- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hand-mould castings

Results for

Hand-mould castings - Import export

ZS INDUSTRIES CO., LTD

China

Material:Grey Iron: GG15, GG20, GG25, GG30 Ductile Iron: GGG40, GGG45, GGG50, GGG60, GGG70 Process: Resin sand casting, Film-covering sand casting, Clay sand casting, Hand molding and machine molding Application: Agricultural machinery, Off-shore industry, Printing machinery, Waste treatment machinery, Concrete plant equipment, Packaging machinery, Pumps

Request for a quote

ALUMINIUM GIETERIJ OLDENZAAL B.V.

Netherlands

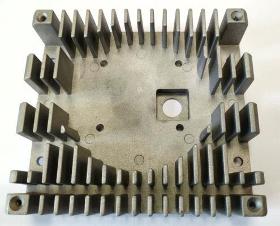

In our ultra-modern and well-equipped hand-moulding foundry we can produce single pieces up to medium-sized batches for you. We use organic and inorganic sand systems, depending on the application and the requirements of your product. The experience and know-how we have accumulated over the years guarantee the solution from which you will benefit to achieve an optimal product. Our strengths Complex components Pressure, vacuum and gastight castings Single pieces to medium-sized batch production Skilled employees Several sand systems available Flexible Innovative Advantages of hand-moulded sand casting Relatively low investment costs for the model Good accuracy of measurement and surface quality High freedom of moulding Flexible process Short lead time for production start-up Relatively easy to make changes

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Material: custom size: according to drawings Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

MVA D.O.O.

Slovenia

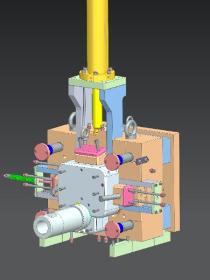

We offer product design consultations, tool designing, mould manufacturing and mould maintenance and service.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion. We outsource aluminum die castings from our friend factory, then do further machining process, finish treatments. sales@mxmparts.com

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quoteResults for

Hand-mould castings - Import exportNumber of results

8 ProductsCountries

Company type