- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding wheel

Results for

Grinding wheel - Import export

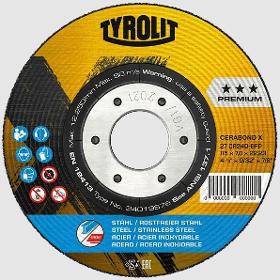

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit's rough grinding wheels meet advanced economic requirements with high stock removal rates, ease of handling, and long life. Our innovative wheels ensure optimal results in both standard and special applications. In steel working, demands for better standing times, higher stock removal, and shorter machining are crucial. The CERABOND X range, with high-grade ceramic grain and innovative bond structure, meets these challenges, excelling on hard steel types and large diameters for economical processes and excellent results. Enhanced Safety and Comfort VIBSTAR reduces vibration by up to 50%, counteracting occupational diseases. SILENTIO reduces noise by 10 decibels, preventing physical damage and increasing comfort. "Comfort Start" technology ensures optimal performance from the start. High-Quality Grinding Wheels Tyrolit’s 1F80 range for straight grinders offers low-vibration work with high stock removal rates on steel, stainless steel, nonferrous metals, and cast iron.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers a comprehensive portfolio of bench grinding wheels for grinding various steels as well as tungsten carbide, cast iron and nonferrous metals. The assortment is additionally complemented by a selection of whetting and polishing wheels to guarantee permanently sharp tool edges. Vitrified-bonded bench grinding wheels are mainly used in workshops and repair stores. They can be universally used for grinding and sharpening various components. The coordinated specifications allow a wide range of applications from coarse to fine grinding. Whetting and polishing wheels from Tyrolit Tyrolit whetting and polishing wheels are particularly elastic and easy to true. Due to their structure, they generate the finest surfaces in the shortest possible time. At the recommended speed, they offer long tool lives and impressively cool grinding to maintain the cutting ability of your tools.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Diamond grinding tools with VIB-Star core for technical ceramic components. Diamond grinding tools with cushioning plastic core system for machining very hard materials and technical ceramic components. Straight diamond grinding tools in vitrified bond for the machining of ceramic components require special damping, thus VIBSTAR is only available in certain dimensions on request. Damping + low weight Better surface finishes Longer lifetime Improved grinding ratio

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In precision grinding, maintaining tight tolerances and perfect surface structures is crucial. The demands in this area have increased, challenging both grinding tool manufacturers and producers. Tyrolit meets these requirements through innovations in precision grinding wheels, distinguished by extensive process know-how and pioneering consulting services. We serve a wide range of industries, including tool manufacturing, automotive, steel, turbine, and medical technology, always adhering to the principle: accuracy is key! Tyrolit offers standardized application technology advice and process support at the highest level. Our expert team, with years of experience, provides constant support. Employees across various countries are closely linked with our headquarters in Austria, ensuring qualified technical support for all precision grinding applications, such as external and internal cylindrical grinding, surface and creep feed grinding, or honing.

Request for a quote

MONGIN

France

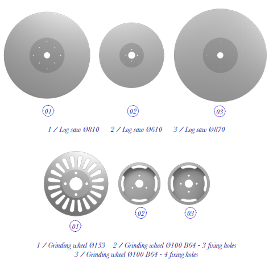

TYPE OF MACHINES : PERINI, PCMC, FUTURA, ... Depending on your converting process, the hardness and abrasivness of your products, we manufacture log-saws : Ø610 / Ø810 / Ø870. Standard bores : 68.26 / 82.55 mm. Short and long bevel : 190 / 230 mm. To obtain a clean and precise cut with an automatic sharpenning, we supply grinding wheels adapted to your machines. 1 / Log saw Ø810 2 / Log saw Ø610 3 / Log saw Ø870 1 / Grinding wheel Ø153 2 / Grinding wheel Ø100 B64 - 3 fixing holes 3 / Grinding wheel Ø100 B64 - 4 fixing holes

Request for a quote

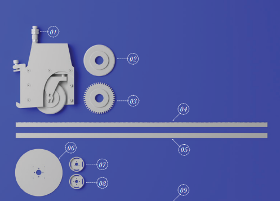

MONGIN

France

Paper core cutting N°1 - Pneumatic knife holder N°2 - Crush knife N°3 - Perforating knife Precutting blade for rewinder machine N°4 - Precutting knife N°5 - Counter precutting knife Blades for transversal cutting machine N°6 - Log saw Ø610 N°7 - Grind wheel B64 - 3 fixation holes N°8 - Grind wheel B64 - 4 fixation holes

