- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic supplies

Results for

Hydraulic supplies - Import export

AZ MACHINERY

France

Brand: AZ RAMP- Type: FORMATION 2020 ADJ- 8T-ZR-STV Rated Capacity: 8,000 Kg Dimensions: Overall length: 16.18 m Overall Width: 2.22 m - Useful Width (Inside): 1.94 m Length Inclined plane / Inclined part: 6.60 m Length Height Flat-shaped horizontal: 1.10 m Integrated Hydraulic Leveling Wharf (Power Supply 220 V- 50 Hz) Lifting Height: Min: 0.60 m - Max: 1.55 m Support feet, 2 integrated dock stops with refuge zone of 500 mm. Side safety rails, height: 1.20 m, removable Non-slip bearing surface, and hot-dip galvanized Pre-drilled support legs The + Product: specially designed for forklift school. Designed for use with self-mounted trans-pallet, 3 and 4-wheel forklift. Vertical platform of 45.64 m² to turn around with a trolley type 3 electric wheels

Request for a quote

AZ MACHINERY

France

loading ramp with integrated hydraulic dock. Brand: AZ RAMP- Type: FORMATION 2020 ADJ- 10T-ZR-STV Rated Capacity: 10,000 Kg Dimensions: Overall length: 16.18 m Overall Width: 2.22 m - Useful Width (Inside): 1.94 m Length Inclined plane / Inclined part: 6.60 m Length Height Flat-shaped horizontal: 1.10 m Integrated Hydraulic Leveling Wharf (Power Supply 220 V- 50 Hz) Lifting Height: Min: 0.60 m - Max: 1.55 m Support feet, 2 integrated dock stops with refuge zone of 500 mm. Side safety rails, height: 1.20 m, removable Non-slip bearing surface, and hot-dip galvanized Pre-drilled support legs

Request for a quote

MOOG GAT GMBH

Germany

GAT torsion motors are supplied as individual components or as complete torsion system consisting of torsion motor unit, application-specific control electronic s and hydraulic supply. Comprehensive consultation services from concept planning phase to commissioning complement our portfolio. GAT torsion motors consisting of a basic motor and a GAT rotary union are designed for quasi-static, pulsating and dynamic loads. Speed and torque as testing parameters are controlled independently. The torsion test rig with mechanical torsion application allows the energy-efficient testing of components at relatively low investment costs. Using a hydrostatic torsion motor in the test rig creates realistic and consistent testing conditions leading to test results very close to real-life conditions.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

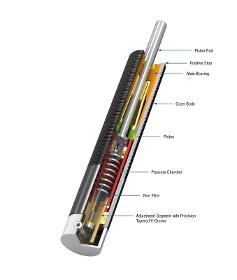

Adjustable Compression Force max. 3,500 N Stroke 15 mm Precise adjustment for any type of application: The VC model of hydraulic feed controls is ideally suited for the precise tuning of constant feed rates. The thread of the outer body of this closed hydraulic element allows simple assembly. Designs with a smooth body can also be supplied. As the hydraulic oil is forced out through the throttle opening, a constant feed rate is achieved on the stroke, which also avoids the stick-slip effect. In the models up to 55 mm stroke, the tried and tested rolling diaphragm, known from ACE shock absorbers, serves as a dynamic seal, as volume compensation of the piston rod and as a reset element.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

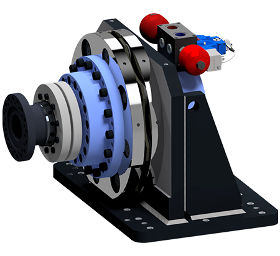

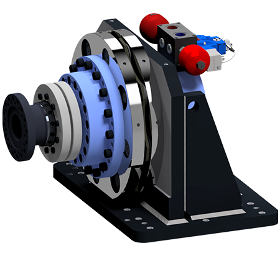

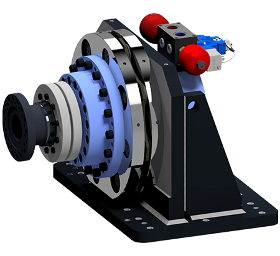

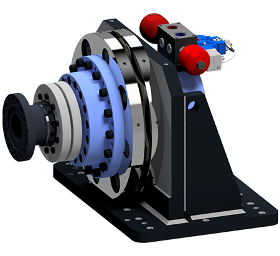

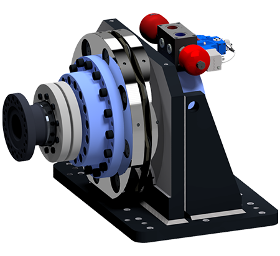

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply EPS-EPP shape moulding machines, suitable for various applications, product types and mould sizes. While our traditional range of machines is of hydraulic types, we can also supply electrical shape molding machines as well. You can learn more about our products and services by visiting our web site - https://www.estechtic.net/ or you can send your inquiries to fr@estechtic.net.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

Product characteristics of the Disc clutches The shifting clutches mostly serve as a connection that can be activated or disconnected between the power and work units, such as the gear and pump, or in similar installation situations. The disconnection is achieved via the system's existing media supply. (hydraulics, pneumatics) Areas of use of Disc clutches The disc clutches are used in mobile applications, agricultural and forestry machines, sweeping machines and many other areas in mechanical engineering.

