- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lifting solution

Results for

Lifting solution - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Goods Only Lift with no pit requirement- SHERPA Efficient vertical transport of your goods The SHERPA goods only lift is our real all-rounder. It is an efficient and simple to plan solution for vertical transportation of goods in an industrial environment. In its standard configuration, the SHERPA has a load capacity of up to 3,000 kilograms and a lifting height of up to 18 meters (with two to six stopping points). The lift is delivered as a free-standing structure with sheet metal cladding. The required pit depth is very small and can be altogether avoided by choosing the ramp option. No building modifications are required. The lift can be easily integrated into existing building and rack systems. Thus, the installation is fast and easy. This goods only lift is a tailor-made lift. We work closely with our customers, extend our flexibility to design and offer fully customized cabin sizes.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Goods lift for moving goods and passengers safely and efficiently Multi-passenger transport with ESCORTA - special option only from Lödige The ESCORTA goods lift is the ideal solution for easy vertical transportation in multi-level storage and production facilities. Thanks to its new certification (European Machinery Directive 2006/42/EG and DIN EN 81-41) multiple persons can now simply ride in the lift with their goods to the desired floor. This upgrade option ease the flow of goods and people, increases the level of comfort, making transporting goods between levels much easier and more pleasant. In its standard configuration, it has a load capacity of up to 3,000 kilograms and a lifting height of up to 18 meters (with two to six stopping points). The ESCORTA lift can be individually configured in great detail in terms of size, lifting height, materials and look. Cabin dimensions can vary greatly, with length, width and height each reaching nearly three meters.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Lifting height up to 1,800 mm Load capacity up to 6000 kg The lifting tables in the Middle Class are available in any preferred size. Thanks to the modular design (base frame, scissor arms, hydraulic unit, platform sizes and options) they can be easily adapted to individual needs, taking into consideration also characteristics of loading/unloading areas. Benefits Infinitely variable hydraulic height adjustment Extensive project know-how Production according to German quality standards

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Specially designed for lifting cars The PEGASOS garage car lift is a perfect solution for construction projects with limited space. It was specifically designed for lifting and lowering of cars and is based on a sophisticated design and a series of convenient features. It has the appearance of a garage and is the ideal alternative to a conventional ramp. The car lift brings vehicle and occupant automatically to the garage or parking deck. The PEGASOS can be mounted directly on the floor and therefore requires no pit. The platform can be equipped with a comfortable cabin or just a simple railing. Due to its compact design and the elimination of the machine room, it is easy to plan. The lifting function is realized by using a very silent and efficient electric motor. The transport of persons in the car is available upon request.

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Demag rope hoists feature high handling rates, cost-effective operation and maximum safety. As basic hoist units for integration into plant and machinery or as lifting solutions with electronic controls that are optimized for crane applications, with our wide range of rope hoists we offer the optimum solution to meet our customers' specific requirements for efficiently lifting loads weighing up to 100 tonnes.

Request for a quote

HOVMAND A/S

Denmark

When it comes to handling large and heavy paper, cardboard and plastic reels, COMPACT is the right choice. The smallest battery-operated lifter on the market features a combined boom with wheel for easy lifting of rolls up to 100 kg and a rotating V-block for special reels with axle up to 60 kg. A cost-effective alternative for those who like to keep things simple. This ensures your reels are transported safely from A to B – and all the way to the packaging machine (perhaps better: further processing machine?). Our COMPACT lifter is a simple, self-explanatory lifting solution, specially developed for the printing and packaging industry. And it’s so simple: pick up the reel on the boom or the V-block, run to the machine, apply the brakes and then comfortably push the roll from the boom or V-block into the machine.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In addition to the typical lift platform applications, LAWECO offers individual solutions for special lifting requirements. From material lifting systems for high-rise construction to freight traffic and transportation or lorry lifting platforms, LAWECO develops solutions for everything that needs to be lifted. The following designs chosen as examples reveal what is possible when combining creative engineering with experience of a harmoniously cooperating team.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. To handle air cargo container or pallets including adjustable driven ram protection, walkways, a winch and hydraulic side-shift function. Dimension: 830 x 4230 mm Operating stroke: 1200 mmm Rated load: 14000 kg

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. Electrically driven in a store lane as support for ETV. Usable for 10 or 20 feet operation. Dimension: 8966 x 2540 (+1200) mm Operating stroke: 800 mmm Rated load: 14000 kg

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. 10 feet workstation incl. load cells and fixed stops in front of the running rollers. Used to pack or unpack aircargon container or pallets. Dimension: 3200 x 2200 mm Operating stroke: 2100 mmm Rated load: 7000 kg

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

The complete lifting solution we designed for inside a tunnel boring machine (TBM) consists of two vacuum lifters. The first vacuum lifter transports the tunnel segments and keystones to the segment feeder of the erector. To meet the erector’s position the suction pad is able to rotate 90 degrees during the transport. Vacuum lifter as part of the erector The second vacuum lifter operates as part of the erector and perfectly matches the interface of the TBM. To meet every required position the lifter is able to turn 360 degrees.

