- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linear bearings

Results for

Linear bearings - Import export

WIB SA

Switzerland

As the leading manufacturer of linear guide system bearings, WIB works collaboratively with customers on the development of common and tailor designs, supplying the best-in-class technical and commercial solution for each unique application. Each parameter, including environmental factors, precision requirements, speed, temperature, load, boundary dimensions are thoroughly evaluated during the design and development phase.

Request for a quoteLT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Hydrostatic bearings are characterized by practically frictionless movement. The corresponding linear guides are free from stick-slip effects and there is practically no wear on the guides. Gases (mostly air) or liquids (mostly oil) can be used as the carrying medium. Air-bearing guides are ideal, for example, for clean room applications or at high sliding speeds. If oil is used as the carrying medium, higher carrying forces can be achieved with the same size and better damping properties. Various designs are available, which can be customized at any time to meet special requirements in terms of installation space, load capacity, guide length / table diameter, drive type, position measuring system, etc.

Request for a quote

MPS MICRO PRECISION SYSTEMS AG

Switzerland

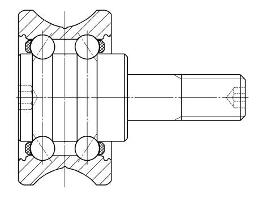

MPS Microsystems offers a wide range of linear bearings that provide smooth movement. Another advantage of these guidance systems: their attractive price. They are available in a range of diameters from Ø 3 mm to Ø 25 mm and are made of injected plastic segments (POM), as well as easy-to-clean stainless steel needles and balls. The needles have three roles: they hold the segments together, they serve as external tracks for the balls, and they define the diameter of the ball bushing. The plastic segments of MPS Microsystems DBL series linear bearings enable their use in environments with high temperature fluctuations.

Request for a quote

MPS MICRO PRECISION SYSTEMS AG

Switzerland

MPS Microsystems is specialized in manufacturing high-precision, miniature linear bearings. We offer a comprehensive range of exceptionally smooth bearings with bore diameters from Ø 2 mm to Ø 6 mm. The balls of these precision bearings meet ‘Grade 3’, the highest quality defined by the ISO 3290/DIN 5401 standard. Combined with a cage and a high precision casing, they allow rapid positioning while reducing friction and eliminating the stick-slip effect. The standard version of MPS Microsystems linear bearings consists of a stainless steel bushing and balls, and a brass cage. An all-stainless steel version or one with ceramic balls can be made on request.

Request for a quote

ROLLON GMBH

Germany

Sturdy and practical linear rails with radial ball bearing sliders. The X-Rail is a family of linear guides with radial ball bearing sliders for applications requiring cost efficiency and high resistance to corrosion. The linear guides with shaped raceways and the linear guides with flat raceways are available in stainless steel or galvanised or nitrided metal sheeting. With the T + U configuration, the X-Rail system can compensate for any axial misalignment in parallelism of the mounting surfaces.

Request for a quote

NORELEM FRANCE

France

Outer jacket stainless steel. Cage stainless steel. Balls stainless steel. Note The linear ball bearings correspond to series 3 of ISO 10285. With doublesided seals and a stainless steel cage. The bearing is secured with DIN 471/472 circlips. Linear ball bearings with doublesided seals should be greased before installation. The specified load ratings apply with the use of hardened and ground shafts.

Request for a quote

NORELEM FRANCE

France

Shell, ballbearing steel. Cage, plastic. Balls, steel. Note With seals both ends. The linear ball bearing is secured using DIN 471 / 472 circlips. Application Suitable for applications where installation space is limited.

Request for a quote

ROLLON GMBH

Germany

Versatile and innovative curved linear guides with radial ball bearing rollers. The curvilinear guides are available in different versions, with constant or variable radius. CURVILINE is ideal for applications such as curved machine housings, door systems in trains or boats, or customized packaging units. Two rail widths: 16mm and 23mm Zinc plated rails and sliders as per ISO 2081 Strokes over 3,000mm Straight and curved paths in one rail Sliders with four rollers, arranged in pairs, maintain the preload over the whole length of the rail Parts as per drawing, customized for each application The Curviline linear guides product family is used for all non-linear motion applications. The linear rails are available in two widths, and made to fit the customer’s design. A single rail can have both curved and straight sections. Main fields of application for Curviline linear guides: Railway Naval Packaging Food & Beverage

