- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- groove ring

Results for

Groove ring - Import export

ARUBIS

Belgium

Molded corrugated Sleeves specially developed for SWECO® gyratory equipment. Inside diameter with groove, which corresponds to bead ring of the inlets and outlets. These sleeves can be produced in a variety of standard sizes. These sleeves have cuffs allowing easy and secure clamping upon handling the product. Arubis has decades of experience and will assist you in finding the correct sleeve depending on the intended application.

ARUBIS

Belgium

Molded corrugated Sleeves specially developed for SWECO® gyratory equipment. Inside diameter with groove, which corresponds to bead ring of the inlets and outlets. These sleeves can be produced in a variety of standard sizes. These sleeves have cuffs allowing easy and secure clamping upon handling the product. Arubis has decades of experience and will assist you in finding the correct sleeve depending on the intended application.

ARUBIS

Belgium

Molded corrugated Sleeves specially developed for SWECO® gyratory equipment. Inside diameter with groove, which corresponds to bead ring of the inlets and outlets. These sleeves can be produced in a variety of standard sizes. These sleeves have cuffs allowing easy and secure clamping upon handling the product. Arubis has decades of experience and will assist you in finding the correct sleeve depending on the intended application.

ARUBIS

Belgium

Molded corrugated Sleeves specially developed for SWECO® gyratory equipment. Inside diameter with groove, which corresponds to bead ring of the inlets and outlets. These sleeves can be produced in a variety of standard sizes. These sleeves have cuffs allowing easy and secure clamping upon handling the product. Arubis has decades of experience and will assist you in finding the correct sleeve depending on the intended application.

WIB SA

Switzerland

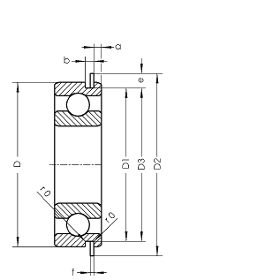

For certain applications, it may be appropriate to use ball bearings fitted with a snap ring fixed on the outer ring. The dimensions of the N groove and the snap ring R are are defined by the ISO 464 standard. The bearing is available in two versions, according to the customer’s requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIB SA

Switzerland

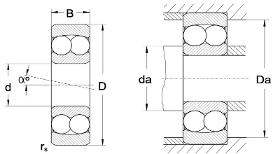

Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring. This type of ball bearing is recommended when alignment of the shaft and housing is difficult, and the shaft may flex. Unlike a single row or double row ball bearing, the self-aligning bearing’s performance will not be affected by misalignment. Therefore, they are particularly suitable for application where misalignment can arise from errors in mounting or shaft deflection inherent in the application. These bearings are made with seal or without seal.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Measuring groove widths for selecting locking ring classes

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

These sliding rings are the solution for designs which only allow room for a small or low housing. They are ideal for retrofitting into existing O‑ring grooves

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

These sliding rings are the solution for designs which only allow room for a small or low housing, but require an operating pressure up to 80 Mpa. They are ideal for retrofitting into existing O‑ring grooves

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application With the PVM1 assembly set, worn valve guides can be quickly and easily removed from the cylinder head and new valve guides inserted into the cylinder head. The assembly set is particularly suitable for motorcycle, car and commercial vehicle workshops. Features The air hammer can also be used to drive valve seat inserts out of the cylinder head. For this purpose a Hunger valve seat turning device is used to turn a groove into the valve seat ring. The seat ring is driven out of the cylinder head by means of a clamping head whose expandable clamping elements engage in the groove. Handling Insert the appropriate drift pin into the pneumatic hammer and insert the drift pin into the valve guide. Switch on the compressed air supply with the control lever provided on the pistol grip of the air hammer. The valve guide is driven out of or into the cylinder head by the rapid impact sequence. A soft protective ring placed on the drift pin protects the valve guide from damage.

Request for a quoteResults for

Groove ring - Import exportNumber of results

11 ProductsCountries

Company type