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

Aerolift designs custom made precast concrete lifting solutions for many situations. During production, storage, internal transport, storage, transhipment, and construction. Precast concrete elements are ideally suited for lifting by vacuum technology. Vacuum lifting technology offers unique benefits compared to other concrete lifting methods. Demoulding of concrete without damage Thanks to the unique properties of vacuum handling, it is possible to demould, lift and turn precast concrete products all in one operation. Moreover, no embedded hoist facilities are required, and the surface is not deformed in any way. The load remains fully intact, without disassembling or destroying the mould. Also, due to the divided surface pressure of a suction pad the curing time of the precast concrete before demoulding is considerably shortened. Instead of at least 24 hours, demoulding is possible after 8 till 10 hours! After removing the concrete product from the mould

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

The Aerolift pipe lifting solutions are applied for many different situations and places. During production, storage, transhipment, and internal transport. For this specific situation we designed a lifting solution to handle bare and coated pipes aboard the ship. The ship, The Amazon, was converted to an ultra-deepwater J-Lay vessel. Our vacuum lifting devices are installed on 4 cargo hold cranes. In tandem mode the cranes will be used to load and unload 24-meter-long pipes in a cargo. The lifting devices are designed to limit deflection of double joint pipes or to handle the entire pipe by vacuum only.

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

The wind energy industry requires precise lifting solutions in many different situations, during production, transport, and construction. All parts of the windmill need handling at one point. The parts have considerable dimensions and must be lifted with care to avoid damage. We offer unique lifting solutions that are an excellent fit for the wind energy industry. All our lifting solutions are unique and designed for a specific situation. Our equipment is used to lift the steel plates of the windmill tower, to lift and turn the spare cabs of the windmill blades, to laminate the windmill blades, to demould prefabricated blades and to lift the long windmill blades itself. Effortless and precise lifting by vacuum handling Aerolift is known worldwide for its customised (vacuum) lifting solutions. Most of our lifting solutions are based on vacuum lifting technology due to many advantages compared to other lifting methods.

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

During the Nord Stream 2 project several Aerolift lifting solutions were used on multiple locations. It is world’s largest pipeline project. During the project, a pipeline is laid through the Baltic Sea, which will transport natural gas over 1,200 km. From the world’s largest gas reserves in Russia via the most efficient route to consumers in Europe. Over 200.000 pipe segments needed to be handled. Almost all handling movements are carried out by an Aerolift lifting solution!

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

Looking for handling equipment for your pipeline project? Use the Aerolift pipe handling equipment. Our custom-made lifting solutions are used for every part of the lifting process of line pipes. During production, storage, internal transport, transhipment, construction of the pipelines and even offshore. Improve the safe work environment Pipe lifting is often done by slings or hooks. Both methods which require manual attachment and detachment. This is no problem on ground level, but what if the line pipes are stacked up to several meters high? Someone must climb the stack, which is a very dangerous situation with great risk to life and limb. All Aerolift pipe handling equipment is designed to rule out this risk. Improving the safety of the work environment tremendously. However, this is not the only benefit. Most Aerolift lifting solutions are based on vacuum lifting technology. In our opining is vacuum handling the best lifting method there is.

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

Handling tunnel segments by vacuum technology. Aerolift designs customised lifting solutions for the complete handling process of precast tunnel segments. The lifting solutions are used during production, transhipment and in the tunnel boring machine (TBM). The unique features of vacuum handling are highly suitable to handle concrete products, such as tunnel segments. Why choose vacuum handling Specially for concrete products, vacuum offers many interesting advantages compared to other lifting methods: Demoulding after 8 to 10 hours Demoulding, lifting, and turning by one lifting device Efficient during handling and the use of storage space No damage or deformation to the tunnel segment Less chance of cracks in the concrete Easy and fast handling Reuse of the same mould Reduced chance of accidents, because no one has to be near the load before, during or after handling Very safe due to the high safety standards of vacuum handling Handling tunnel segments during production

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

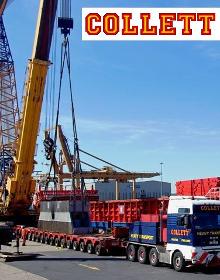

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Collett Heavy Lift Engineers and Appointed Persons (APs) deliver bespoke lifting solutions for your cargo. Our in-house Appointed Persons, Slingers, Banksmen and Crane Supervisors can provide mobile crane solutions, including telescopic mobiles to up 1,000 Tonnes and crawler cranes up to 2,000 Tonnes. We plan, order and supervise all mobile cranes needed, from simple single and multiple lifts, up to complex tandem operations. Our Heavy Lift Team have the knowledge and experience of all aspects of lifting operations allowing us to carry out these tasks adhering to BS7121 Safe Use of Cranes Code of Practice. This allows us to propose, engineer and deliver lifting solutions tailored specifically to each individual project. Our Team of engineers will assume the responsibility for all heavy lift operations, preparing plans, studies, risk assessments, method statements and providing the required insurance where agreed.

