- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat accumulator tank

Results for

Heat accumulator tank - Import export

LLC RPE TEPLOBAK

Ukraine

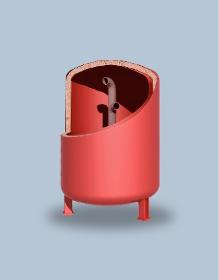

The heat accumulator VТА/V-1 is assembled from two different tanks in size, in the space between them is created an average vacuum (0,1 mBar) and filled with insulating powder (λ=0.007-0,01W/m∙K). Compared to traditional heat accumulators, the VTA/V-1 minimizes heat loss for effective heat storage. Its powder-vacuum insulation (PVI) replaces the standard 100cm of urethane-foam isolation. PVI’s thermal conductivity ranges from 0.007 to 0.01W/m∙K, significantly lower than rock wool (0.06W/m∙K) and urethane foam (0.04W/m∙K). The VTA/V-1 occupies similar space to traditional models. Key benefits include: — capacity of 2000-10000 liters; — possibility outdoor installation; — underground installation capability; — up to 10 times better thermal insulation in comparison with analogues; — absolute insulation moisture resistance; — long-term heat retention(ideal for heat pumps and solar collectors); — stable temperature stratification of heat carrier through the system of stratification.

Request for a quote

LLC RPE TEPLOBAK

Ukraine

The VTA/N "Tank in Tank" heat accumulator features a stainless steel tank inside a carbon steel tank. This design combines the benefits of both a storage tank and a heat accumulator, allowing for simultaneous use in heating systems and hot water storage. The inner tank is made from high-quality food-grade stainless steel with a wave-shaped wall for increased resistance to pressure, improved heat exchange area, and self-cleaning through thermal expansion. The VTA/N-1 model includes a carbon steel heat exchanger at the bottom for optional connection to solar collectors or other heat sources (heat pump, gas, solid fuel, electric boilers). The VTA/N-2 model lacks a heat exchanger, allowing direct connection to any heat generator. The VTA/N-1-SOLAR PLUS model has an enlarged inner tank partially placed within the heat exchanger, improving efficiency with low-temperature heat sources.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Beside the protection against external effects as UV or other external effects which could damage the foil, the unique construction enables a reliable and measureable leak test as well as an accurate filling level measurement at all times. Compared to low pressure systems and double membrane gas accumulators the Lipp system has very low operation and maintenance costs.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The range of material grades available and individually customisable pumping and stirring technologies provide optimum boundary conditions for any substrate composition. Pre or post treatment of the substrate can be carried out by installing additional tanks (e.g. hydrolysis, sugar beet silos and post digesters). With Lipp tanks for biogas plants which are built and used all over the world, you will benefit from 50 years of experience in plant and tank construction. They are constructed using VERINOX stainless steel which is characterised by maximum leak tightness and high quality. Stainless steel digester with a digester chamber volume of 100 to 10,000 m3 Wide range of tank roofs With or without optional gas accumulator Flexible stirring technology which can be adapted to the digester and substrate Smooth internal walls and uniform temperature distribution

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

CONTAINER AND SYSTEM SOLUTIONS FOR THE INTERMEDIATE STORAGE OF HEAT FROM WASTE HEAT OR RENEWABLE ENERGIES The intermediate storage of heat from biogas plants, biomass cogeneration plants or other heat sources is an important prerequisite for effective use. Lipp buffer tank systems are economic system solutions for the storage and supply of thermal energy and can be easily integrated into customised solutions for local heat supply. LIPP BUFFER STORAGE TANKS The individually tailored solution appropriate to heat storage requirements with useful volumes of 80 to 3,000 m³ is made of stainless steel with the Lipp dual seam system and operated in conjunction with insulation adjusted to the application at about 95 ° C. Since the Lipp system is unpressurised, the container solutions are extremely low maintenance and are very durable. The high volume, above ground Lipp storage tanks have been specially developed for this application and are popular with end users and energy suppliers alike.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

COST EFFECTIVE SYSTEM FOR THE NON PRESSURISED STORAGE OF BIOGAS, LANDFILL GAS AND SEWAGE GAS In biological processes, gas production is not continuous. That is why the utilisation of gas (e.g. in a combined heat and power plant) requires an accumulator in order to compensate for fluctuations during gas production and to bridge downtimes for plant repairs and maintenance. Besides high functional and operating safety, other important criteria for the construction and operation of gas tanks include the economic aspects of investment and maintenance costs. DVGW approval held High functional and operating safety Highly accurate radar measurement enables exact content to be displayed Low investment and maintenance costs Quick construction Low maintenance Long service life Leak tightness can be checked

Request for a quote

LLC KUIDYCH (KHT)

Ukraine

EAM Buffer Tanks: Efficient Heating Solutions High-Performance Insulation: Up to 2000 liters: 80mm removable thermal insulation. From 2500 liters: 100mm soft polyurethane foam. Key Features: Vertical Pipe Alignment: Facilitates easy and convenient connections. Electric Heating Socket 1 1/2": Option for additional heating. Vertical Nozzle Alignment: Suitable for cascading connections. Technical Specs: Insulation Class "C": Ensures top-tier thermal insulation. Max Pressure 3 Bar, Max Temp 95°C: Reliable and safe operation. EAM Buffer Tanks are engineered for efficient heat storage and distribution. Ideal for diverse heating and hot water applications, they offer top-notch insulation, flexibility in connection, and safety in operation. Upgrade your heating system with EAM for optimal performance and energy efficiency.

Request for a quote

OZKAN GUNES ENERJI SIS. SAN. VE TIC. LTD. (OGES)

Turkey

enamel coating sörpentine boilers

Request for a quoteResults for

Heat accumulator tank - Import exportNumber of results

10 ProductsCountries

Company type