- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding and polishing

Results for

Grinding and polishing - Import export

SINOP SMP

Czech Rep.

Polishing, brushing and grinding of stainless steel Polishing, brushing and grinding of brass Manual grinding with a flexible shaft Manual belt grinding machine for pipes Welded drip trays Dispenser racks

Request for a quote

ALLIED FOR TECH

Poland

We perform grinding mainly on endless belts, as well as with the use of special grinders and hand-held power tools.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Heavy duty polishing and belt grinding jack. For belt linishing, grinding and polishing of surgical instruments, faucets, castings and other work pieces.

Request for a quote

WACHSFABRIK SEGEBERG GMBH

Germany

M-50 is an universal, fast cutting formula of medium fine abrasives with extremely uniform particles that gives an ontstanding polishing action for high temperature machine buffing. M-50 is developed to simplify all common heavy duty buffing, formulated especially for the preparation and the maintenance of Polyester and Epoxy moulds er surfaces. Developed for quick and easy removal of coarse marks and scratches, remaining on the surface after the „wet and dry" sanding procedures. For the final deep gloss finish, OSKAR'S M-100 BUFFING AND POLISHING COMPOUND is recommended. Contains no additives harmful to Polyester gelcoats er Epoxy surfaces. Does not contain silicones or waxes.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

The 72711 belt sander offers all benefits of the 72780 series but with only one side. It is made for heavy duty applications. For sitting or standing operation. Variable cutting speeds from 900 to 2,800 Rpm. Optionally with frequency converter.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In precision manufacturing, demands on surface quality and component accuracy are continuously rising. Tyrolit's first-class abrasives ensure precision and functionality in products across all industries, such as watchmaking, eyewear or medical technology. Tyrolit's product portfolio guarantees high-quality machining of components with extremely narrow tolerances, whether for individual pieces or mass production. Our tools meet the most demanding dimensional tolerances. In the electronics industry, we supply cool-grinding diamond ring wheels with special bonds for wafer machining and long-lasting electroplated diamond grinding points for electronic components. The watch and eyewear industries rely on our elastic bonded grinding and polishing tools for precision mechanics components, ideal for deburring, fine grinding and polishing. For medical products we offer vitrified and resin-bonded grinding tools for knee and hip joints and silicon carbide wheels for pointing hypodermic needles.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers a comprehensive portfolio of bench grinding wheels for grinding various steels as well as tungsten carbide, cast iron and nonferrous metals. The assortment is additionally complemented by a selection of whetting and polishing wheels to guarantee permanently sharp tool edges. Vitrified-bonded bench grinding wheels are mainly used in workshops and repair stores. They can be universally used for grinding and sharpening various components. The coordinated specifications allow a wide range of applications from coarse to fine grinding. Whetting and polishing wheels from Tyrolit Tyrolit whetting and polishing wheels are particularly elastic and easy to true. Due to their structure, they generate the finest surfaces in the shortest possible time. At the recommended speed, they offer long tool lives and impressively cool grinding to maintain the cutting ability of your tools.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Heavy duty belt sanding and polishing jack for industrial applications. Compact double ended design. Floor standing pedestal. Rapid belt tensioning and tracking. Also for alumimun polishing.

Request for a quote

INGENERIC GMBH

Germany

The use of aspheres and acylinders offers substantial advantages: minimization of aberrations, increase in efficiency, reduction of optical elements and weight of the optical system. With its unique molding technique, INGENERIC combines cost effectiveness with highest serial precision. Molded optics can be structured/curved on one or both sides with a large degree of geometrical freedom and a flexible lateral contour. The lateral dimensions range approximately from 2.0 mm to 5.0 mm. Structures in the sub-millimeter range are feasible. Acylinders with larger dimensions are manufactured by INGENERIC’s well-proven grinding and polishing technology. The dimensions of these large acylinders can reach 60.0 mm in length and 120.0 mm in height. This technology is particularly adept for the manufacture of fused silica optics for applications with high power densities.

