- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- jet speed

Results for

Jet speed - Import export

SC PROFINOX SRL

Romania

We provide stainless steel sandblasting and grinding services to obtain smooth and clean metal surfaces. The stainless steel sandblasting procedure is environmentally friendly and highly efficient. For finishing metal surfaces, Profinox provides glass sandblasting services – a procedure that does not contaminate surfaces with iron. This consists in propelling glass granules in the form of a jet at very high speeds directly onto the surface of metal parts. As one of the most important aspects reflecting the quality of a product is the finish of the product itself, our stainless steel sandblasting service enables us to perform high-quality surface machining, as sandblasting with glass granules makes it possible to treat even the most difficult to penetrate areas and gives a clean and smooth look to the product. Another important function of stainless steel sandblasting is to significantly improve the final appearance

Request for a quote

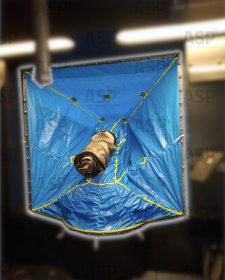

ASP GERMANY

Germany

Customized robot protection covers tailored to your needs: Depending on the jet speed and granulometry, the covers can be made of different fabrics (TORCAL B+ or T1A polyamide fabric). The covers provide reliable protection against various surface treatment agents: steel shot, sandblasting, glass beads, steel beads, ceramic beads, etc. High flexibility and abrasion resistance for effective robot protection. Our protective robot covers are made with welded seams to prevent sand or water penetration, which also meant they are waterproof. Sealed rotating joints on different axes for enhanced seal. Balancers installed to keep the cover in position during the robot cycle. The covers are washable and repairable. Specially designed and integrated metal parts on the robot’s surface to provide protection and freedom of rotation for axes 6 and 4.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

Special high speed adapted ink jet printer with finely adjustable printhead support for marking bandmarks from one side on the fiber at speeds up to 1150 m/min. The usual arrangement allows bandmarking in line with the ink coating process, providing irradiator units after the ink jet printhead and the ink applicator. In case that no additional UV lamp unit and only the UV lamp of the UV curing unit CCD1-K unit is available, bandmarking has to be done in a separate process (either bandmarking or ink coating). The microprogram of the ink jet printer is specially adapted for ultra high speed bandmarking with automatic control of a constant bandwidth over the full speed range. Bandmark pitch and interband distance for multiple bandmarks (double, triple, etc.) are easily programmable on the computer screen. LD - INK LEVEL SENSOR AND INDICATOR SYSTEM FOR INK TANKS Triggers a warning signal as the ink level drops below minimum.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Newly designed slotted jets arranged throughout the entire operating width guarantee constant flow conditions in the drying compartment. Depending on the coating material, the air is heated via hot water, thermal oil or steam in special heat exchangers. Particularly intensive drying is achieved through the high air speed in the jet channel.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Jet speed - Import exportNumber of results

4 ProductsCountries

Company type