- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding

Results for

Grinding - Import export

OREMUS S.R.O.

Czech Rep.

We do it all without blinking, but in protective glasses.

Request for a quote

OPSIL LTD

Bulgaria

We can facet blanks with a diameter up to150 mm, and also rectangular wafers. Facet dimension – up to 5 mm. Edge grinding accuracy 0,1 mm.

Request for a quote

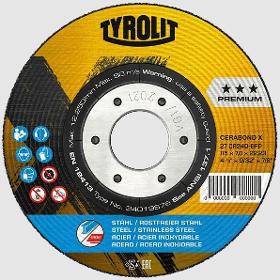

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our files, bench stones, knife blade files and hollow chisel stones are available in different grit sizes from coarse to super fine depending on the desired application. Due to the large selection of different tools, the portfolio covers a wide variety of applications. The various files and stones can be used for machining tools in the woodworking and machine industries as well as for whetting knife blades. Tyrolit combination stones consist of two different grit sizes, allowing a wide variety of workpieces to be deburred. For improved ergonomics, certain products are equipped with handles to increase working comfort and make hard-to-reach places effortless to machine. One tool that no workshop should miss is the TYFIX hand rubbing brick, which allows you to effortlessly remove dirt, rust and paint from various surfaces. Tyrolit's tools are designed for different materials - from vitrified-bonded tools to resin- and electroplated diamond files for HSS and tungsten carbide.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit's rough grinding wheels meet advanced economic requirements with high stock removal rates, ease of handling, and long life. Our innovative wheels ensure optimal results in both standard and special applications. In steel working, demands for better standing times, higher stock removal, and shorter machining are crucial. The CERABOND X range, with high-grade ceramic grain and innovative bond structure, meets these challenges, excelling on hard steel types and large diameters for economical processes and excellent results. Enhanced Safety and Comfort VIBSTAR reduces vibration by up to 50%, counteracting occupational diseases. SILENTIO reduces noise by 10 decibels, preventing physical damage and increasing comfort. "Comfort Start" technology ensures optimal performance from the start. High-Quality Grinding Wheels Tyrolit’s 1F80 range for straight grinders offers low-vibration work with high stock removal rates on steel, stainless steel, nonferrous metals, and cast iron.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers a wide range of tools for the manual and automated finishing of cast workpieces in foundries. These include cutting discs for angle grinders and stationary machines as well as roughing discs in various degrees of hardness. Resin-bonded tools and diamond grinding discs offer maximum service life and precision for the automated machining of grey and nodular cast iron. Tools for all requirements In addition to cutting and grinding discs, the range also includes mounted points and carbide burrs for straight grinders and industrial robots, which are ideal for hard-to-reach areas. A large proportion of the products belong to the PREMIUM segment, which speaks in favour of the high quality of Tyrolit tools. Advantages of the Tyrolit range: . Variety of shapes and dimensions . Long tool life and cutting ability . Consistently high performance . Above-average comfort

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit rollers are the result of continuous innovation aimed at improving this product segment. The high quality of our tools provides numerous advantages, especially for general grinding tasks like cleaning and finishing. Our rollers ensure consistently high-quality results on uneven surfaces throughout their lifetime. With a broad range of applications, they are ideal for removing welding marks, scratches, oxidation residues, and large-scale surface pretreatment. New to Tyrolit are spiral rollers with a patented shape that facilitates easy, comfortable work while preventing typical roller marks. Our rollers for floorstand grinders are perfect for finishing, polishing, and cleaning uneven or curved surfaces made of steel, stainless steel, and nonferrous metals. Available in various grit sizes, they cater to different needs: 40-60 for high stock removal, 80-120 for medium grinding, and 150-320 for a perfect surface finish.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

The Tyrolit strip range offers surface treatment tools for industrial and maintenance applications. These strips ensure high efficiency and excellent surface quality for cleaning, deburring and finishing work on metals, composites and plastics. They remove rust, paint and corrosion without damaging the material. Made from durable abrasives, they are available in different grits and compositions and are suitable for manual and automated systems. Tyrolit strips increase productivity in industries such as automotive, aerospace, construction and manufacturing.