Request for a quoteHASPA GMBH

Germany

We also sell abrasives for all kinds of surface treatment: Grinding, roughing, milling, polishing. Special tools upon request. Systems: - M-quick - K-quick - ATAdisc - corundum(Plus) - zirconium (Z) - carboorundum - fleece rounds - felt rounds - super brade Ask for our abrasive catalogue or send us your detailed inquiry.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit divides the floor grinding process into three parts: rough grinding, pre-polishing, and polishing. In the first two steps, material is removed, and in the third phase, the floor gets its final finish. After each stage, chemical agents are used to densify, seal, or finish the floor. Customers receive these chemicals directly from Tyrolit. In rough grinding, material is removed based on the desired final appearance. Tyrolit offers metal bond grinding shoes with different grains. Cracks and pores are repaired with a special chemical filler. In pre-polishing, the floor is ground with ceramic/resin bonded tools to level it. A densifier compacts and hardens the surface, reducing water absorption. In the final polishing phase, the floor is sealed with a "sealer" to protect against liquids, grease, and dirt. Tyrolit's floor grinding chemicals transform drab substrates into robust, resilient floors with a long-lasting and appealing appearance.

Request for a quote

SAMSYS GMBH

Germany

The handling robot ProFeeder Table from EasyRobotics is a perfect assistant for processes in the field of grinding, polishing and deburring. A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as processing times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Request for a quote

SAMSYS GMBH

Germany

The OnRobot force-torque sensor provides accurate force and torque measurement along all 6 axes. This gives you precise control during difficult assembly, polishing, grinding or deburring. In addition, the HEX software offers path recording, force control and special functions for insertion. This reduces the integration time for your production line. Our sensors are suitable for most of the industrial robot arms currently in use. Common applications are polishing, grinding, deburring and assembly. They can also be used for teach-in applications and collision detection. Currently available models: HEX-E – High precision, HEX-H – Low deformation, HEX-E QC, HEX-H QC Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Request for a quote

INGENERIC GMBH

Germany

High-precision Aspheres and Acylinders The use of aspheres and acylinders offers substantial advantages: minimization of aberrations, increase in efficiency, reduction of optical elements and weight of the optical system. With its unique molding technique, INGENERIC combines cost effectiveness with highest serial precision. Molded optics can be structured/curved on one or both sides with a large degree of geometrical freedom and a flexible lateral contour. The lateral dimensions range approximately from 2.0 mm to 5.0 mm. Structures in the sub-millimeter range are feasible. Acylinders with larger dimensions are manufactured by INGENERIC’s well-proven grinding and polishing technology. The dimensions of these large acylinders can reach 60.0 mm in length and 120.0 mm in height. This technology is particularly adept for the manufacture of fused silica optics for applications with high power densities. Advantages superior image quality freedom of design free form surfaces integrated...

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NIRO PRÄZISIONSTECHNIK GMBH

Germany

Probably no other material offers such hygienic working conditions as stainless steel: no product build-up, easy to clean, acid-resistant. As a specialist in the machining and processing of stainless steel, we have developed professional work tables that meet the highest hygiene requirements. We manufacture individual items for ambitious hunters and anglers as well as small series for the commercial food industry. We implement your ideas sensibly based on sketches or drawings. For surface designs, we offer you various grinding patterns up to high gloss polishing and an area size of up to 1000 x 2000 mm. All workpieces can be used both indoors and outdoors.

Request for a quote

GRONBACH

Germany

Gronbach manufactures decorative elements for the automotive industry in interior and exterior areas such as trim strips or trim parts made of aluminium, stainless steel and plastic hybrid technology. Functional components and plastic injection molded parts with a focus on fan wheels and turbines are also essential components of our technologies. As a specialist for surface finishing, you have a wide range of colours (anodising, powder coating), noble shapes and surfaces (brushing, grinding, polishing, blasting) and high-quality individualisation (screen printing, pad printing, under-anodising printing, laser engraving, etching techniques) at your disposal. In addition to the production of individual parts and the manufacture of complex assemblies as well as end products, we also offer you as a system supplier the complete project planning for new developments. Our portfolio includes: Automotive door sills Interior visible parts, e.g. side applications, decorative panels and...