Request for a quote

ROLLON GMBH

Germany

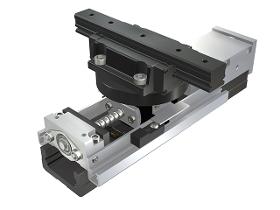

Compact Rail is a linear system consisting of steel linear rails with induction hardened raceways and high precision radial ball bearing sliders, also made of hardened steel. Thanks to their self-aligning capabilities, Compact Rail linear guides simplify the project, improve the performance and reduce the overall cost of application. Compact Rail linear guides are easy to install on all types of surfaces, including non-machined ones. Compact Rail linear guides feature a robust steel slider with ball bearings, self-centering heads with wipers, longitudinal seals to protect the internal components and a top sealing strip. The slider body is accurately finished with matte longitudinal edge chamfer and a shining ground flat surface. The slider heads are equipped with special slow release felt pads and are free to rotate with respect to the slider body, so that the felts are always in contact with the raceways to ensure optimal lubrication.

Request for a quote

ROLLON GMBH

Germany

High load capacity and reduced deflection telescopic rails with caged balls bearings. The telescopic guides have optimal running properties due to inductively hardened raceways. TELESCOPIC RAIL linear slides exhibit little deflection while under very heavy loads, even when fully extended. Telescopic guides come in eight different series (DS, DSE, DSC, DE, DBN, DMS, ASN, DRT) Torsionally rigid intermediate elements with S-shaped, double-T, or squared sections Over-extending, full or partial telescopic strokes are available In the DMS63 Series the supported load can reach 2,000kg per pair. Extremely low deflection and smoothness of movement even in high load, 24/7 applications Some Series can be locked in the closed position Special versions and strokes available upon request The Telescopic Rail product family includes full or partial extraction telescopic rails, and consists of eight (8) different sizes. The deflection resistant central components are available in the S, double T...

Request for a quote

ROLLON GMBH

Germany

Uniline System is a family of pre-assembled linear units boasting a compact size and high speed ensured by the COMPACT RAIL roller bearings, mounted on a self-sustaining extruded aluminum profile. The linear units are driven by a steel reinforced polyurethane belt system. The horizontal seals and the raceway cleaners fitted on both ends of the carriage ensure full protection from dirt. The linear actuator profile is compatible with an endless number of widely available standard fixing accessories. The motor can be connected to the units by means of a full or a hollow shaft Up to 3,000mm strokes Sizes from 40 x 51.5mm up to 100 x 122.5mm Versions available with long sliders and multiple sliders Using linear rails from the COMPACT RAIL family ensures excellent performance in terms of speed and life. The rails in the linear axes of the four product series are laid out in different combinations to meet all application requirements. Using long or multiple sliders increases the...

Request for a quote

ROLLON GMBH

Germany

Sturdy and practical galvanized or stainless steel linear rails with radial ball bearing sliders. The X-Rail is a family of linear guides with radial ball bearing sliders for applications requiring cost efficiency and high resistance to corrosion. The shaped raceway rail, the flat raceway rail and the telescopic rail are available in stainless steel or galvanized sheet metal. With the T + U configuration, the X-Rail system can compensate for any axial misalignment in parallelism of the mounting surfaces. Three rail width sizes: 20mm, 30mm and 45mm Standard rail lengths up to 3,120mm; different lengths upon request Low coefficient of friction Combination of T and U rails for self-aligning bearing applications Easily adjustable slider preload Polymer based wipers available for added roller bearing protection (available on for the thin body style slider) High temperature resistance up to 120°C/250°F The stainless steel X-Rail linear guide version is corrosion resistant, and ensures...

Request for a quote

ROLLON GMBH

Germany

Compact Rail Plus linear guides feature double row ball bearings for higher load capacities and rigid rails with convex raceways and new robust steel sliders with longitudinal protection and floating wipers, Compact Rail Plus has been designed for the most demanding applications in terms of high load capacities, high dynamics and work environment. All while maintaining the self-aligning capabilities that make this product family unique. Sliders are available in four versions: guiding slider (RV); floating slider (RP); extra-floating slider (RU) and rotating slider (RA). Combining two rails with different sliders makes it possible to create self-aligning systems that can compensate misalignment errors on two planes: axial up to 3.5 mm and radial up ±1.3°.

