- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat forms

Results for

Heat forms - Import export

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Feature: Heat Insulation and Low Thermal Conductivity; Application: Extrusion & Injection Moulding; Customized: Yes and contact for material solution.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of temperature-stressed machine parts, e.g. rolling bearings, friction bearings, slideways, chains, rollers or moving parts in hot forming, heat treatment or drying Dry lubrication, e.g. of kiln and rack-truck bearings, bearings of pouring ladles, converters or hot-air blowers at temperatures over 250°C Lubrication of plastic and rubber at normal temperature when the materials concerned are not resistant to mineral oil Advantages and benefits Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Broad range of applications at temperatures up to 200°C as paste, over 200°C to 450°C as dry lubricant Resistant to water, fuels and lubricants, chemicals and hydraulic fluids For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner.

Request for a quote

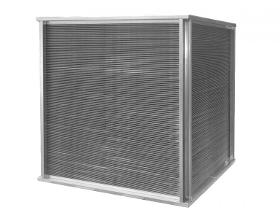

UNEX HEATEXCHANGER ENGINEERING GMBH

Austria

High performance plate type heat-exchangers consist of a number of formed, sealable heat-exchange plates according to the respective requirements. The alternating pressed plates and channel spacing cause highly turbulent flow behaviour, optimal self cleaning effect and highest possible heat transfer. Use of high-grade materials such as titanium, titanium palladium, highly alloyed steels and even a UniCarb carbon/graphite version help ensure UniGasket heat-exchangers are extremely economical compared to other heat-exchanger types. The plates are clamped to a rack between frame plate and pressure plate by means of clamping bolts.

Request for a quote

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

KUZEY GLOBAL

Turkey

Synchronized forming and cutting by tilting movable lower platen to 80 degrees Sheet pitched by double toothed chains and move on abrasion resistant slide plates; Lengthened pan design allows to reach optimum forming heat without using pre-heater machine Upper and lower Mold ; heats control by indivudial Thermoregulation device Fine adjustment for mold by electric drive. Traversing and tilting moving system of mould PLC for control the line operation and supervise working parameters Opportunity to set one or more forming cycles without cutting by pneumatic drive High production capacity with resistant to high speed Strong and vibration free main body Double inlet- outlet system for fast cooling by increasing water discharge. Energy analyzer which gives amount of the electric consumption Cutting adjustment possible by digital meter ,controlled by PLC. Plug asist motor

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

ELETTROIDEA SRL

Italy

Removable 4-sided cover in NIKO fabric with Resistex Bioceramic, which, thanks to the action of bioceramics, returns body heat in the form of FIR rays that can penetrate into the skin’s layers and activate the microcirculatory system, boosting metabolism. Resistex® Bioceramic has a high level of thermal insulation, which makes it possible to maintain a constant body temperature also in extremely cold conditions. Pocket spring mattress comprising 7-zone memory foam layer with massage function, high bearing capacity Aquafoam pocket spring sheet with 1600 pocketed springs. This allows a progressive and self-modelling reaction. The set of springs distributed over SEVEN ZONES responds with pressure proportional to weight, allowing the mattress to follow the body’s natural shape in a balanced manner.

Request for a quote

ELETTROIDEA SRL

Italy

Removable 4-sided cover in NIKO fabric with Resistex Bioceramic, which, thanks to the action of bioceramics, returns body heat in the form of FIR rays that can penetrate into the skin’s layers and activate the microcirculatory system, boosting metabolism. Resistex® Bioceramic has a high level of thermal insulation, which makes it possible to maintain a constant body temperature also in extremely cold conditions. Highly breathable Super Fresh layer that ensures a fresh feeling together with complete ergonomic comfort. 3 supporting layers of HR Foam, open-cell water-based foam, a highly resilient and highly elastic material. This product is breathable, environmentally friendly and non-deformable. Soft hypoallergenic fibre for the upper part, breathable fabric on the lower part of the mattress that ensures air circulation.