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

CNC Lathe; 25.5" x 80" (648 x 2032 mm) max capacity, 12.5" (318 mm) bore, 34.5" (876 mm) swing, 55 hp (41 kW) vector drive, 1000 rpm, 2-speed gearbox, front and rear A1-20 spindle noses, 12-station bolt-on turret, programmable servo tailstock, 15" color LCD monitor, memory lock keyswitch, USB port, color remote jog handle and rigid tapping. No chuck or rotating hydraulic union supplied. Standard toolholder kit included with BOT turret. ST-55 Dimensions Shipping Dimensions

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

CNC Lathe; 25.5" x 80" (648 x 2032 mm) max capacity, 7.0" (178 mm) bore, 34.5" (876 mm) swing, 40 hp (30 kW) vector drive, 1400 rpm, 2-speed gearbox, A2-11 spindle, 12-station bolt-on turret, programmable servo tailstock, 15" color LCD monitor, memory lock keyswitch, USB port, color remote jog handle and rigid tapping. No chuck or rotating hydraulic union supplied. Standard toolholder kit included with BOT or Hybrid turret. ST-45L Dimensions Shipping Dimensions

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

CNC Lathe; 25.5" x 44" (648 x 1118 mm) max capacity, 7.0" (178 mm) bore, 34.5" (876 mm) swing, 40 hp (30 kW) vector drive, 1400 rpm, 2-speed gearbox, A2-11 spindle, 12-station bolt-on turret, 15" color LCD monitor, memory lock keyswitch, USB port, color remote jog handle and rigid tapping. No chuck or rotating hydraulic union supplied. Standard toolholder kit included with BOT or Hybrid turret. ST-45 Dimensions Shipping Dimensions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IPR GMBH

Germany

Technical data UNI FUTURE with pressure transducer Pressure needs detection with switch-off upon reaching the required working pressure of 20 bis 850 bar Suitable for all tools with a oil flow to 700cm³ With built-in-pressure sensors for enhanced features and advanced settings Jogging for intermittent tool feed Power stepless adjustable, short time possible to 1,2 kW For Network and battery (24/230V) Powerful Li-Ionen battery 24 V 4,8 Ah The unit is designed so that the battery capacity is sufficient for one working day. Integrated charger Energy savin mode – Unit switches off 10 minutes after the last activity, or to low battery charge Shutdown at idle after the working cycle, prevents tool damage and saves energy Robust plastic housing Controls and coupling are set back behind the front edge of the housing Flow rate: automatically adjust to 1l/min Size L/B/H: 215 x 165 x 220mm (Handle height 40mm) Weight: ca. 6,9 kg SUPPLIED WITH Hydraulic power unit 3m Remote control 3m Power charger adjustable shoulder strap instruction manual

Request for a quote

IPR GMBH

Germany

Technical data ED 100 To drive the nitrogen charging apparat «SL 230 SLG» and all crimping and cutting tools. Designed for continuous use Maximum pressure: 850 bar Delivery volume: up to 0,8L/min Fitting to all tools with oil demand up to 700cm³ Shiftable automatic detection of pressure requirement with switching off at the Essential working pressure from 20 to 850 bar Built in pressure sensor for improved functionality and enhanced adjustment Inching function for interrupted tool infeed Robust housing, operating elements and coupling are built in secured under body top Weight: ca.14 kg Supplied with Hydraulic power unit 3m Remote control 3m Power charger adjustable shoulder strap instruction manual