Request for a quote

ROLLON GMBH

Germany

The Easyslide is a system of cold drawn steel linear rails with induction hardened raceways. The linear guides consists of an external 'C' profile linear rail and incorporated caged ball bearings. Five rail widths: 22, 28, 35, 43 and 63mm The sliders inside the linear rails ensure an exceptionally compact system System high load capacity Optimal operation even when shocks and vibrations are experienced Multiple standard lengths available depending on the linear rail section (up to 2,000mm). Special lengths are available on request The Easyslide product family includes compact size linear rails with caged ball bearings, fitted with one or more sliders per rail, to ensure high load capacity and long life. If more than one slider is used in the SN series, they can slide independently inside their own cages, or simultaneously in a single cage. The SNK series features rails with hardened and ground raceways. Variable slider strokes and lengths can be selected. All Easyslide linear...

Request for a quote

ROLLON GMBH

Germany

The PLUS SYSTEM series of linear actuators consists of highly protected linear units featuring a self-sustaining anodized aluminum structure and a steel re-enforced driving belt. This is a line of exceptionally sturdy and high performance actuators in terms of load, moment control, speed and acceleration. High load capacity,High speed,Low wear and tear,Low friction,Low maintenance.Corrosion resistant version All Plus System series of linear actuators are available with stainless steel elements, for applications in harsh environments and/or subject to frequent washes. The Plus System linear units are made by using extruded anodized Anricorodal 6060 and 6082 aluminum, which houses bearings, linear rails, nuts and bolts and components made of low carbon SS AISI 303 and 404C steel, preventing or delaying corrosion caused by humidity experienced in the environments where the linear units are used.The PLUS SYSTEM series consists of 3 distinct products with different features: ELM,Robot,SC.

Request for a quote

IGUS® GMBH

Germany

DryLin® R - Installation videos System selection & service life calculation DryLin® R - Introduction and technical information Special info on DryLin® R linear plain bearing L1 series drylin® igus® test method Liners and pressfit bearings Open and enclosed DryLin® R liners Linear Bearings Open, enclosed, split and self-aligning DryLin® R linear plain bearing Housing bearing Enclosed linear bearing, adjustable, split, in tandem design and as floating bearing DryLin® R housing bearing Flange housing Linear bearing with round or angular flange DryLin® R flange housing Carriage and linear housing Open or enclosed in several long designs DryLin® R carriage and linear housing Shaft end supports and shaft blocks Fixed and moving shaft end supports, shaft blocks in several designs DryLin® R shaft end supports and shaft blocks Shafts and supported shafts Shafts made of aluminum, steel and carbon fiber DryLin® shafts and supported shafts Linear round guide DryLin® R linear plain bearings are based on extremely wear-resistant polymers specially developed for the linear technology. The dimensions are compatible with standard ball bearings. The special geometry guarantees ruggedness even in extreme environments. DryLin® R - Installation videos Advantages: 100 % lubricant-free Dimensionally interchangeable with (recirculating) ball bearings Large variety of choice in housing shapes Shafts, shaft blocks and accessories available from stock 8 different shaft materials Replaceable liners VA stainless steel housing available When not to use it? When little installation space is available drylin® N drylin® W When twist-protection is required for single-axis systems DryLin® T DryLin® N Liners and pressfit bearings Open and enclosed DryLin® R liners Linear Bearings Open, enclosed, split and self-aligning DryLin® R linear plain bearing Housing bearing Enclosed linear bearing, adjustable, split, in tandem design and as floating bearing DryLin® R housing bearing Flange housing Linear bearing with round or angular flange DryLin® R flange housing Carriage and linear housing Open or enclosed in several long designs DryLin® R carriage and linear housing Shaft end supports and shaft blocks Fixed and moving shaft end supports, shaft blocks in several designs DryLin® R shaft end supports and shaft blocks Shafts and supported shafts Shafts made of aluminum, steel and carbon fiber DryLin® shafts and supported shafts