Request for a quote

KIGEMA SP. Z.O.O

Poland

Bearings, sliding bearings, half bearings, bushes, worm gears, sealing rings, gears, shaft, screw nuts, rings, sleeves and plain bearing, stator parts, slot wedges, spacers, washers, covers, copper and steel parts, epoxy insulating materials, machining off retaining rings, coils, fans, slipping rings, spacers wedges. APPLICATION SECTORS Our clients are manufacturers of special machines for the processing, paper, automotive, aviation industries, and many others. We have extensive experience in making parts for electrical machines such as electric motors and generators for power plants throughout Europe. For many years we have supplied spare parts for generators renovated by ALSTOM, ETHOS ENERGY and GE Power.

Request for a quote

KRANAMAX

Bulgaria

Machinery: With a strong emphasis on metal processing, Kranamax Ltd boasts a wide array of machinery to ensure precision and efficiency in the fabrication of metal structures and components

Request for a quote

HANNECARD GROUP

Belgium

Hannecard provides over a thousand custom-made roller covering solutions, from rubber and polyurethane to composite and spray coating. To improve the lifespan and performance of the roller coverings, we are constantly developing new compound formulations.

Request for a quote

ALLIED FOR TECH

Poland

We perform grinding mainly on endless belts, as well as with the use of special grinders and hand-held power tools.

Request for a quote

APERTE, UAB

Lithuania

Dimensions range - Minimal - 80 x 80, Maximal - 6000 x 3000, 6000 x 2800, 3600 x 2200, Thickness range - 3* - 19, 3* - 19, 3* - 19, Edge type - The line for edge grinding, Double edge processing, Four edge processing, Notes - C-bevel Trapezoid **Blunted *** The matt or polished edge, C-bevel Trapezoid ** The matt or polished edges, C-bevel Trapezoid ** The matt or polished edges. * Glass with a thickness of 3 mm we don’t finish of trapezoidal profile. **Finishing of trapezoidal profile is performed by peripheral grinding wheels with not adjustable width phase of 0.5 mm. ***Blunting is performed on customer request in order to prevent of accidental laceration during glass installation, as well as in the case of glass designed for tempering, if any treatment of edges foreseen.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The SG 175 support grinder is designed for grinding the conical seating surface of valves of medium speed diesel engines on a standard lathe. Handling The support grinder is clamped in the toolpost located on the top slide of the lathe. The grinding angle corresponding to the required valve seat angle is adjusted by turning the top slide of the lathe to an angular position which corresponds to the valve seat angle and which is defined by the template supplied with the grinder. The valve stem is clamped in the chuck of the lathe and the valve face is ground by feeding the grinding wheel into the rotating valve face. Features The precision grinding spindle is permanetly sealed and lubricated for lifetime accuracy. The wheel guarding system is designed to the prevailing safety regulations. The cone-shaped head of the template is provided with a bore receiving the dressing diamond so that the grinding wheel can be properly dressed after adjustment of the grinding angle.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Selfcentering Steady (Option) Selfcentering steady rests are available to fit on the swivel plate slideway for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the swivel plate to clamp each valve on that part of the valve stem which normally travels in the valve guide. The combination of collet chucking and the unique Hunger steadying provides double support of long valves to ensure the ultimate in valve refacing accuracy. Oscillating Equipment (Option) An oscillating equipment for automated power traverse of valve face across the grinding wheel is available to ensure efficient stock removal and superior finish. The stroke of oscillation is infinitely adjustable. Automated Infeed (Option) Power infeed is available for automatic grinding according to a preselected program. The feed rate, the total infeed and the sparkout time can be easily selected.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning. The machine base houses also the control panel for the motors. Grinding Spindle The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway. The swivel plate is set to the desired valve angle by means of a wide spaced scale. Steady Rest An unique selfcentering steady rest is provided for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning. The machine base houses also the control panel for the motors. Grinding Spindle The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway. The swivel plate is set to the desired valve angle by means of a wide spaced scale. Steady Rest An unique selfcentering steady rest is provided for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated slideway for wheelhead. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled coolant tank which can be drawn out for ease of cleaning. Workhead and Steady Rest Both the workhead and the steady rest are adjustable along the swivel plate to clamp each valve on that part of the valve stem which normally travels in the valve guide. The combination of collet chucking and the unique Hunger steadying provides double support of long valves to ensure the ultimate in valve refacing accuracy. Automated Oscillation An oscillating equipment for automated power traverse of valve face across the grinding wheel is available as an option to ensure efficient stock removal and superior finish. The stroke of oscillation is infinitely adjustable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTHER TROWAL GMBH&CO.KG