Request for a quote

ALUMINIUM RESIDENCY WORLD LTD

Bulgaria

Door and window systems with a thermal barrier MB-70HI, MB-70US HI and a curtain wall based on the MB-70CW HI windows. Their construction is based on well-proven, well developed and highly appreciated base systems, i.e. MB-70, MB-70US i MB-70CW. Enhanced thermal insulation performance is achieved due to placing special insulating inserts in the central insulating chamber, formed by connecting aluminium profiles with thermal breaks. Thus formed inserts reduce heat transfer through this chamber due to low value of heat transfer coefficient. The central location of inserts additionally limits convection and thermal radiation.

Request for a quote

3P GULF GROUP

Saudi Arabia

3P Shrink Wrap Film is an LDPE coextruded blown lm, serves as protective wrapping for articles of merchandise. It consists of clear plastic lm that is wound around the articles and then shrunk by heat to form a sealed, tightfitting package (Shrink package). Polyethylene (PE) Plain & Printed Shrink Films used as Multipack are much in demand for the Juice & Beverages Industries. PE Plain & Printed Rolls are for the packaging application (FFS) in Food & Detergent industries a very fast growing Packaging sector Worldwide.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Keep Your Steam Clean, Safe And Energy-Efficient Steam is an essential resource is many industrial processes. As a result most facilities have a vast network of piping, valves, flanges and steam traps. Within these systems there exists constant flow and turbulence. As pure steam travels from your boilers to their point of use, some cooling is inevitable. The result is accumulated condensate and gases. Steam traps purge this waste and keep your system pure. A fully-functional steam trap opens, closes or modulates automatically. It discharges condensate once formed, unless the heat from the condensate can be used. It is energy-efficient and does not waste quality steam. It removes impurities from the live steam, and maintains purity and efficiency throughout the system. Steam Trap Failure Causes Losses to Product Quality, Safety and Energy Loss Steam traps are necessary for the overall efficiency of heat energy transfer.

Request for a quote

FOSHAN YINI TECHNOLOGY CO., LTD.

China

This heat pump dryer is used for drying different materials, it adopts heat pump working heat dissipation principle to form airflow to dry industry and agriculture materials, this type of heat pump with the features of intelligent, low cost, temperature controllable and so on. Wide application, can be used in agricultural products, seafood, fruits and vegetables, fish, meat, nut, herb, wood drying systems. Intelligent temperature control, auto temperature adjustment, energy saving, high energy efficiency, easy installation, preferred material + mature process

Request for a quote

TEKNO KESIM

Turkey

we use standard EVA foam with a 75 Kg/m3 density. It has a 5–100 Shore A hardness. It is produced as a plate of 1000 x 1500 mm. Thickness of EVA plates starts from 1,5 mm and goes up to 38 mm which fits our EVA cutting process very well. As it has a high temperature tolerance, it can be molded by heat (thermo-form). EVA foam is resistant to heat starting from -40° C till + 90° C . It is a soft and flexible material. It can be with design on it. It is waterproof. It is antibacterial, free of hazerdous chemicals. It is available in various colors. As Tekno Kesim, we do EVA cutting for you by laser, cnc, waterjet or die cut for eva foam cutting. We have mentioned above the characteristics of EVA and due to these and the area you need to use, EVA cutting is prefered. As it has a very good suction ability, for sensitive items and electronic devices we make case inserts or box seperators by EVA cutting. It has many advantages like providing high protection and stylish appearance.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Rollstock vacuum skin packing machine suitable for medium and large batch packaging enterprises. It is mainly formed by heating and stretching through the lower film, then filling the packaging into the formed tray, entering the heat sealing vacuum chamber to vacuum the packaging. skin-to-body vacuum packaging adheres to the surface of the product like a second skin, which can firmly lock in moisture. Vacuum body packaging, with refrigeration can greatly extend the shelf life. Improve the appearance value, strong three-dimensional sense, transparent and beautiful, easy to touch and inspect, and neat and beautiful.The product is fastened to the tray, which can be shockproof, anti-friction, and anti-scratch; and vacuum-sealed, which can prevent moisture, oxidation, etc., to protect the quality of the product. From automatic forming tray-manual feeding-automatic packaging-automatic cutting-automatic output, etc., it can be completed automatically at one time, greatly reducing labor.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The automatic continuous stretch vacuum packaging machine is mainly formed by heating and stretching through the lower film, then filling the packaging into the formed lower film cavity, and then entering the heat sealing vacuum chamber to vacuum or inflate the packaging, and put the upper. The film is heat-sealed with the lower film to form a packaging bag, and the packaging is divided by cross-cutting and longitudinal cutting. The finished product output of packaging can be completed automatically at one time, the operation is simple, the labor force is greatly reduced, and the difficulty of recruiting is solved, thereby improving the product quality, beautifying the production environment, improving production efficiency, saving time, labor, and efficiency, etc. Real automation equipment. Application: All kinds of meat,fresh meat, aged meat, sausages, Seafood fish,Dried fruits,Vegetables ,Ready to eat meals,Cheese, Pasta, noodles totally dried cereals, corn kernels, peanuts, etc.