Request for a quote

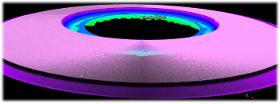

QUELLTECH GMBH

Germany

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product name: Silicon Carbide SIC Nanopowder 90% Place of Origin: China Application: refractory materials Shape: Powder Material: silicon carbide Chemical Composition: Si2O3 Color: Black SiO2: 90%min Usage: Metallurgy Deoxidizer Package: 1 Ton/bag Payment: L/C T/T Supply Ability: 1000 Ton/Tons per Week Lead Time:15-30days Port of shipment:Xiamen,China Applications 1.metallurgical deoxidizer 2.high temperature resistant materials 3.as abrasive,abrasive tools can be used to such as grinding wheels,whetstones,grinding head, sand tile etc Advantages 1.corrosion resistance,high strength,high hardness, 2.good wear-resisting performance,resist to shock 3.stable chemical performance,high thermal conductivity,high resistant temperature

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit leads in grinding wheels for surface and creep feed grinding, especially in highly porous wheels. Our products' high porosity and low hardness ensure maximum cutting ability and removal rates, even on hard materials. This market leadership is due to the intelligent design of our grinding wheels, tailored to material and workpiece geometry for tight tolerances and perfect surface finish. Grain type, grit size, grade, bond, and structure are adjusted for maximum precision and efficiency. Tyrolit offers a broad range of highly efficient grinding wheels for surface and creep feed grinding, ideal for the turbine industry. Our highly porous, vitrified-bonded abrasives guarantee long tool life, cool grinding, and increased profile retention. Electroplated wheels, primarily used in the turbine industry, provide excellent profile accuracy and maximum process stability, resulting in precise grinding results and lower component costs.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Metal-bonded grinding tools for flute grinding With the STARTEC XP-P+ product line, TYROLIT defines a new performance level for the flute grinding of tungsten carbide cutting tools. Two different diamond qualities and the innovative bond structure lead either to significantly reduced grinding forces or to a major increase in profile retention. The precision of the machined tools remains at the usual high level. Increased feed speed Easy profiling Extended dressing intervals

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The choice of the right serrated grinding wheel for grinding knives, scissors, tweezers, pliers, surgical instruments, etc. with the most suitable teeth and the highest quality standards must be determined on a customer-specific basis depending on the intended use. The base body of the serrated grinding wheel is made of aluminum. A coating is applied to the aluminum body, into which the teeth are then inserted depending on the profile shape according to the intended use. With our many years of experience, we would be happy to advise you by telephone or on site regarding a high-quality and cost-effective design of a serrated grinding wheel for your process.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

During pendulum grinding, the Tyrolit grinding wheel moves over the workpiece at a high feed rate. The cast material is processed during the stroke movements, both in synchronised and counter-rotation. Tyrolit pendulum discs are suitable for almost all pendulum grinding machines and deliver the best results, for example when grinding and fettling heavy cast workpieces or metal blocks. The high-quality Tyrolit grinding discs for pendulum grinding are the result of decades of expertise in the development of grinding tools. They significantly increase the efficiency of manual machining of cast workpieces. Zirconium aluminium oxide is frequently used in the abrasive mixtures, which enables shorter grinding times, higher stock removal rates and longer tool life. Advantages of Tyrolit grinding discs: . Less effort required due to high cutting ability . Customised product . Maximum safety for manual sanding work

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Grinding wheels in elastic bond for the centreless grinding of taper rollers For the centreless grinding of taper rollers, a steel profiled regulating wheel is used. A certain elasticity of the grinding wheel is required so that the rollers can still be operated safely. The Tyrolit centreless wheel in elastic bond has proven highly effective. Good profile retention and lifetime Good coefficient of friction

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In high-pressure grinding, the quality of the grinding wheel is crucial for the process result. It determines whether economical snagging of steel can meet technological requirements. Tyrolit's high-performance grinding wheels are designed to quickly and precisely achieve the required quality for further processing, supporting the production process. Snagging is the most common process for plastering semi-finished products. Our tools ensure high process quality, targeted and controllable stock removal, high production output, and consistent surface quality. They also guarantee high economic efficiency, easy handling, and low fault susceptibility. The SECUR line abrasives demonstrate the capabilities of our product range in high-pressure grinding. Many steel grades have surface defects, scales, and decarburization zones after continuous casting, which must be efficiently fettled before rolling mill processing.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