Request for a quote

IPR GMBH

Germany

Technical data cube with pressure transducer and lock valve Pressure needs detection with switch-off upon reaching the required working pressure of 20 bis 850 bar Suitable for all tools with a oil flow to 700cm³ With built-in-pressure sensors for enhanced features and advanced settings Jogging for intermittent tool feed Power stepless adjustable, short time possible to 1,2 kW For Network and battery (24/230V) Powerful Li-Ionen battery 24 V 4,8 Ah The unit is designed so that the battery capacity is sufficient for one working day. Integrated charger Energy savin mode – Unit switches off 10 minutes after the last activity, or to low battery charge Keeps the pressure of max. 850 bar upon actuation of the stop valve Robust plastic housing Controls and coupling are set back behind the front edge of the housing Flow rate: automatically adjust to 1l/min Size L/B/H: 215 x 165 x 220mm (Handle height 40mm) Weight: ca. 6,9 kg The lock valve for pipe crimping tools prevents reduction of oil pressure in the tool. So it is possible to hold hydraulic pressure over not time limited space. Supplied with Hydraulic power unit 3m Remote control 3m Power charger adjustable shoulder strap instruction manual

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The portable HD 2500 is designed for delivering high hydraulic pressure up to 2500 bar required for operating hydraulic tools, especially hydraulic tools for loosening and tightening the clamping connections provided at large diesel engines. Capacity hydraulic pressure up to 2500 bar. Drive medium Compressed air with at least 6 bar. Features The hydraulic pressure is adjustable up to 1500 bar. Up to four hydraulic tools can be supplied simultaneously.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The portable HD 1500 is designed for delivering high hydraulic pressure up to 1500 bar required for operating hydraulic tools, especially hydraulic tools for loosening and tightening the clamping connections provided at large diesel engines. Capacity hydraulic pressure up to 1500 bar. Drive medium Compressed air with at least 6 bar. Features The hydraulic pressure is adjustable up to 1500 bar. Up to four hydraulic tools can be supplied simultaneously.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With press capacities between 15 and 500 MN, Siempelkamp's closed-die forging presses oer the optimal solution for numerous application areas. The optimal relationship between press dimension and press force oers our customers maximum benets. Best process and system parameters are the guarantee for high dimensional and repeat accuracy. Siempelkamp supplies hydraulic closed-die forging presses for many dierent application areas. According to the application area, guidance accuracy, cycle time, eccentricity, and speed are optimally adjusted with one another. Depending on the customers' requirement, Siempelkamp's closed-die forging presses are available in dierent designs - as push down and pulldown presses. If desired we can supply these presses as part of a complete solution, from the press segment to the forging plant.

Request for a quote

RUHFUS SYSTEMHYDRAULIK GMBH I.L.

Germany

Power units and Control Systems Ruhfus Systemhydraulik GmbH specialises in the production of special solutions in the field of hydraulic units for industrial use. In order to be able to optimise the product to meet your requirements, you will be supported during the whole project phase by our competent team. Ruhfus Systemhydraulik GmbH can supply hydraulic units with tank sizes of up to 10,000 litres capacity. For this we use DIN oil tanks but also special tanks that are individually adapted to your needs. Here it is immaterial whether the oil tank is made of steel, stainless steel or aluminium. For special designs such as table valves, tank support frames, supporting structures for motor pump units and many more special components connected with your hydraulic unit we are of course likewise the right people to contact. For each of our hydraulic units, 3D models are generated beforehand which can be made available to you. From these you can plan earlier the field piping, possible foundations or building and also transport or other matters in detail. For the drives of our hydraulic units we use standard electric motors with a power of up to 80 kW. On request the motors can also be equipped with a frequency converter. As the valve technology, as well as the oil supply unit, are always subject to customer-specific requirements, limits are always hard to define here. As far as possible only two limits should not be exceeded, on the one hand a maximum volume flow of 275 l/min and on the other a maximum system pressure of 315 bar. Furthermore we can offer you the supply of a complete system of cylinder and hydraulic unit to electric control. If you a seeking a competent partner in the “complete solution” area, we will be glad to support you with our team. 3 D Models

Request for a quote

IZUMI PRODUCTS (UK) LTD

United Kingdom

Hand operated hydraulic cable cutter supplied with canvas carry bag. Cutting of piano wire is prohibited. Cutting capacity. Wire rope 6х7:18 mm Wire rope 6х12:24 mm Wire rope 6х19:24 mm Soft steel bar:20 mm Reinforcing rod:16 mm Cu strands:24 mm Al strands:24 mm ACSR : 24 mm Guy wire 1х7:20 mm Guy wire 1х19:20 mm CCP cable:N/A

Request for a quoteResults for

Hydraulic supplies - Import exportNumber of results

26 ProductsCompany type

Category

- Electric motors and parts (7)

- Presses, hydraulic (4)

- Construction - Machines & Equipment (2)

- Industrial and technical training (2)

- Clutches (1)

- Cylinders, hydraulic (1)

- Electric cables (1)

- Forming - steels and metals (1)

- Hydraulic brakes (1)

- Mechanical engineering - custom work (1)

- Mechanical transmission systems and components (1)

- Pneumatic clutches (1)

- Thermoforming, plastics - machinery (1)