- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- installation of pumps

Results for

Installation of pumps - Import export

DRAGFLOW SRL

Italy

Submersible pumps with agitator for charged and abrasive mixtures Main features Pump provided of agitator to stir things up High abrasion resistance Low rotation speed Able to handle up to 70% per weight material density Possibility of installation on mechanical arm Dredging systems (side excavators or dredging head) available on request Accessories: High depth kit Algae cutting blade Humidity and temperature sensor Jet Ring system

Request for a quote

LUTZ PUMPEN GMBH

Germany

When circulating chemicals and pickling baths, reliability, safety and last but not least functionality are important. The submersible centrifugal pump was specially developed as a vertical, wet-installed pump for the rapid emptying of these liquids from tanks and basins. * available in special immersion depths on request * equipped with self-lubricating, liquid-wetted plain bearings. Features & Advantages * High flow rate * High efficiency * Smooth running * Low space requirement * Easy commissioning * Easy to maintain * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C . The measurement is taken at the pressure joint of the pump, without hose, nozzle or flow meter.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KME series was developed as a wet-installed centrifugal immersion pump for stationary use in tanks and basins. The direct-coupled pump with plain bearings is suitable for pumping and circulating neutral and chemically aggressive liquids in the chemical industry and process engineering, in electroplating and surface technology, in washing systems and water treatment plants, for sump drainage in industrial and municipal waste disposal plants or as a circulation pump in gas scrubbers and heat exchangers. * with various plain bearing designs * available in immersion depths from 600 - 1500 mm Features & Advantages * Compact dimensions * Abrasion resistant material combinations possible * Extremely low-vibration and low-wear operation * All wetted parts made of corrosion resistant plastic * Self-centering alignment in the bearing shell

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G1 series (with closed impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern on roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. * Suitable for flow rates up to 30 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G2 series (with open impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern with roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. *Suitable for flow rates up to 80 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

FLUX-GERÄTE GMBH

Germany

The horizontally installed, compact container pump MINIFLUX is designed for emptying IBCs via their floor-level outlet. Designed as an alternative to a vertical pump, the MINIFLUX can be used when an IBC is not accessible from the top. It is suitable for applications when gravity draining via the outlet tap is insufficient e.g. rapid dispensing or transfer to another container in a higher location. Power can ideally be provided by a commutator or compressed air motor. Benefits: - Can be used where ceilings are low - Allows pumping directly from floor-level outlets, even when containers are stacked - Significantly higher flow rate and pressure compared to draining by gravity - Minimal space requirement - Simple disconnection from IBC with union nut - Delivery against closed valve (e.g. hand nozzle, flap valve etc.) possible - Suitable for use in hazardous areas zone 1

Request for a quote

IFA TECHNOLOGY GMBH

Germany

The conveyance of highly viscous products is part of our technical expertise. Feed pumps must meet the requirements for a long useful life, low maintenance and wear-free operation. We at IFA Technology live up to this claim by installing the most suitable pump in each of our systems. We use all types of pumps, from centrifugal pumps to gear pumps and piston pumps. Depending on the type of medium and its application requirements, we can design and offer you the suitable shaft seal. This includes among others packing gland seals, mechanical seals or magnetic couplings.

Request for a quote

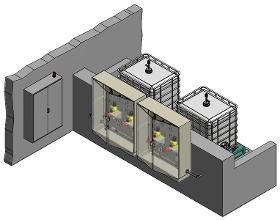

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

STRATE AWALIFTSCHACHT pre-fabricated shafts are used in private, industrial and municipal areas where the installation of sewage pumping stations within existing or planned buildings is not possible. The different design sizes of the pre-fabricated STRATE AWALIFT shafts allow the optimum size to be assigned to every individual AWALIFT pumping station. The possible installation of basement draining pumps in pump sumps is taken into consideration in the shaft dimensions. One-piece compound structure made of glass fibre reinforced plastic (GRP) from a shaft pipe diameter of 1000 mm to 2900 mm, cover and base plate made of reinforced concrete. Absolute water-tightness provides for excellent suitability for further purposes e.g. as an inspection, cleaning or valve shaft. Meets all the requirements of the ATV “Sewage” regulations, which means the pre-fabricated STRATE AWALIFTSCHACHT complies in production and scope of supply completely

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The system comprises two electrodes which are installed above the floor of the pumping station shaft and which issue an alarm message via the connected level relay when they come into contact with water. A sudden water leak in the shaft is detected immediately thus effectively preventing damage. Product features Level relay with connection terminals for potential-free messages for installation in the AWAcontrol control cabinet