External cylindrical grinding is essential for achieving optimum surface finishes on workpieces like camshafts, crankshafts, and transmission shafts. It's used on various materials, including unalloyed, low-alloyed, and high-alloyed steels, HSS, tungsten carbide, industrial ceramics, and cast metals. The key to selecting the right tool lies in matching the grinding wheel to the specific requirements of the grinding application. This involves considering workpiece properties, tool, machine, settings, cooling lubricant, and dressing technology. Our high-quality tools and consulting services ensure optimal process parameters. Tyrolit offers a wide range of high-quality grinding tools for various applications and materials. We provide vitrified-bonded conventional wheels with different grains for specific materials, and resin-bonded high-performance tools made of CBN or diamond with our special bond system. The VIB STAR system reduces vibration for a smooth grinding process.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our experts continually innovate and optimize our range of abrasives, making Tyrolit a trusted partner in the automotive industry and other sectors requiring precise gear grinding. We offer a comprehensive assortment of grinding wheels, cup wheels, and worm grinding wheels for generating, bevel gear, and profile grinding. Generating gear grinding uses a worm grinding wheel to continuously grind the desired profile into the workpiece. Unlike this, profile gear grinding machines each gear tooth individually, suitable for large gears. Tyrolit's vitrified-bonded profile grinding wheels have set industry standards, delivering exceptional cost-efficiency, process stability, and finish quality for gears of all sizes. With increased quality requirements, hard-fine machining of gears is essential. Tyrolit's special cup wheel line for bevel gears ensures exact topographies and pitches, offering high productivity, low thermal load, and maximum profile retention.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit centerless grinding wheels can grind workpieces from a few millimeters to several meters in length with maximum precision and cost-effectiveness, ideal for large series of identical parts. Centerless grinding wheels are notably thick compared to their diameter. Special pressing processes, adapted specifications, and sometimes split grinding wheels ensure homogeneous density distribution. Tyrolit offers a complete assortment of grinding wheels, regulating wheels, and dressing tools. Continuous product development guarantees high stock removal, tight tolerances, and fine surface results. Resin-bonded CBN grinding tools with a fiber-reinforced composite carrier body offer up to 80 percent less weight and better absorption properties, enhancing grinding results and tool life. Vitrified-bonded wheels use innovative sintering technology to prevent abrasive grain breakage. Lightweight diamond wheels are available for centerless through-feed grinding, gentle on machine spindles.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In precision manufacturing, demands on surface quality and component accuracy are continuously rising. Tyrolit's first-class abrasives ensure precision and functionality in products across all industries, such as watchmaking, eyewear or medical technology. Tyrolit's product portfolio guarantees high-quality machining of components with extremely narrow tolerances, whether for individual pieces or mass production. Our tools meet the most demanding dimensional tolerances. In the electronics industry, we supply cool-grinding diamond ring wheels with special bonds for wafer machining and long-lasting electroplated diamond grinding points for electronic components. The watch and eyewear industries rely on our elastic bonded grinding and polishing tools for precision mechanics components, ideal for deburring, fine grinding and polishing. For medical products we offer vitrified and resin-bonded grinding tools for knee and hip joints and silicon carbide wheels for pointing hypodermic needles.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit serves industries demanding precision and efficiency in double side face grinding. We offer tools that meet the highest standards for precision, performance, and efficiency. With years of experience and innovation, we guarantee the production of plane-parallel functional surfaces of the highest quality without thermal surface damage, even for large grinding allowances and high stock removal volumes. Our tools help achieve the tightest tolerances. Our resin-bonded grinding wheels enable efficient generation of functional surfaces with high evenness and quality. Both face sides can be machined simultaneously, or one side at a time using wheels, segments, rings, or cup wheels. These abrasives offer constant grinding properties, long service life, and a cool grinding finish. Tyrolit also offers diamond grinding tools for ceramic components. Tyrolit's double side face grinding tools combine precision with efficiency. Our experts can help optimize your processes.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our portfolio includes first-class cut-off wheels, grinding wheels, and cup wheels designed for petrol saws, hand-held machines, and railgrinders. These tools excel in high humidity, extreme cold, and temperature fluctuations, and when grinding long track sections. As rail requirements increase, new harder materials are used. Machining these materials is challenging, requiring precision and special know-how, making Tyrolit a leader in rail maintenance cutting and grinding. Our cut-off wheels are designed for aggressiveness and durability, using zirconia alumina grain for easy cutting and enhanced performance. Special grinding wheels for preventive and corrective grinding of long sections ensure the best surface results, lower noise emissions, and longer rail life. Tyrolit wheels also handle repair and cleaning, meeting advanced requirements for cost-efficiency, high stock removal, easy handling, and long wheel life.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

