- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic system servicing

Results for

Hydraulic system servicing - Import export

ADIS FRANCE

France

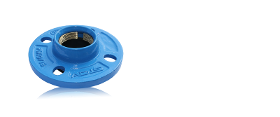

PARTS FOR MOUNTING AND SERVICING HYDRAULIC SYSTEMS Locked flange adapter for PE pipes and hoses BMAIN CHARACTERISTICS - Made of ductile cast iron EN-GJS 400 - Blue epoxy anti-corrosion coating - Pressure rating: 10 or 16 bar - For PE pipes - ISO PN10 and PN16 drilled flanges up to DN150, from DN200, ISO PN10 or PN16 drilling to be specified. or PN16 drilling to be specified - Complies with EN 545 - A.C.S. certified product

Request for a quote

ADIS FRANCE

France

PARTS FOR MOUNTING AND SERVICING HYDRAULIC SYSTEMS Ductile iron mounting joint MAIN FEATURES - Ductile iron body EN-GJS 400 - Blue epoxy anti-corrosion coating - Pressure rating: 10 or 16 bar - Galvanised or chrome-plated nuts and bolts - Complies with standard EN 545 - A.C.S. certified product

Request for a quote

KW HYDRAULIK GMBH

Germany

Cable cutting unit in several sizes for cutting cables, in case of failure under voltage.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Eurobalt Engineering is an Estonian company specializing in manufacturing metal parts by using various technologies. Our products are shipped to the countries of the EU, Asia, and the CIS. One of our major business areas is the production of parts for hydraulic cylinders. Nowadays, competition in the hydraulic cylinder market is a challenge that cannot be underestimated. Decisive factors are price and quality – both of them strongly depend on the efficiency of production and procurement chains of a hydraulic cylinder factory. Our company offers a one stop solution for a hydraulic cylinder factory – we can produce and deliver all kinds of metal parts for hydraulic cylinders so that the factory can focus on assembly and save time and efforts, usually spent on in-house machining. Some examples of the hydraulic parts that we are currently producing: PISTONS END CUPS OF CYLINDERS HYDRAULIC CYLINDER HEAD GLANDS PISTON RODS CYLINDER HOUSING TELESCOPIC PISTONS

Request for a quote

MCS HYDRAULIC&PNEUMATIC

Turkey

We have every type of hydraulic fittings.

Request for a quote

MCS HYDRAULIC&PNEUMATIC

Turkey

We have power units at difference dimensions and features.

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

Special units 1000 to 50000 liter tank volumes, standard aggregates, motor / pump assemblies, valve stands, storage stations, filter cooling circuits, lubrication systems, engineering and delivery compl. tube sets

Request for a quote

ALS HYDRAULIC

Turkey

We have power units at difference dimensions and features

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Hydraulic power units are produced in close cooperation with customers. Highly-qualified technical and commercial marketing staff are continually working to meet the needs and wishes of our customers and their problems from the field of hydraulics. Gidrolast offers our customers knowledge, expertise and experience in solving such problems. Gidrolast engineering knowledge is a core competence of projecting processes. In this process, our engineers design hydraulic power units to customer requirements, all necessary documentation is prepared and risks and production capabilities are assessed and the whole project is prepared for execution. In the sales process, the customer gets a full quotation. The whole process of monitoring the execution of customer’s order is carried out by the business information power unit. In order to delivery process the hydraulic power unit is produced, tested, adjusted and prepared for transport on the basis of technical documentation.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