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-60 self-propelled grain loader combines the advantages of a PZM-120M grain thrower and an auger grain loader. The grain loading speed and loader capacity are quickly regulated and range from 10 to 70 tons per hour. Unlike a conventional auger, PZM-60 moves independently and loads itself with grain with the existing scraper feeders. The pick-up width is adjustable and reaches 6 meters. During operation of the PZM-60 grain loader, there is practically no dust. The grain loading height is adjustable and ranges from 2.7 m to 4.27 m. The auger is installed on a special platform that rotates 280 degrees around its axis. This allows you to change the direction of grain loading in 2 seconds. The screw rotation speed is easily adjusted by the installed frequency converter. It is also possible to install a hopper on the PZM-60 screw loader. There is also the possibility of using PZM-60 for moistening grain by installing additional nozzles and a hydraulic pump.

Request for a quote

AVK REWAG

Netherlands

Dismantling joints perform an important role in the design and implementation of pipelines including pumps, valves and meters. They provide easy installation and disassembly of valves, pumps and pipe sections. Besides the dismantling joint compensate for axial displacement of the pipe during installation and dismantling. The AVK dismantling joint type Redijo is a double flanged dismantling joint with one follower end-ring.

Request for a quote

KALOPI PEDICURE SPA

Taiwan R.O.C.

Unlike other brands spa installs wash machine drain pump that is really too small for spa pedicure chair. We designed professional drain pump which can move 20 litter water out of tank within one minute. We also install one way value make sure the waste water won’t return to bowl. Timer built inside the pump too.

Request for a quote

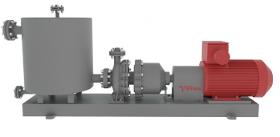

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Witte chemical pumps are used as dosing pumps for a variety of fluids. Pumps of the CHEM series are designed and assembled exclusively at the Tornesch site, thus guaranteeing highest reliability and quality. For all our series we offer a comprehensive spare parts service on request. In addition, we also install the pumps directly at our customer's plant. Dosing pumps of the CHEM series are extremely flexible in their design and can be offered in various variants and equipment thanks to a modular system. Differential pressures up to 120 bar, suction pressures vacuum up to 15 bar Temperatures up to max 500 °C in combination with a magnetic coupling. Viscosities up to 1.000.000 mPas or higher Components made of stainless steel, ceramic and special materials Flow rates from 20 l/h to 170,000 l/h

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump specially designed for use in the production of medical tubing made of TPE, PE or PA. The melt pump is installed downstream of the extruder in the extrusion process for pressure build-up and constant delivery of the melt to the die. It is particularly important for medical tubing that the wall thickness and quality is absolutely constant and uniform.

Request for a quote

MPT DOSING GMBH

Germany

From left to right Dosing system for acid (left) and caustic (right). Sodium hydroxide-dosing system. Chemical-dosing systems are developed and manufactured for various applications and processes as complete, ready-for-connection function modules. Selecting the components and materials for constructing these systems requires long-year experience and comprehensive knowledge of the specific properties of the substances to be dosed. A lot of media are toxic and harmful to persons. Moreover, many are harmful to the environment and the groundwater. Substance properties such as a high viscosity or a high vapor pressure compromise the liability and a safe function if not considered when selecting and installing the pumps. For many years, MPT staff has been working in this specific area and gathered much experience when implementing hundreds of applications for nearly each topic in the range of premium dosing technology. From left to right Sulfuric acid-dosing station. Hardness

Request for a quote

EUROPE ZHAOHAN VACUUM PUMP CO., LTD

Hungary

2ZV5 liquid ring vacuum pump is single stage monoblock design vacuum pump. It offers Space-saving installation, compared to conventional pumps, the 2ZV5's monoblock design delivers the benefits of a simple, compact and economical installation. Since the pump and motor are integral and self supporting, there is no need for additional base plates, couplings or guards, which add to the cost, complexity and overall size of the installation. With CE and Atex certificate, it is an ideal product for much different application including Plastics Industry, Medical Industry, Chemical Industry, Processing Industry, Food and Beverage Industry and other General Industry. We offer same outline dimensions for bolt-on replacement and equivalent performances with original commonly used liquid ring vacuum pump.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Designed as in-tank suction strainer elements for direct installation into suction lines of pumps; should always be installed below the minimum fluid level of the reservoir Features ▪ Available with female BSP thread (ISO 228) or female NPT thread (ANSI B1.20.1) Materials ▪ Threaded end cap made of glass-fibre reinforced Polyamide (PA) or Aluminium ▪ Lower end cap and support tube made of Steel, zinc-plated ▪ Standard filter material is Stainless Steel Mesh (125 μm); alternative micron ratings of 60 μm and 250 μm on request Consult STAUFF for alternative materials. Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Technical Data ▪ Operating temperature range: -20 °C ... +100 °C / -4 °F ... +212 °F ▪ Integrated bypass valve with an opening pressure of 0,2 bar (3 PSI) to reduce the risks of high-pressure drops that can be caused by contaminated strainer elements or high-viscosity fluids Special sizes, designs, materials and...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STOKOTA

