- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- kapton

Results for

Kapton - Import export

Do you sell or make similar products?

Sign up to europages and have your products listed

FRIEDR. FREEK GMBH

Germany

In general, a Kapton film heater is always more expensive than a silicone heater or polyester heater. Where chemical resistance or the weight of the flexible heating element plays an important role, however, Kapton heaters are the ideal solution. The resistance of Kapton Polyimide to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, so that heating elements made of Polyimide (Kapton) are an ideal solution for many critical applications. Kapton foil heaters are also silicone-free and are characterised by an even heat distribution. The dielectric strength of a Polyimide film is very high and so the flexible Kapton (Polyimide) heater can be very thin. Due to the small thickness, the heat transfer to the component is improved and higher surface loads are possible. Typical applications for Kapton film heaters are: Laboratory technology, aircraft electronics, printers, diagnostic instruments, vacuum chambers, medical equipment and many more.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Silicone heaters and Kapton heaters are preferred surface heating elements for laboratory equipment and medical technology due to their easy handling and variety of shapes. Like Kapton polyimide heating foils, silicone heaters are resistant to continuous temperatures of up to 200 °C, with self-adhesive foil up to 180 °C. When designing silicone heaters and Kapton foil heaters, the designer has almost unlimited degrees of freedom. This applies to the minimum and maximum dimensions, which are set within wide limits, as well as to contours and recesses, holes and feed-throughs of any kind. The good shape flexibility of silicone heating mats and foils as well as Kapton polyimide heaters also enables the heating of cylindrical, conical or rounded surfaces. The resistance of polyimides to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, making polyimide (Kapton) heaters an ideal solution for many critical applications.

Request for a quote

ISOVOLTA AG

Austria

we are an authorized distributor of DuPontTM Kapton® throughout Africa and Mexico. We will be happy to supply technical information and datasheets.

Request for a quote

ISOVOLTA AG

Austria

we are an authorized distributor of DuPontTM Kapton® throughout Africa and Mexico. We will be happy to supply technical information and datasheets.

Request for a quote

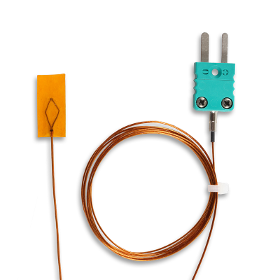

THERMA THERMOFÜHLER GMBH

Germany

This self-adhesive thermocouple is ideal for surface temperature measurements. For both curved and flat objects. The extremely thin wire, not even 1 mm in diameter, facilitates highly flexible installation. The thin probe tip guarantees very rapid response. Temperature range: -100 °C to +150 °C continuous, +260 °C short-duration Adhesive foil: Kapton, approx. 9 x 20 mm

Request for a quote

FRIEDR. FREEK GMBH

Germany

We can offer flexible heating elements manufactured from three different insulation materials: silicone, polyimide (Kapton) or polyester. Each of these materials possess different properties which make them suitable for diverse applications. Silicone heaters can also be produced in very large sizes, whereas polyimide is significantly thinner and polyester unbeatable in price when it comes to high quantities. All three of them are bespoke products made according to your needs, so within the bounds of what is technically feasible you as the customer can determine almost every feature of your heater. This can include; voltage, wattage, dimensions, shape, sensors, leads, plus much more. Due to their low thermal mass flexible polymer insulated heaters distinguish themselves by a very short response time and excellent controllability.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

The adhesive kapton foil as accessory to our self-adhesive thermocouples. Temperatur range: +150°C continuous, +260 °C temporary GoodUV-, aging- and solvent resistance

Request for a quote

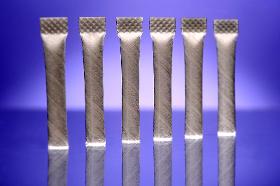

POLITUBES

Italy

Nomex-Kapton -Nomex (NKN) tubes are stator slot liner insulators produced with a low thickness of only 0,16 mm without overlaps. This means an improved thermal management inside the stator slot, less overheating inside, higher torque and motor efficiency, more space for copper hairpins & I-Pins, improved dielectric strength. Reducing the thickness of slot insulator and improving dielectric & thermal insulation is a key stone to improve motor efficiency and performance in terms of: 1. Improving thermal conductivity and reducing thermal resistance 2. Reducing the temperature of the copper hairpin hotspot 3. By reducing the insulator volume because of a reduced thickness and lack of overlaps; this means that the amount of copper inside the slot can be increased, improving motor performance 4. Reducing phase resistance Nomex and Kapton are DuPont registered trademarks

Request for a quote

POLITUBES

Italy

Politubes produces various types of insulating Mylar, Nomex, Kapton, 2LSO, DMD tubes & insulator caps designed according to the requirements of hermetic closure, positioning, size and protection from chemical agents as required by our customers. They can be supplied in perfectly round or oval form to facilitate insertion and to reduce the overall dimensions. Their dielectric strength can reach 303kV/mm with reference to the ASTM-D-149-91 test method and are used within a temperature range of -50°C/+300°C. Our adhesives, carefully selected during our forty years of experience, comply with all REACH and RoHS regulations and guarantee that the original properties of the films used are fully maintained. They are used for insulation and thermal management in stator slot E-Motors, thermal protectors insulation inside electric motors, motor lead termination, compressors, in order to avoid wires ends to damage the surrounding parts

Request for a quoteResults for

Kapton - Import exportNumber of results

15 ProductsCountries

Company type