From the sticky tar sands of Uzbekistan and the frozen windswept wastelands of Ural to arid, sun -leached Texas and the sizzling hot deserts of Saudi Arabia; from the warmth of the Caspian sea to the cold salt spray of the ocean, Gidrolast hydraulic cylinders are the actuators of choice in the gruelling oil field industry, both onshore and offshore. Oil rigs are located in some of the most demanding locations in the world. Blowing sand, sticky tar, extremes of hot and cold temperatures, corrosive elements and heavy-duty use. The cylinders used are often large-bore and long-stroke. Downtime is measured in millions of dollars. In addition to all that, the equipment is often located in remote areas far from civilization. Rugged, reliable cylinders are a must. Gidrolast designs and builds heavy-duty hydraulic cylinders, both rod style and telescopic, to withstand the tough conditions and demanding requirements of the petroleum industry.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast knows heavy trucks. We cut our teeth building hydraulic cylinders for heavy trucks all the way back in 1993. Hydraulic cylinders on trucks are subjected to all forms of contamination that would destroy a poorly designed cylinder. Dirt, grit, rain, salt, tar, chemicals, solvents and cleaning agents all combine to attack the cylinder and its seals. Despite all this, the cylinders are still expected to perform. Cylinder failure means downtime, employee overtime, loss of vehicle availability, less productivity and reduced profit. Gidrolast cylinders are built tough to meet these conditions. They can be found mounted on garbage trucks, dump trucks, belly dumpers, semi end dumpers, boom trucks, knuckle boom loaders, road pavers, concrete mixers, concrete pumps, mobile cranes, tilt beds and tow trucks. Applications include dump cylinders, aerial boom cylinders, compaction cylinders, outrigger cylinders, tilt cylinders, swing cylinders, plough lift cylinders, and more.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast got its start in building rugged hydraulic cylinders for use on heavy trucks in the waste management industry way back in 1994. That means we know first-hand what is required to build cylinders that will tough it out in this industry. So whether the cylinder is operating the gate on a garbage truck or the grapple in a scrap metal yard, the compactor on a scrap baler or lifting the blade of a bulldozer in a land fill site, Gidrolast cylinders are built to last. Both OEMs and end users around the world appreciate the rugged reliability built into each of our cylinders. Careful, experienced design is combined with high-quality manufacturing to make our Gidrolast hydraulic cylinders the cylinders of choice in waste management and recycling equipment. It’s not hard to see why tough, reliable cylinders are required in the waste management and recycling industry, as these pictures clearly testify. Hydraulic cylinders are shown in action in a scrap metal yard above.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

KREA

Turkey

Tanks for Hydraulic Power Units and mobile Hydraulic or Diesel Tanks

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HYDRAULIK SCHWERIN GMBH

Germany

Our standard range was developed with regard to technical and economic aspects especially for the increased requirements in machine and plant manufacturing. Steel and aluminum manifolds, adapter, blind and intermediate measurement plates are in stock at any time, allowing us to quickly meet your urgent requirements for various pressure stages. All plates have corrosion protection (zinc-plated or anodized).

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Hydraulic clamping systems from AMF: powerful, precise and flexible. The hydraulic clamping systems from AMF include a wide range of components, which in turn are available in many different designs. This means that we are able to offer fully developed technology with different features tailored precisely to the needs of the different areas of use.

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

HYDROFORMA, LTD

Ukraine

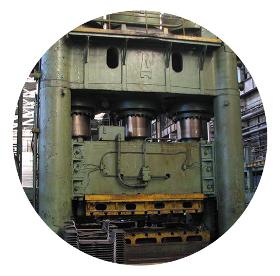

Press Features: Rated force: 400 kN; Working stroke: 300 mm; Working pressure: up to 160 bar; Running time: 33 seconds; Total power of engines: 4 kW; Power supply: 380 V, 50 Hz; Control: semi-automatic (sensors); Dimensions: 1100 * 1000 * 2110 mm Weight: 2,5 t.

Request for a quoteResults for

Hydraulic system servicing - Import exportNumber of results

26 ProductsCompany type

Category

- Hydraulics systems (15)

- Cylinders, hydraulic (6)

- Machine tools - metal machining (4)

- Presses, hydraulic (2)

- Assemblies, hydraulic (1)

- Cocks and valves (1)

- Cutting - steels and metals (1)

- Cylinders - combustion engines (1)

- Hydraulic tools (1)

- Platform hoists (1)

- Pumps, hydraulic (1)

- Stamping - machine tools (1)