Belgium

Vacuum and deep-vacuum units This unit uses a vacuum pump to create a near-full vacuum in the tank. Suction hoses can be connected to the tank to suck wet materials. Deep-vacuum units use two vacuum pumps. Combi units This unit features two functionalities such as a high-pressure and a vacuum installation. It uses a high-pressure pump to clean dirt and debris from surfaces. And it has a vacuum pump which creates a near-full vacuum inside the residue tank to suck wet materials. Combi ‘HP’ units This unit features two functionalities such as a high-pressure and a vacuum installation. It uses a high-pressure pump to clean dirt and debries from surfaces. Pressures of 1000 bar or above can be reached. And it has a vacuum pump which creates near-full vacuum of the residue tank to suck wet materials. Combi sewer units This unit features two functionalities such as a high-pressure and a vacuum installation. It uses a high-pressure pump with high flow rate to clean out dirt, sand, sludge

Request for a quote

REFRA, UAB

Lithuania

High power reversible heat pumps with the heating power from 100 kW to 400 kW are designed for industrial and commercial buildings with large power demand. Manufactured using R290 refrigerant only and full-inverter technology the units are a part of the extremely economical and environmentally friendly Refra product line. With high cooling capacity and many possible extra features these products are widely used in various factories, immense supermarkets and warehouses. These pumps can be used for heating purposes at ambient temperature of -15°or higher as well as for cooling purposes with the capacity of 70 kW to 280 kW. This dual solution is very efficient in terms of price, installation and space, as there is no need to install two separate systems. CJ heat pumps can be made with one to three circuits to ensure continuous system operation in case of emergency – if one circuit is damaged, the others can still use the remaining unit capacity to service the end user.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as inline armature with venting or breather valve function for vessels. Preferably used for installation in pipes. Depending on the installation, the valve can be used as pressure or vacuum valve. It can also be used as non-return safety device or overflow valve.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Leistritz Multiphase pump systems are in operation worldwide. They are designed for running with high gas volume fractions (GVF) and gas bubbles with up to 100% gas content as well as for capacities of up to 5,000 m³/h and differential pressures of up to 150 bar. In comparison with traditional upstream installations, multiphase pumps need neither space-intensive separation devices at the borehole nor separate pumps, compressors or pipelines to transport gas and fluid to the central collection areas. Multiphase pumps are a cost-effective technology for the transportation of multiphase fluids using just a single pipeline - instead of separating the oil, water and gas at the collection areas and exporting the oil and gas to the central production facilities via separate pipelines.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Leistritz Multiphase pump systems are in operation worldwide. They are designed for running with high gas volume fractions (GVF) and gas bubbles with up to 100% gas content as well as for capacities of up to 5,000 m³/h and differential pressures of up to 150 bar. In comparison with traditional upstream installations, multiphase pumps need neither space-intensive separation devices at the borehole nor separate pumps, compressors or pipelines to transport gas and fluid to the central collection areas. Multiphase pumps are a cost-effective technology for the transportation of multiphase fluids using just a single pipeline - instead of separating the oil, water and gas at the collection areas and exporting the oil and gas to the central production facilities via separate pipelines. In general, multiphase pumps are a way to accelerate the unprocessed gas/fluid mixture.

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Filling and mixing lines: Filling and mixing line, height and laterally adjustable Filling and mixing line, with removable mixing nozzle Mixing tube made of hard PVC, rotatable with 1 pipe clamp Filling and mixing line, galvanised steel, can be rotated using socket spanners, height and laterally adjustable mixing nozzle Mixing tube made of completely from hard PVC with flange connection with 1 pipe clamp Mixing tube made of completely from hard PVC with flange connection, height and laterally adjustable mixing nozzle with 1 pipe clamp Mixing unit completely galvanised, rotatable, height adjustable with clamp bracket and flange connection Mixing tube completely galvanised with flange connection, mixing nozzle, height and depth adjustable Mixing nozzle completely galvanised with flange connection, fixed mixing nozzle Tank filling line completely galvanised, fixed mounting, 360 degrees rotatable with flange connection Coupling parts,...