Germany

INDIVIDUAL SOLUTIONSIf you are searching for a custom solution for your mass finishing processes, the TT...B series is the best choice. The modular system allows you to fit the individual machines with feeders, screening machines and abrasive media return transport systems as required. ELECTROMECHANICAL OR HYDRAULIC SYSTEMS AVAILABLE The work bowl can be pivoted either electromechanically (TT 25, TT 45) or hydraulically. You can also partially automate processing with the respective peripheral devices such as feeding and separating units. THE BENEFITS AT A GLANCE Individual mass finishing solution Modular system Choose from electromechanical or hydraulic system Partial automation possible

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

TT...SM CENTRIFUGAL DISC FINISHING UNITCOMPACT AND PIVOTING Centrifugal disc finishing units from the TT...SM range have an attached screening machine and integrated hopper for abrasive media. After processing the workpieces, the entire unit pivots by 135° to separate the abrasive media and workpiece mass on the screening machine. SUITABLE FOR HIGH-VALUE WORKPIECES While the system pivots back into the working position, the abrasive media are conveyed back into the work bowl. This centrifugal disc finishing unit is particularly well suited to processing high-value workpieces, making it a popular choice in the aerospace industry for example. THE BENEFITS AT A GLANCE Compact design saves space Cost effective Suitable for processing limited quantities

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

CONTINUOUS TROWALIZING OF NON-SENSITIVE PARTS The AV range of continuous units allows you to continuously process large quantities, with no need to interrupt the mass finishing process to add new workpieces. Thanks to the trough-shaped work bowl, you can process small and medium non-sensitive mass-produced parts (punched parts, die-cast parts, etc.), as well as larger parts (oil tanks, cylinder head covers, etc.). THE BENEFITS AT A GLANCE Continuous workpiece processing Interruption-free workpiece loading Trough-shaped work bowl Easy to integrate in fully automated mass finishing processes Simple material handling without batch loading

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

OUR ENTRY-LEVEL MODEL – EFFICIENT AND COST EFFECTIVEThe circular vibrators of the CF series are a perfect and simple introduction to mass finishing. The seven different configurations, with a range of different bowl sizes, offer excellent efficiency and maximum cost effectiveness. The CF circular vibrators are easy to operate and can be expanded with accessories for sound deadening or metering, for example. PROCESSING AND SEPARATION – SMOOTH MASS FINISHING The work bowl with an evenly rising floor is perfect for processing your workpieces, as the zero-maintenance vibration flange motor works at two different speeds. The pneumatic separator flap and long separation zone allow you to gently separate your workpieces from the abrasive media. This creates a smooth mass finishing process with excellent results.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