Request for a quote

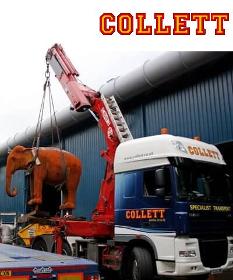

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Crane vehicles and lorry loaders are an essential part of our general haulage operations providing our customers with a flexible delivery solution. Our heavy lift crane vehicle & lorry loader haulage fleet features front and rear mounted cranes with lifting capacities ranging from 9 Tonne/Metre to 205 Tonne/Metre. These vehicles all meet BS7121 Part 4 regulations. All our Crane Vehicle Operators are trained and certified, ensuring maximum safety when undertaking your lifting requirements. Our ALLMI (Association of Lorry Loader Manufacturers and Importers) Certified Drivers are experienced and skilled to self-load and unload freight and machinery. This allow us to safely and efficiently undertake transport, haulage and lifting & positioning tasks without the need for hiring mobile cranes or fork trucks.

Request for a quote

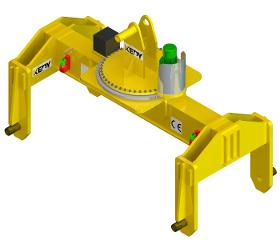

KEDY

Turkey

The KEDY K10300 Rotating Spreader Beam is the ultimate lifting solution for any heavy-duty project. With a maximum capacity of 100 tons, this spreader beam is built to handle even the heaviest of loads with ease. The ability to rotate the spreader beam around a vertical axis gives you maximum versatility, allowing you to move the load in different directions and orientations. The K10300 is equipped with multiple rigging points, allowing you to attach slings or other rigging equipment at different points on the beam. This ensures that your load is properly balanced and supported, providing maximum safety for you and your team. Safety is our top priority, the K10300 is designed with safety mechanisms that prevent the load from rotating in an uncontrolled way, ensuring the safety of the operator and the people around. Choose the KEDY K10300 Rotating Spreader Beam for your next project, and experience the ultimate in lifting power and versatility!

Request for a quote

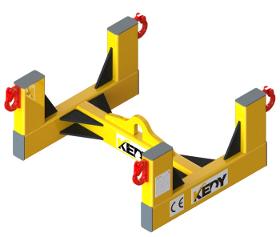

KEDY

Turkey

Introducing the KEDY K1000 Spreader Beam– the ultimate heavy-duty lifting solution for your industrial needs. With a maximum capacity of 100 tons, this product is designed to handle even the heaviest loads with ease. The K1000 is constructed from high-strength steel, ensuring durability and reliability in even the toughest working environments. The innovative design of the K1000 allows for easy and precise load control, making it perfect for use in field. The K1000 also features an adjustable width, allowing it to accommodate a wide range of loads. The traverse feature of the K1000 provides unparalleled stability, ensuring that the load remains balanced and secure during the lift. At KEDY, we understand the importance of safety in industrial operations. That's why we've designed the K1000 to meet and exceed industry standards, ensuring that your lift is always safe and secure. Invest in the KEDY K1000 Spreader Beam for your next heavy-duty lift NOW!

Request for a quote

KEDY

Turkey

Introducing the KEDY K1300 Big Bag Lifting Beam, the ultimate solution for handling and moving large bulk materials with ease and efficiency! Our KEDY K1300 is specifically designed to handle big bags, the most common and cost-effective containers for storing and transporting dry bulk materials such as grain, sand, and fertilizer. The beam's sturdy frame and secure hooks make it easy to lift and move big bags safely and efficiently, reducing the risk of spills, damage to the bag, or injury to workers. One of the key benefits of the KEDY K1300 is its versatility. It can be used with a wide range of big bag sizes and can be attached to any crane or lifting equipment, making it ideal for use in a variety of industries and applications. So if you're looking for a reliable and efficient solution for handling and moving large bulk materials, look no further than the KEDY K1300 Big Bag Lifting Beam! Order now and start enjoying the benefits of hassle-free big bag handling.