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

IGUS® GMBH

Germany

igubal® rod end bearing, female thread With female thread in metric and inch dimensions igubal® rod end bearing, female thread igubal® rod end bearing, male thread With male thread in metric and inch dimensions igubal® rod end bearing, male thread igubal® rod end bearing CL For simplified mounting, with inner and outer threads in metric dimensions igubal® rod end bearing CL igubal® rod End Bearing CL DT For simplified installation, detectable with female thread in metric dimensions igubal® rod End Bearing CL DT igubal® fitting screw, mm Fitting screw with circlip igubal® fitting screw, mm When to use it? When you want to save weight When rotating, oscillating and linear movements should be implemented When high-frequency oscillations/vibrations predominate When a low-noise operation is desired When an electrically insulating part is required When freedom from corrosion is desired For combinations with pneumatic cylinders and gas struts When chemical resistance is required When high stiffening is required When not to use? When you have temperatures above +80°C (then HT options) When rotation speeds in excess of 0.5 m/s should be implemented When very high tensile and lateral loads prevail When applications should be implemented with hydraulic cylinder When dimensions over 30 mm are needed igubal® rod end bearing, female thread With female thread in metric and inch dimensions igubal® rod end bearing, female thread igubal® rod end bearing, male thread With male thread in metric and inch dimensions igubal® rod end bearing, male thread igubal® rod end bearing CL For simplified mounting, with inner and outer threads in metric dimensions igubal® rod end bearing CL igubal® rod End Bearing CL DT For simplified installation, detectable with female thread in metric dimensions igubal® rod End Bearing CL DT igubal® fitting screw, mm Fitting screw with circlip igubal® fitting screw, mm Special properties of the igubal® rod end bearings Maintenance-free, self lubricating High stiffening Very high fatigue strength in varying loads Compensation for alignment errors Compensation of edge loads Insensitive to dirt, dust and lint balls Resistant to corrosion and chemicals High dampening qualities Suitable for rotary, oscillating and linear movements Very low weight Dimensional series K and E, dimensions according to DIN ISO 12240 Version with metal sleeve in the spherical ball for enhanced torque Tolerances igubal rod end bearings can be used, according to the application, with different tolerances. They are designed with a large clearance in the standard product, which enables a secure operation even under high peripheral speeds. The bore of the inner ring has a tolerance according to E10. The shafts should have a tolerance between h6 and h9. Please contact us in case you require lower or more bearing tolerances. Loads igubal® rod end bearings take high forces in normal ambient temperatures, have excellent dampening properties and weigh only a fifth of the conventional metallic bearing housing. In particular cases the load carrying capacity of the rod end bearings should be checked in a practical trial especially with high constant loads and at higher temperatures. Coefficients of surface friction and speeds Rotary motions of the mounted shaft take place directly in the bearing ball made of iglidur® W300. The advantage of this plastic/steel plain bearing is that high speeds can be achieved in dry operation. Taking the radial loads into account, maximum surface speeds up to 0.5 m/s rotating can be attained. The maintenance-free igubal® rod end bearings casually permit linear and oscillating movements of the shaft. Delivery program igubal® rod end bearings are available in the dimensional series K and E for shaft diameters of 2 to 30 mm in all dimensions according to DIN ISO 12240, and of course respectively in the Form A - with male thread and Form B - with female thread The dimensional series K and partly E are moreover available in inch dimensions and – as special version – with a stainless steel sleeve in the spherical ball. Thereby an essentially higher tightening torque is possible than with the plastic spherical ball. Please ask us for other sizes. igubal® rod end bearings - Applications igubal® rod end bearings - Applications Temperatures Dimensional series K in A+B variants for temperatures upt to +200°C (HAT material).

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

The IKO Alignment Module AM is a positioning module developed for alignment stages by combining high rigidity Crossed Roller Bearings and Linear Way E with Precision Positioning Table TU. Alignment stages can be configured without adjusting the height of each alignment module, since the height tolerance is managed with high accuracy of ±10 μm.

Request for a quote

NORELEM FRANCE

France

Housing anodised aluminium. Bearing surface Frelon (Teflon plus proprietary fillers). Virtually chemically inert. Selflubricating (no additional lubrication required). High temperature range (240 °C to +260 °C). Dampens vibrations. High static load capacity projected surface area x P (P = 1034 N/cm²) Suitable for food, pharmaceutical, medical and chemical applications. Insensitive to dirt.