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA POR is porous and has a smooth surface structure. The product is characterized by a high stability, pressure-resistance and a long-term heat resistance of over 190°C. It is especially suitable for moulds with fine and complex structures. The good air permeability leads to a uniform stretching of the foil in the process of thermoforming. With this innovative product the annoying drilling of vacuum holes becomes obsolete and thus no visible markings are left on the thermoformed foil. Larger dimensions can be achieved by screw connections. Longer and wider dimensions by gluing. ALWA POR is easily machinable: Sawing, drilling, grinding, polishing. It also remains porous after polishing. ALWA POR is especially suitable for vacuum thermoforming and vacuum forming and is additionally suitable for - aeration of aquaria, fishponds and sewage treatment plants, - venting of injection moulds and blow moulds, - any proceedings of hot steam or water steam processing, - vacuum clamping

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Cleaning discs FAPI-CLEAN provide very good results when grinding and cleaning metal, stainless steel, wood or plastic and can therefore be used as a preliminary stage for grinding/polishing. We will be happy to advise you by telephone or at your site whether the use of cleaning discs FAPI-CLEAN also makes sense in your company for your processes. Construction Cleaning discs FAPI-CLEAN consist of knitted nylon threads which have been soaked in synthetic resin and gently cured. They are available on fabric plates and for use on straight and shaft grinders. Applications The cleaning discs are suitable for cleaning and polishing all surfaces. Scratch-free removal of paint, rust, scale and welding spots from metal Cleaning wood and plastic Remove paint from wood Free stainless steel from blue colouring Dimensions For cleaning discs FAPI-CLEAN the principle applies that they may only be used in conjunction with a clamping shank. Notice: For cleaning discs, the principle applies...

Request for a quote

SPIROL

Germany

SPIROL specializes in the custom manufacturing of tightly toleranced Precision Shims, Specialty Washers and Thin Spacers. SPIROL produces Shims custom-made to customer specifications in thicknesses ranging from 0.02mm up to 9.5mm (.001" up to .375") using a variety of stamping methods, machining processes and laser technology to meet your specific lead time and total cost considerations. Whether a project is for prototype, short run or long-term requirements, SPIROL has a solution to minimize costs by controlling - or even eliminating - tooling costs. In addition to having flexibility in our primary operations, SPIROL also performs most secondary processes in-house including heat treating, grinding, lapping, high speed polishing deburring, finishing and passivation.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit's flap wheels incorporate decades of expertise from a leading manufacturer of grinding tools. Designed for high performance, efficiency, and cost-effectiveness, each flap wheel demonstrates our commitment to excellence. Our premium products for angle grinders are suitable for general grinding, cleaning, finishing, and polishing uneven or curved surfaces made of steel, non-ferrous metals, and wood. Their flexibility allows optimal contour adaptation. One key advantage is the constant wear pattern over the entire lifetime, ensuring consistently high-quality surface finishes. Our flap wheels offer a range of high-quality products for efficiently removing weld seams, scratches, and oxidation residues, and for perfect surface pre-treatment. Conclusion: Tyrolit's flap wheels for angle grinders are the top choice for machining steel, non-ferrous metals, and wood when high-quality fine grinding is required. Choose Tyrolit for superior results.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ball Mill /Beads / Grinding Media is made of good material and used advanced technology, which is suitable for any kinds of mills such as sand mill, attrition-mill, vibratory mill, ball mill and so on. It is used to grind and disperse the material of painting, dye,ink, titanium, electronic battery material, rare-earth material, nonmetal ore, calcium, pesticide, food stuff and medicine etc..Because of its high density, toughness and hardness, zirconium grinding media’s efficiency is much better than traditional ones.The high wear-resistant zirconium grinding media can not only prevent materials from being contaminated, but also prevent chemical erosion that affects its working life Sizes Ømm of the Zirconia ball mill grinding media : - 0.2-3mm,5mm,10mm,15mm,20mm Usage of the Zirconia ball mill grinding media: - Ø0.5-3mm Grinding ball use in sand mill - Ø5-20mm Grinding ball use in mix mill and ball mill - OverØ20mm Grinding ball use in ball mill