Do you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Compression Proof and Form Stable Biaxial expanded Joint Sealant Characteristics No change in width at compression Excellent on slim or restricted flange area Technical parameters pH 2 - 12 Temperature: t = -200 … +280 °C Pressure: p = Vacuum … 200 bar Density: 0,95 g/cm 3 Main application Larger flanges and vessels Glaslined flanges Agitators Heat exchangers Form of delivery 10 mtr / roll Other length and dimension on request Suitable for Pharmaceutical industry Food industry Approvals FDA21 CFR 177.1550 (PTFE), FDA21 CFR 170.105 (adhesive) EG 1935:2004 EU 10/2011 FDA Installation Instructions Connect the ends with an angle cut Maximum uneveness of flange: 1/3 of seal tape’s thickness Dimensions thickness (mm) Recommended for Steel Flanges width according DIN 2690 (NW) Surface pressure/ resulting thickness in 10 N/mm2 Surface pressure/ resulting thickness in 20 N/mm2 Surface pressure/ resulting thickness in 30 N/mm2 Surface pressure/ resulting thickness in 40 N/mm2 2 ≤...

Request for a quote

TURKEYRAF

Turkey

Maximizes heat transfer with D Form aluminum pipe winding, provides extraordinary performance with 71mm insulation thickness. Dust-proof condenser does not require maintenance, it is long-lasting thanks to its aluminum frame and electrostatic powder painted and galvanized coated inner and outer body. Apple Series with its negative (Static), positive (dynamic) or dual regime options and large volume, provides minimum energy consumption. Apple is suitable for installation types such as singular, block and land, and allows you to create different layouts in the Market.

Request for a quote

ERC ADDITIV GMBH

Germany

ERC Guard Thermic for low-sulphur heating oil with a bio share and all other DIN heating oils slows the natural ageing of heating oil and contains an organic combustion enhancer. The Effect ERC Guard Thermic slows the natural ageing of heating oil. Stabilisers prevent components of the heating system from releasing into the heating oil and forming sediments, and/or accelerating the ageing of the heating oil. In the process, select active ingredients neutralise the ions already in the heating oil and apply a protective coating to the metal surfaces, which suppresses the release of new ions and protects against corrosion. In addition, the additive prevents the formation of resin-like, adhesive ageing products which arise due to the high thermal load of the heating oil within the pump and can block it. At the same time, lubrication of the pump is improved.

Request for a quote

KSL

Ukraine

KSL provides quality services of welding of various metals Metal welding is the process of fusing two metal parts together, using heat and pressure to form a strong metal bond. Heat is generated by an electric arc or flame, and pressure is applied using a welding tool. The process of welding is to melt metal surfaces and blend them together to form a homogeneous mass of metal. There are several welding methods, including MIG, TIG, and arc welding. Welding is rightly considered one of the most popular metalworking processes, which is found in many metal products. Main characteristics of KSL metal welding: Semi-automatic welding; Argon welding; Spot welding; Condenser welding. You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #spotwelding #weldingstainlesssteel #aluminumwelding #metalwelding #tigweldingaluminum