Request for a quote

MOOG GAT GMBH

Germany

Rotoguide: Micro-jet technology with air bearings from ROTOGUIDE stands for ultimate accuracy, load-bearing capacity and robustness. Shafts and bearing parts are machined to ultra-high precision for a positioning accuracy within µm range. ROTOGUIDE units are especially suitable for highly accurate linear and rotational motion under ultra-high vacuum and for all processes with ultimate demands in terms of cleanliness and accuracy

Request for a quote

FRANKE GMBH

Germany

For our bearing assemblies and linear systems, we use high-quality lubricants as standard that are suitable for most applications. Special operating conditions require special lubricants. Standard and special greases are available in the respective container sizes from us as accessories. They can be used when our bearing elements are used for the first time or for relubricating slewing rings.

Request for a quote

FRANKE GMBH

Germany

Cassette with star grip - standard Cassette with star grip or clamping lever for locking at any position on the guide track. The clamping acts without force on the guide system. It is used for manually movable devices, clamping and holding stops, delivery of tools and processing parts. Please consult us for further information. Cassette with clamp lever Cassettes with clamping levers allow the cassettes to be locked in any position along the guideway. The clamping acts without force on the guide system. It is used for manually movable devices, clamping and holding stops, delivery of tools and processing parts. We would be happy to advise you on application and design.

Request for a quote

NORELEM FRANCE

France

Housing steel. Cage plastic. Balls steel. Note The linear ball bearings correspond to series 3 of ISO 10285. With doublesided seal. The linear ball bearings have a plastic cage which results in quiet and outstanding running properties. With flange for direct mounting on the housing. Linear ball bearings with doublesided seal should be greased before installation. The specified load ratings apply with the use of hardened and ground shafts. Precision guide shafts 21595. Fastening screws 07160.

Request for a quote

NORELEM FRANCE

France

Housing steel. Cage plastic. Balls steel. Note The linear ball bearings correspond to series 3 of ISO 10285. With doublesided seal. The linear ball bearings have a plastic cage which results in quiet and outstanding running properties. With flange for direct mounting on the housing. Linear ball bearings with doublesided seal should be greased before installation. The specified load ratings apply with the use of hardened and ground shafts. Precision guide shafts 21595. Fastening screws 07160.

Request for a quote

GSW SCHWABE AG

Germany

Instead of mounting one or more Transporters to each die, the PSKS features one unit only – mounted directly to the face of the bolster. A heightadjustable mounting bracket allows flexible usage with multiple tools and dies. The only extra thing needed will be scrap trays in different sizes On the left and right end of the system, heightadjustable brackets with linear bearings support a crossmounted aluminum profile. The profile is fastened with standardized clamping brackets and will transfer the motion over the whole width Numerous trays can be mounted. Two rugged nylon Ushape clamps are permanently fastened to each of the trays. The fasteners are designed to slide and fit snug onto the aluminum profile so that exchanging of trays is just a matter of seconds. The length and width of the tray is determined by the size of the die slot.

Request for a quote

NORELEM FRANCE

France

The readytoinstall compact linear housing consists of extruded aluminium housing, installed linear ball bearing 2151102 and doublesided seal. Recommended shaft tolerance h6. Load rating according to specification of the linear ball bearing. With lubrication hole M8x1. Accessory Precision guide shafts 21595. Fastening screws 07160.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quoteResults for

Linear bearings - Import exportNumber of results

65 ProductsCompany type

Category

- Internal transport systems (9)

- Bearings - ball, needle and roller (6)

- Clamp collars, plastic (4)

- Bearings, ball (3)

- Milling - steels and metals (2)

- Silicones (2)

- Brick-making - machinery and equipment (1)

- Chains (1)

- Concrete blocks (1)

- Concrete mixers (1)

- Cutting - machine tools (1)

- Fastening devices - machines for production (1)

- Machine tools, metal shaping - parts and accessories (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Mechanical transmission - components (1)

- Mechanical transmission systems and components (1)

- Pneumatic systems and tools (1)

- Screw cutting - steels and metals (1)