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Eisele submersible pumps AT have been produced by us since 1972 and are used in the agricultural and industrial sectors. Key data: Simple installation Highly efficient For dry and wet installation Aeration equipment (optional) Many different installation variants Pumps also with carriage trolley From 3.0 - 22.0 kW Eisele submersible pumps AT have been produced by us since 1972 and have proved themselves thousands of times. The pumping of slurry with litter, straw or food residues as well as well as waste water sludge is carried out by a special formed inlet nozzle and a screw impeller with armoured Widia steel (for the S version).

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Dual plate check valves to be mounted between tow flanges according to EN 1092-1 Type 11 form B – PN10/PN16. Face to face EN 558-1 row 16 Connection DN50 … DN300 Mounting position Pay attention to the flow direction. Preferably mounting into a horizontal runing pipeline. Make sure to install a minimum of 5 x nominal diameter of straight pipeline in front of and behind the dual plate check valve. Do not install the valves directly onto a pump flange. Pressure range PN10 … PN16, see table Temperatur range 0°C … +80°C Media Non aggressive liquids Material Body: GGG-50, FBE-coated Flap: Stainless steel 1.4408 Stem and spring: Stainless steel 1.4401 Seals: EPDM The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Dual plate check valves to be mounted between tow flanges according to EN 1092-1 Type 11 form B – PN10/PN16. Face to face EN 558-1 row 16 Connection DN50 … DN300 Mounting position Pay attention to the flow direction. Preferably mounting into a horizontal runing pipeline. Make sure to install a minimum of 5 x nominal diameter of straight pipeline in front of and behind the dual plate check valve. Do not install the valves directly onto a pump flange. Pressure range PN10 … PN16, see data sheet Temperatur range 0°C … +80°C Media Non aggressive liquids Material Body: GGG-50, FBE-coated Flap: Steel, nickle plated Stem and spring: Stainless steel 1.4301 Seals: EPDM The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quote

TERMO SHOP D.O.O.

Slovenia

Businesses can reap massive financial benefits from a commercial / industrial heat pump installation with a quick payback and a long service life. For every 1kWh of energy consumed the heat pump can produce roughly up to 6kWh of thermal energy – in some cases the coefficient of performance (COP) can be as high as 10 when using both the heating and cooling effects of the heat pump. Our industrial-grade heat pumps typically pay for themselves within 3.5 years or even less if you receive government subsidies or a grant for the system. As a general rule, the key determinant of heat pump system efficiency is the actual design and installation process. Tailoring the hotel system typically increases output efficiency between 7% and 15% compared to typical installations. Termo+ is currently the only heat pump manufacturer worldwide that works closely with the installation contractors to tailor product parameters for each project.

Request for a quote

TERMO SHOP D.O.O.

Slovenia

Installing an air source heat pump is one of the best routes to savings with amazing returns for home and building owners. For every 1kWh of energy consumed the heat pump can produce up to 5kWh of thermal energy. Our heat pumps typically pay for themselves within 3.5 years or even less if you receive government subsidies or a grant for the system. The TermoPlus® air-source heat pumps require a combination of two units – an indoor unit and an outdoor unit. The indoor unit can either be a Hydrobox, which provides heating only, or a Hydrotank which produces both heating and domestic hot water (for showering, dishwashing etc.). The TermoPlus® air source heat pump range is designed to work with Mitsubishi outdoor units that provide both heating and cooling: either a Power Inverter unit or a Zubadan unit. The main difference between the two is that the Zubadan can operate in colder environments than the Power Inverter.

Request for a quoteResults for

Installation of pumps - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Pumps (12)

- Heat pumps, domestic (4)

- Pumps, hydraulic (2)

- Gear pumps (2)

- Road transport - tankers (2)

- Heat pumps, industrial (1)

- Pump-driven power stations, installations and equipment (1)

- Agriculture - Machines & Equipment (1)

- Centrifugal pumps (1)

- Energy - renewable (1)

- Goods handling systems, continuous (1)

- Industrial maintenance (1)

- Portable electrical pumps (1)

- Refrigeration plants and equipment, commercial and industrial (1)

- Teletext machines (1)

- Vacuum pumps (1)

- Water - production and distribution (1)

- Water-heaters, domestic (1)