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

OEM Forging Auto Parts OEM Forging Auto Parts Manufacturer Process precision forging+ blasting+ cnc machining (https//www.frimaparts.com/precisionmachiningparts2/) Material Aluminum , Brass (https//www.frimaparts.com/brassforgingparts/) , carbon steel, stainless steel, iron Machining turning, milling, drilling, grinding, threading, CNC Finishing sand blasting, polishing, plating, acid treatment, anodizing, coating Design customized samples or drawings are accepted Weight range 0.1100KG Packaging paper carton + bubble bag Delivery time tooling/sample within 4 weeks, batch order within 4 weeks. Inspection all the products are strictly inspected by QC. We develop custom products for clients all over the world, such as 3D Robotics, Nvidia, Smart Systems and so on. We are experienced in many processes, such as stamping (deep drawing, bending), cutting (pipe cutting, profile cutting,

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

For light grinding, polishing and milling work. Length: 1.500 mm Shaft core Ø: 6 mm max. Speed: 30.000 rpm Connection to Machine: M10 x 30 threaded Connection Connection to handpiece: square small (5mm)

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Milling, grinding, brushing, polishing, filing – and all with a single device! This all-rounder is suitable for use in almost all sectors of industry The best results are achieved through digital sensorless control electronics. This ensures: * Consistently high torque at any speed between 5,000 and 15,000 rev/min. * Constant speeds at different loads. * Retrieval of power reserves: at maximum load a remarkable peak power of 1.5 kW. Above this the machine is shut down by the overload protection. * No pulsation in the low speed range. * Work results in smoother surfaces. Low maintenance costs and no unnecessary downtime * The motor is protected from overloading by an automatic cut-out. * Automatic cut-out if wear occurs to the carbon brushes. * Fully encapsulated sensorless electronics cannot be clogged with metallic particles. * Electrical surge protection prevents current peaks and protects the motor. Delivers the highest attainable degree of occupational safety and comfort.

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

The best MB20 that we have ever had. What‘s new? • Higher speed of up to 34,000 rpm for finer, more precise work. • The motor is protected from overloading by an automatic cut-out. • Restart protection provides a high degree of safety. • Prolonged motor life through optimum dust protection. Inexpensive to purchase and maintain. Safe to operate. • Cost-effective universal motor in a sturdy plastic shell. • Automatic cut-out if wear occurs to the carbon brushes • Soft start. • Degree of protection: IP 20, Protection class: II Specifically designed for versatile use in mould making • Constant speed under load. • Uses various quick-change hand pieces for milling, grinding, polishing, brushing and filing. • The machine can be operated standing upright or suspended from a hook.

Request for a quote

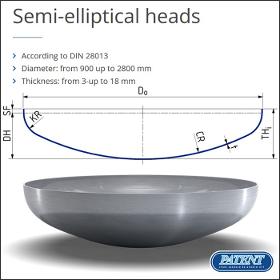

PATENT KFT.

Hungary

Elliptical heads (DIN28011) can be manufactured in stainless steel only. Flanging, bevelling, surface treatment, grinding and polishing, pickling, surface protection and nozzle cut-outs according to customers' requirements. Contact us, ask for a quote! Our staff will be happy to provide you with full information. Acronyms of the technical data: D = outer bottom diameter R = Dish radius s = Wall thickness H = Overall internal height without straight flange h = Height of straight flange

Request for a quoteResults for

Grinding and polishing - Import exportNumber of results

51 ProductsCountries

Company type

Category

- Polishing - machine tools (7)

- Grinding - machine tools (6)

- Adjustment - machine tools (4)

- Grinding - steels and metals (3)

- Cold rolled sections (2)

- Metallurgy and iron and steel industry - machinery and installations (2)

- Robotics (2)

- Abrasives, mechanical (1)

- Assembly robots (1)

- Brushes and paint brushes (1)

- Ceramics, industrial (1)

- Cleaning machines, industrial (1)

- Finishing of surfaces - machinery (1)

- Industrial resin coatings (1)

- Laser - cutting and welding machines (1)

- Locks, bolts and keys (1)

- Metallurgy - machinery and installations (1)

- Metalworking - portable power tools (1)

- Optical measuring equipment (1)

- Plastic material processing (1)