- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser cleaning

Results for

Laser cleaning - Import export

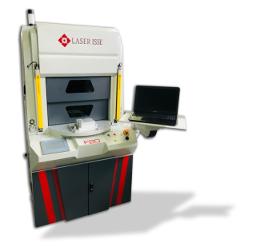

LASER ISSE LASER TECHNOLOGIES

Turkey

Laser cleaning is an exciting new laser process where contaminants, debris or impurities (e.g. carbon, silicon and rubber) are removed from the surface of a material by way of laser irradiation. Not only is this a low-cost solution, it is also the most environmentally friendly application technique compared to the conventional cleaning processes which are widely used in many industries around the world. Laser coating removal is an ablative process whereby laser energy is focused and absorbed by the surface, resulting in vaporization of the coating with minimal effect to the underlying level. This process can be applied to various materials including metal, plastics, composites as well as glass. APPLICATIONS Paint Removal Rust Removal Surface Preparation Facade & Fascia Cleaning Welding & Coating Pretreatment Art Restoration Mold Cleaning Contamination Removal Aerospace Parts Celaning

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Due to their compact and flexible design, LS series laser machines guarantee an easy entry into the world of laser processing. We offer manual and automated solutions: - Palletising systems - Bar and coil feed systems - Pick-and-place systems - Robots You can realize the following laser material processing with the LS series: - laser machining for welding, clean welding, cutting, drilling, hardening, and structuring - micro processing - integration of CO2 , Nd: YAG, diode, fibre or disk-type lasers and ultra-short pulsed laser Please get furher information at Download.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pneumatic nozzle producing semi-fine (and semi-coarse) atomization having a mean droplet diameter of 50μm or more. (*3) High spray impact with thin flat spray pattern and uniform distribution. Liquid pressure type under the liquid pressures of 0.2–0.5 MPa (ca. 2 bar – 5 bar). Large turn-down ratio with stable spray angle. Spray angle of 60° or 80° *1) Measured at compressed air pressure of 0.4 MPa (ca. 4 bar) and liquid pressure of 0.5 MPa (ca. 5 bar). *2) Free passage diameter of nozzle orifice. *3) Measured by Laser Doppler Method. Applications Cleaning: Printed circuit boards, liquid crystal, liquid crystal display, steel plates [Steel making industry] Surface finish process: Precision cleaning for steel surface treatment, Roll cleaning

Request for a quote

SUNALA LIMITED (TRAVTEC GROUP)

United Kingdom

The Travtec range of conveyor accessories has been increasing the efficiency of product manufacturing for over 25 years. Whether you want to code on the underside of aerosol or beverage cans, cosmetic jars and bottles our Diverter and Paratran are designed to operate with your CIJ printer or laser to provide a clean, readable code at any line speed. Our Mini-press, presses the lids & caps onto bottles & jars after hand or mechanical application, preventing wrist strain and other potential injuries. To compliment the machine, our Caplicator can apply the caps & lids before pressing them onto the container. For Tamper-Evident sealing, Our Tiny Tampino Tabletop label applicator is widely used around the world for product security. Our Labelino range of label applicators are used for applying print &self adesive labels to flat & round containers. For labelling or printing corrugated cases the Travtec TR-1000 Casefeeder feeds flat corrugated cases vertically to give 4 side access

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Advantages of Laser Marking System Works with a range of shapes & sizes, Easy to Integrate, Non-Contact, Fast Process, High quality precise marking, Easily adaptable between processes, Permanent marking, Low operational costs, Additional treatment not required, Safe and environment friendly process. We have manufactured and sold 1000+ pulsed laser marking systems worldwide 15+ years of laser application experience We have produced laser engraving and micro cutting systems which are generated by Fiber, CO2, Nd:YAG, UV, Blue and Green Lasers. We have installed systems for global brands We provide project-based automation solutions We are one of the first companies to use laser marking technology in cleaning Available Features; Robotic Integration, Rotary Indexing Table Mark on The Fly 2D & 3D Engraving Feature Auto – Feeder Solutions Precision With Granite Table Integration Existing Production Line Automation Support With 16 I/O Connection

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA CONSUMER GMBH

Germany

Characteristics: - Highest dosing accuracy - Precise closure parts assembly - Flexible servo drives - Turning station with torque control - Greatest possible efficiency - fAccurate transfer at discharge Options: - f100% leak test - Check weighing - Automatic sorting and feeding systems - Die-cut module for lid - Gassing - Ultrasonic sealing - Laser coding - Container cleaning

PRODUCT CONCEPTS

United Kingdom

4 x pk of micorifber cleaning cloths laser edge cutting pink yellow green blue 30x30cm 160gsm MOQ 5000 pcks, 0.44$

Request for a quoteResults for

Laser cleaning - Import exportNumber of results

8 ProductsCompany type