- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial cleaning of tools and components

Results for

Industrial cleaning of tools and components - Import export

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quote

P&M TOOLS CONSTRUCTION

Serbia

ALUMINUM CHANNEL THAT HAS CERTAIN CORNERS AT WHICH THE HOSE "BREAKS". AFTER THE REAL HOSE IS DRAWED ONTO THE TEMPLATE, IT IS INSERTED INTO THE FURNACE AT A CERTAIN TEMPERATURE WHERE IT ACCOMPLISHES THE REQUIRED GEOMETRY WITH THE HELP OF CHANNELS.

Request for a quote

LAYTON TECHNOLOGIES

United Kingdom

Single stage IPA solvent vapour component drying machine for critical applications – link to the Vapour Dryer whitepaper. - Does not require Zone 1 & 2 area – can operate in standard production environment. - Marangoni alternative - Water displacement technology. - PLC controlled for ease of use. - Vapour zone - Freeboard area - Ease of maintenance - Flexible process with ease of use via HMI - Retain your existing validated process - Fire protection and suppression systems. - Flammable vapour detection and handling facilities. - Solvent handling to facilitate the safe filling and draining of the process fluids. - Solvent re-processing system. - Internal automated product handling. - Exhausted environmental enclosure. - Primary cooling coils. Cooling water to be supplied by customer facilities or a local chiller can be supplied as optional. - Sealed sliding tank lid. - Manufactured entirely from stainless steel. - Etc. ** Click for more **

Request for a quote

LAYTON TECHNOLOGIES

United Kingdom

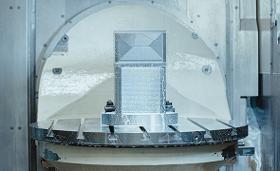

THE ADDITION OF ULTRASONICS TO THE MAJORITY OF CLEANING PROCESSES CAN REDUCE THE REQUIRED CLEANING TIME BY UP TO 80%. These hermetically sealed, modular stainless-steel submersible units are designed for use in new systems or retrofitted into existing systems to give you the benefits of ultrasonic capability. In order to obtain the best results, the number and location of transducers within the parts cleaning tank is determined based on the geometry of the parts cleaning tank and the type of contamination to be removed. The immersible transducers are designed for use in a heavy, industrial environment. The hermetically sealed welded housings are manufactured from 316 stainless steel and undergo a rigorous testing procedure prior to installation. The modular nature of the bolt-in units allows for flexibility with regard to the location of the submersible units and ease of access for service & maintenance … ** Click for more **

Request for a quote

LAYTON TECHNOLOGIES

United Kingdom

For precision component cleaning & degreasing applications. - For use with all aqueous detergents - All tanks manufactured in Staffordshire. - All stainless-steel construction – traceability certification available. - Pickled, passivated and electro-polished to extend operational life. - Heated tank utilising direct contact tube heaters for energy efficiency and longevity. - Thermostatically controlled. - Bolt-in removeable ultrasonic transducer plate. - Bolt-in ultrasonic transducers ensure minimal downtime and extend tank life. - Multi-frequency ultrasonic transducers. All ultrasonics use sweep frequency technology. - Separate ultrasonic generator. - Industrial standard – continually rated. - Insulated frame. - Basket and lid inclusive. - Table top or bench inset mounted. - Operates from standard mains voltage. - CE Certified – UL approval also available. - Etc. ** Click for more **

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LAYTON TECHNOLOGIES

United Kingdom

For precision component cleaning applications particularly, validated processes. - Designed to safely use all low-flashpoint solvent cleaning media including IPA, Cyclohexane & Acetone. - Does not require Class 1 Div 1 area – can operate in standard production environment. - All machines manufactured in UK. - All stainless-steel construction – traceability certification available. - Specialised fabrication available if required. - Pickled, passivated and electro polished to extend operational life. - Heated tanks have direct contact tube heaters for energy efficiency and longevity. - Drop-in ultrasonic transducers and heaters ensure minimal downtime and extend tank life. - Multi-frequency ultrasonic transducers. All ultrasonics used sweep frequency technology. - On board distillation ensures clean solvent continuously - Small footprint designed for clean room applications - Etc. ** Click for more **

Request for a quoteResults for

Industrial cleaning of tools and components - Import exportNumber of results

7 ProductsCountries

Company type