- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- horizontal saws

Results for

Horizontal saws - Import export

PRESSTA EISELE GMBH

Germany

Variable notching possibilities for mullion and transom combinations, e.g. curtain walls, winter garden, sky lights and special designs. Notch variation: rectangle, one sided angular, two sided angular, 3 sided angular Notch dimensions: 210mm horizontal, 262 mm vertical (90°) Profile dimensions: height maximum 280mm, width maximum 320mm 4-axis adjustment of saw blades positioning via electronic control panel – Notch height – Swivel vertical blade – Swivel vertical and horizontal blade together – Material depth stop Power adjusted notch height – positioning via control panel 0 – 260 mm Power adjusted pivoting range saw blade vertical 90° – 60° + 30° (to front/to back) Power adjusted pivoting range horizontal + vertical saw blade 90° + 45° – 45° Pivoting range material fence on table manually left/right 30° – 90° – 45°, positioning by scale Depth stop power adjusted via control panel. Precise and safe notching due to the work piece is fixed on the table during the cut Hydro...

Request for a quote

PRESSTA EISELE GMBH

Germany

Variable notching possibilities for mullion and transom combinations, e.g. curtain walls, winter garden, sky lights and special designs Manual adjustment of the horizontal blade max. 20mm to the front to cut slots Notch variation: rectangle, one sided angular, two sided angular, three sided angular Notch dimensions: 185mm horizontal, and 210mm vertical at (90°) Profile dimensions: height maximum 280mm, width maximum 300mm Manual adjustment of saw blade height, positioning via mechanical digital display; electronic display optional Swivelling range vertical saw blade 30°-90°-30° (back/mid/front) positioning via mechanical digital display Swivelling range of both, horizontal and vertical saw blade, 30°-90°-30°, positioning by mechanical digital display Material fence on the table swivelled left / right 30°-90°-30°, positioning by scale Depth stop adjustable via hand wheel and slide, read out by mechanical digital display, manual clamping Semi-automatic precise and safe notching...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

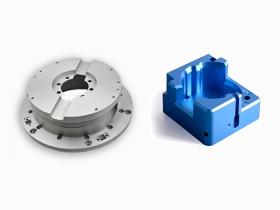

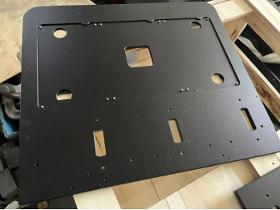

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

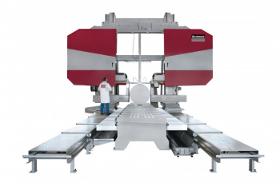

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROSAW LIMITED

United Kingdom

The Bomar Workline 410.280DGH is a semi-automatic mitre bandsaw and is an ideal basic model for the production of steel structures. The both-sided mitre cuts continuously adjustable within the 0–60° range, with a large, easy-to-read angular scale. This machine features also an easily movable clamping vice for mitre cuts and a full-stroke hydraulic vice with a tightening system. Bomar Workline 410.280DGH Standard Details: 2 way mitre – 60° right, 60° left Easy to read mitre scale DRO for mitre angle Long stroke hydraulic vice Powered bow raise Adjustable back off valve for optimising downfeed speed relative to material mass Control box mounted on swinging arm Simple, robust push button controls Variable blade speed 20 to 120m/min Dovetail sliding vice for mitre cutting 27mm blade width Bed height: 756mm

Request for a quote

YILMAZ MACHINE

Turkey

SK 450 is designed for the strait cutting operations of the large size of profiles made of PVC and aluminum by means of Ø450 mm of saw blade at 90°. It is ideal for the serial and precise slicing operations. Suitable for high-volume slicing of aluminum profiles for window manu facturing and industrial applications High precision servo motors and inter nationally recognized components Saving of time by means of servo con trolled workpiece infeed speed and saw blade stroke Horizontal and vertical clamping of the workpiece during the sawing operation Automatic table retraction feature that moves the cut material a small amount after cutting and before the blade came back down to prevent the re-cut & scratches High cutting accuracy by means of the robust mechanical structure Programmable spray saw blade lubrication system via control panel Large memory capacity for the cutting programs The machine shut down automatically after reaching the requested quantity

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION DC 421 MS is designed for the strait or angular cutting operations of large size of profiles made of aluminum and PVC materials by means of double head sawing units equipped with Ø 420 mm of saw blades. Two-hand run safety operation Manual adjustment of intermediate tilting angles from 90° to 45° inwards Hydro-pneumatic saw blade feed Cutting accuracy +/- 0.2 mm Manual positioning of cutting units Solid steel construction of the body Conveyor & 2 x pneumatic profile supports Automatically closing safety guards Horizontal pneumatic material clamps to ensure optimum material fixing STANDARD ACCESSORIES • Equiped with Ø 420 mm of saw blades • Roller conveyor & 2 x manual profile supports • 4 x horizontal clamps • Air gun • Spray saw blade lubrication system OPTIONAL ACCESSORIES • Profile Length Stop for cutting short pieces (DKN 70 with digital unit, DKN 71 with ruler) • Machine with the length of 5m and 6m • VCE 1570 Chip vacuum extractor

Request for a quote

CASEARTECNICA BARTOLI SRL

Italy

The panel saw machines perform the horizontal cutting of cheeses of all sizes and consistencies, both hard and semi-hard. Starting from the basic model, the manually operated bench disconnector suitable for delicatessens and small businesses, the range of disconnectors also includes electric and automatic machinery, developed for intensive use, typical of industrial realities. They offer the possibility to cut a large number of cheeses with maximum precision and without any effort or loss of product.

Request for a quote

DISPA MACHINE

Turkey

• Semi-automatic double miter for cutting profiles and solid material in steel and non-ferrous material and an excellent price-performance ratio • Manually swiveling saw frame with hydraulic clamping for optimal • Hydraulic clamping of the horizontal vise • Automatic saw frame raising on the cut end • Double speed motor 1.0/1.3 KW Gearbox • Sensitive cutting pressure regulation function of the material properties • Hydraulic-mechanical belt tension • Tape guide with hard metal pads sheets and rolls • Thermal overload protection and no-volt release • Automatic shut-off after cut end • Automatic belt break protection Driven

Request for a quoteResults for

Horizontal saws - Import exportNumber of results

11 ProductsCompany type