Request for a quote

KEDY

Turkey

Introducing the KEDY K4500 Coil Lifting Tongs, the ultimate solution for handling heavy coils with ease. Engineered to provide maximum strength and stability, our tongs are made of durable materials that can withstand heavy use, ensuring long-lasting performance and reliability. The unique jaw design securely grips the coil, preventing slippage and ensuring a secure hold. The tongs also have adjustable jaws to accommodate coils of different sizes, making it a versatile tool for various industrial applications. In addition, the ergonomic handle design provides a comfortable grip, reducing fatigue and increasing safety during extended use. Don't let heavy coils slow down your production process. Trust the KEDY K4500 Coil Lifting Tongs to handle the heavy lifting for you. Order yours today and experience the difference it makes in your operations.

Request for a quote

KEDY

Turkey

Introducing the KEDY K25000 Bale Lifting Grab, the ultimate solution for lifting and transporting bales of hay, straw, cotton, and other materials. Whether you're in agriculture or material handling, the KEDY K25000 makes your job easier, faster, and more efficient. With its powerful hydraulic mechanism and two sturdy arms, this bale grab provides a secure and reliable grip on your bales, allowing you to transport them with ease and confidence. Its durable construction and versatile design make it suitable for a wide range of applications and can be used with a variety of lifting equipment. Trust the KEDY K25000 to handle all your bale lifting needs with ease and efficiency. Get your hands on this exceptional product today!

Request for a quote

KEDY

Turkey

Introducing the K4400 Mechanic Coil Lifting Tong - the cost-effective solution for handling large coils of material. With 20-ton capacity, max width & diameter of 2200mm, it's perfect for manufacturing & construction. No power required, easy to use & handle. Durable design, reliable performance & easy maneuverability. Save cost with KEDY's K4400, a cheaper alternative to electric coil tongs without compromising on performance. Equipped with advanced features that can be adjusted to lift and move coils with precision and ease. Our tong is designed to ensure safety, efficiency and productivity. The ergonomic design of the handle and lever makes it comfortable to use, reducing operator fatigue, and improving overall productivity. Trust KEDY to provide you with a high-quality, reliable, and cost-effective solution for your material handling needs. Order now and experience the difference.

Request for a quote

KEDY

Turkey

Introducing the KEDY K10100 Roll Mill Lifting Equipment, the perfect solution for your heavy-duty rolling mill operations. Designed with the latest technology and manufactured from high-strength materials, the K10100 is built to last and deliver outstanding performance. With its impressive load capacity, you can rest assured that your work roll will be safely and securely lifted and positioned every time. The K10100's size and shape are carefully crafted to fit your specific rolling mill design, ensuring a seamless integration into your operations. The surface finish of the K10100 is of the highest quality, providing durability and protection against corrosion and wear. Its connection points, such as hooks and lifting eyes, make it easy to attach and position your work roll, while its safety features, such as locking mechanisms and safety straps, ensure the safe and secure handling of your equipment.

Request for a quote

LAUGFS EUROPE BV

Netherlands

Superior specially designed rubber compound molded on to the wheel casings, forming an integral wheel assembly that is fitted directly to the equipment. Ideal trouble-free solution for scissor lifts and other ground handling applications.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

2 and 3 axis tilt turn welding positioners for lifting, tilting and rotating the workpiece. The perfect automated solution for lifting, tilting and rotating workpieces of various capacities, shapes and sizes 360 degrees. Key Plant welding positioners are designed to significantly improve the productiveness of your welding and fabrication process. They increase quality and consistency of the weld, both by hand and automation. Their easy to use operation and accessibility with integrated equipment; also significantly enhances operator ergonomics. Available to buy and hire Comprehensive stocks Extensive capacity options Worldwide delivery

Request for a quote

TGS GAS SPRINGS LTD. CO.

Turkey

TGS offers gas struts (lift supports) as aftermarket replacement solutions for cars, commercial vehicles, agricultural vehicles and passenger transport vehicles such as buses, coaches and etc. Tailgates, engine hoods, seat adjustments, cabin windows, rear spoilers, pick-up cap windows, rv hatches are main application examples.

Request for a quoteResults for

Lifting solution - Import exportNumber of results

31 ProductsCompany type

Category

- Lifting equipment (10)

- Lifts and escalators (8)

- Lifting - vehicles (5)

- Lifts (4)

- Goods lifts (4)

- Concrete constructions (2)

- Gas and oil pipelines - installations (2)

- Autogenous welding machines (1)

- Car lifts for garages (1)

- Construction - Machines & Equipment (1)

- Cranes and gantries (1)

- Offshore construction (1)

- Paper - processing machinery (1)

- Shock absorbers, vehicle (1)

- Truck-mounted cranes (1)

- Tunnel construction (1)

- Tyre manufacturing and re-treading machinery (1)

- Tyres (1)

- Wind energy - production (1)