MV multivibratorsThe finishing touch for complex shapes If you have workpieces with hard-to-process contours that require fine finishing or polishing, the multivibrators of the MV series are the ideal choice. The respective workpiece is secured mechanically or electromagnetically, and processed using vibrating abrasive media and special fluids. This ensures a consistent finish on both the internal and external surfaces. Automated internal finishing on premium parts Our multivibrators each have three high-speed imbalance drives that allow you to vary the position and rotation direction. This enables extremely small vibration amplitudes, ensuring high surface quality for your workpieces – even on difficult-to-reach areas. Delicate bars are protected, the workpiece contours are retained, and even small-diameter boreholes can be processed internally.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Robust mass finishing machines with separation zone The CD series of circular vibrators are robustly built and stand out thanks to their wide range of potential uses. From polishing and smoothing to deburring, the integrated screening unit helps easily separate workpiece and abrasive media using a manually or pneumatically powered separator flap. The CD circular vibrators are available in configurations from 110 to 1,200 litres of gross volume. Perfect configuration for large workpieces Thanks to the flat bowl bottom and the large opening between the bowl bottom and the separator flap, processing your large and sensitive workpieces is easy. CD circular vibrators also have a large separation zone for simple separation of flat components. The benefits at a glance — Integrated screening unit — Manually or pneumatically powered separator flap — 110 to 1,200 litres gross volume — Flat bowl bottom — Extra-long separation zone

Request for a quote

MEGA-METAL D.O.O.

Slovenia

We provide our customers with the highest quality products. For that purpose alone, our team of grinders grinds and prepares the products for the next phase of work, which is inspection.

Request for a quote

POLIBRAS S.A.

Portugal

For Portable Machines Diameters: 115mm to 230mm

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

The Kuhlmeyer ZBS Twin Belt Grinding Machine is built for the roughing and finishing on welded edges, corners and surfaces on flat and mid-size workpieces out of steel, stainless steel, and aluminium, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft – manufacturing, round bins, cylinders, heaters etc.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Grinding is an abrasive manufacturing process for processing surfaces with abrasives. The result is metallically pure surfaces free of residues (further processing) and uniform micrographs with high dimensional and shape accuracy and low waviness/roughness. — Lissmac SMW535: max. width 1250mm (grinding, satin finishing and highly decorative processing in one operation) — Kuhlmeyer type ZBS3: max. 4000 x 750 mm — Metallkraft MBSM 2000 ZB: max. 2000 x 750 mm

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

Cutting, deburring and grinding operations, which are generally carried out with manual operations, are problematic in standardization and very risky in terms of HSSE. With robotic projects, we obtain the most precise results in a safe way.

Request for a quote

ASSFALG GMBH

Germany

The Neutrix is a small, light-weight and portable electrode grinding machine which is able to centrically grind in longitudinal direction, providing reproducible quality cuts of tungsten electrodes. Electrode diameters from Ø1-4mm can be reground. Only 0.3mm is removed from the grinding electrode during each grinding process. A stand can be mounted for use in the workshop. The point angle can be set gradually from 15-180°. The grinding dust is collected in an integrated filter cassette. The speed can be regulated for an optimal grinding speed. A special collet can be used to grind tungsten electrodes with a length of up to 15mm. The diamond grinding disc can be used three times through an eccentric disc. The grinding process can be observed through a window. The grinding pressure should be used to prevent the electrodes from glowing and thereby avoid early wear to the diamond disc.

Request for a quoteResults for

Grinding - Import exportNumber of results

382 ProductsCountries

Company type

Category

- Grinding - machine tools (68)

- Crushing and grinding machinery (67)

- Grinding - steels and metals (28)

- Adjustment - machine tools (27)

- Paint mixers and grinding machines (23)

- Machine tools, metal machining - parts and accessories (12)

- Flour milling - machinery and equipment (9)

- Food Industry - Machines & Equipment (9)

- Abrasive discs (6)

- Broaches - machine tools (6)

- Ceramics, industrial (5)

- Cutting - steels and metals (5)

- Abrasives, mechanical (4)

- Diesel engines (4)

- Finishing of surfaces - machinery (4)

- Gears (4)

- Blades and knives, industrial (3)

- Industrial cutting machine tools (3)

- Metallurgy and iron and steel industry - machinery and installations (3)

- Planing lathes, automatic (3)