Request for a quote

PERO AG

Germany

The R5 units from PERO are able to clean large quantities as well as large workpieces in a highly efficient manner with short cycle times. Thanks to its large-capacity processing chamber, the R5 is particularly popular with companies in the automotive and aerospace industries, as well as those of forming plants, heat treatment specialists and contract cleaners where high cleaning capacity is a must. Suitably dimensioned tanks guarantee excellent degreasing and cleaning results in single-shift and multiple-shift operation, even at high throughput rates. Cleaning Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Highlights - High flexibility - Maximum throughput - Unrivalled cleaning quality Availability Available as 1- and 2-bath unit with loading of the unit via - Hall trolley - Pallet truck - Automatic charging unit

Request for a quote

PERO AG

Germany

The R4 from PERO is able to clean large quantities of parts as well as large workpieces in a hgihly efficient manner with short cycle times. With its high cleaning capacity, the R4 meets the needs of companies in the automotive and aerospace industries, as well as those forming plants, heat treatment specialists and contract cleaners. Thanks to customised parts carriers and logistics concepts, the R4 offers reliable degreasing and cleaning results for emobility suppliers. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Suitable for 1/2 EURO wire mesh boxes Suitable for largesize workpieces Efficient cleaning to high cleanliness standard Available as 1 and 2bath unit with loading of the unit via Hall trolley Pallet truck Automatic charging unit

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

iwis Leaf chains (according to works standard) are produced from precision chain parts according to ISO 606. They can be customized and are compliant with the EC Machinery Directive 2006/42/EC. Highlights - iwis link plates with very high tensile strengths - Pins with extra hardened surface for high wear resistance - Precision-formed, heat-treated and shot-peened link plates with optimised geometry - Higher breaking forces achieved by optimised plate thickness - Improved press-fitting of pins and outer plates for higher fatigue strength - Link plates with a particularly high contact ratio - Pins with hardened surfaces for increased wear resistance - Special versions manufactured to works standards available

Request for a quote

HERSCHEL INFRARED LTD

United Kingdom

Our Advantage and Aspect space heating ranges are revolutionising the way businesses can heat people indoors. Infrared heat warms you directly without heating the air in between: so the heat goes where you want it to and doesn’t just convect upwards to heat the ceiling. With input power requirements of 1300 – 2600 watts these low watt-density heaters give a far higher equivalent heat output compared with hot air or gas-burning “space ray” type heating systems or other forms of electric heating often used in these environments. Additional benefits: Silent operation, without fumes – consequently raising no health and safety issues; Cheaper installation than oil or gas alternatives – all you require is electric cable; No maintenance; Zoning so heat is “focused” exactly where you want it; No red glow; Lower consumption levels.

Request for a quote

FIS MODULAR SYSTEMS LTD.

Russia

Modern rolling machine with heated bins for forming two-component products and products filled with a filler made of marshmallows, biscuits, aerated marmalade, soufflé, and other semi-dense masses. It ranges from delicate meringues, soufflés, and marshmallows to dense masses such as qurabiya dough. You can use it to work with minced meat for gastronomic production! IntelleMix performs the functions of dot depositing, dotted line depositing, as well as a continuous extrusion process (marshmallow sticks, cookie sticks, fondant, etc.).

Request for a quoteResults for

Heat forms - Import exportNumber of results

32 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (3)

- Beds, bedsteads and mattresses (2)

- Cleaning machines, industrial (2)

- Induction heating systems (2)

- Plastic packaging (2)

- Thermoforming, plastics - machinery (2)

- Bedroom furniture (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Confectionery - machinery and equipment (1)

- Foams, plastic (1)

- Freeze drying - machinery and equipment (1)

- Fuel oil (1)

- Heat exchangers (1)

- Heat pumps, industrial (1)

- Heat recovery systems (1)

- Industrial equipment hire (1)

- Joinery and carpentry - works (1)

- Mechanical transmission systems and components (1)

- Monitoring and control equipment (1)

- Polymers (1)