic. Since 1999 hundreds of these travelling table machines have been delivered and are well established in the market. The ecoLine model is available with a grinding area of 1,000 / 1,500 / 2,000 x 700 mm. The machine is equipped with linear guides in all three axes. The Y- and Z-axes are driven by servo motors and ball screws (KGT) while the longitudinal X-axis table is powered via direct drive linear motor. The standard 11 kW grinding spindle can be upgraded up to 26 kW. A wide variety of available options like different types of dressing units provide customization capabilities for specific requirements.

Request for a quote

IGUS® GMBH

Germany

drylin® SAW-1040 linear module, drylin® W aluminium profile, surface: hard-anodised, Trapezoidal lead screw TR10x2, machined lead screw end 69x15mm, guide carriage, aluminium shaft end support. Stroke length: 500mm, carriage length: 69mm, NEMA23 stepper motor with JST connector. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

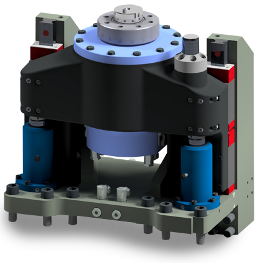

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

PJM MECHANICAL CO.,LTD

China

new design for solar thermal tower power station and high concentrated PV. To meet the mirror panel drive performance, such as the rigidity, position precision, the inside limit switch is developed by POWER JACK MOTION in the patent. It can help customer adjust the angle following customer’s solar tracker. All metal structure design can meet the harshest environments.

Request for a quoteResults for

Linear motor table - Import exportNumber of results

11 ProductsCountries

Company type