An efficiently sharpened saw blade is essential for productive and safe work processes. Tyrolit offers an extensive range of grinding tools for various saw blades, including chain saws, circular saws, band saws, and gang saws. Our abrasives are precisely matched to different grinding machines and tooth pitches for optimal sharpening results, featuring vitrified-bonded grinding wheels and resin-bonded diamond and CBN wheels for special applications. Tyrolit’s decades of experience are evident in our tools' grit qualities and innovative bond systems, ensuring optimal cutting edge quality. Our grinding tools for automatic chain saw sharpening machines promise extended service life and perfect tooth base radius matching. We also offer resin-bonded diamond wheels for special applications and CBN tools for grinding HSS and high-alloyed steels.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The choice of the right profile sanding wheel for wood sanding must be determined based on the customer’s requirements. Our highly experienced engineers and application technicians would be pleased to advise you by phone or email, on a high quality and cost-effective type of profile sanding wheel of the FAPI-SW series for your process. The profile sanding wheels FAPI-SW are made of the same material used for flap grinding wheels. The significant difference lies in the highly elastic surface of the profile sanding wheel FAPI-SW. This is achieved with individual, disconnected slitted, abrasive cloth packages separated by a large distance to one another and fastened to the wheel hub.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Thanks to many years of experience in steel and metal processing, Tyrolit is a global leader in the steel and foundry industry, particularly in tools for automatic fettling. Modern foundries use high-tech automatic grinding machines, and Tyrolit optimises these processes economically and qualitatively with an attractive range of tools. Tyrolit offers a wide range of tools, including grinding rings, grinding segments, edge-stable resin-bonded grinding wheels and diamond cutting wheels for grey and nodular cast iron. The use of diamond enables a considerable increase in performance. Application engineers provide support in finding efficient solutions, for example when combining diamond and conventional tools. . High economic efficiency . Above-average tool life . Highest surface quality . Reduced noise and dust emissions . Clean cutting quality . Maximum product safety

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers top-quality wheel brushes for optimum weld seam processing and fast cleaning of pipe connections. Whether using an angle grinder, straight grinder or grinding block, our wheel brushes make work easier. Our round brushes for stainless steel and steel are available in various wire types and are ideal for removing rust, scale and concrete residue. The knotted wheel brushes offer additional efficiency. Tyrolit offers the Premium Pipeliner Wheel Brush especially for pipeline construction. Wheel brushes for straight grinders and sanding blocks Tyrolit also offers wheel brushes for bench sanders and straight sanders. These brushes, available in different versions for steel, stainless steel and non-ferrous metals, are ideal for hard-to-reach areas. They are available with crimped wire for derusting and cleaning and with knotted wire for weld seam processing.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide polyurethane lamellae are attached in precisely established spacing while plastic foam lamellae are attached in the spaces between them to the aluminium hub of the frequency damped contact wheel FAPI-KS/V FREQUENCY DAMPED. The height of the coating resp. the length of the polyurethane and plastic foam lamellae can be varied depending on the application (standard: 25 mm). The positioning of the lamellae dampens the howling sounds in the upper frequency range in the contact wheel coating during grinding so that they are no longer audible to the human ear. The contact wheel FAPI-PUS/KS frequency damped achieves a significant reduction of the noise level in the workplace and so contributes its share to work safety. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS/KS is an extremely soft version of a contact wheel with a polyurethane foam and plastic foam lamella coating. The overall height of the coating must also be selected based on the respective application. The alternating polyurethane and plastic foam lamellae make the contact wheel extremely soft and particularly adaptable. In practice, this contact wheel is used mainly for the finishing of strongly cambered or rounded workpieces. Because of the different material densities and the spacing between the lamellae heat dissipates very well during the grinding process. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteResults for

Grinding wheel - Import exportNumber of results

90 ProductsCountries

Company type

Category

- Grinding - machine tools (20)

- Machine tools, metal machining - parts and accessories (7)

- Abrasive discs (6)

- Adjustment - machine tools (5)

- Industrial tools (4)

- Paint mixers and grinding machines (4)

- Abrasives, mechanical (3)

- Aluminium alloys (3)

- Casting, steel (3)

- Diamond tools (2)

- Balancing machines and systems (2)

- Grinding - steels and metals (2)

- Agriculture - Machines & Equipment (1)

- Cutting - machine tools (1)

- Electric and electronic components - machines for manufacturing (1)

- Foundries, aluminium (1)

- Gears (1)

- Industrial cutting machine tools (1)

- Measurement - Equipment & Instruments (1)

- Measurement equipment and instruments - position and distance (1)