- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gasket sheets

Results for

Gasket sheets - Import export

GAMBIT LUBAWKA SP. Z O.O.

Poland

GAMBIT AF series asbestos-free gasket sheets are state-of-the-art materials for technical sealing of various media, and for application in a broad range of temperatures and pressures. These products are composites of top quality aramide fibres, specially composed inorganic fibres, and fillers, as well as elastomers selected for specific working conditions. Highly specialised calendering process of sheets, meeting the requirements of ISO-9001, guarantees high and stable quality. Technical parameters of GAMBIT AF sheets meet the requirements for the majority of applications. Wherever specific working conditions prevent using GAMBIT AF sheets we offer sheets based on expanded graphite, expanded vermiculite, or PTFE. All these products offer the highest level of quality and reliability.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Formstable biaxially expanded ePTFE sheets or die cutted gaskets Characteristics Excellent adaption High blow-out resistance No cold flow Chemically inert Technical parameters pH 0 - 14 Temperature: t = -200 … +280 °C Pressure: p = Vacuum … 200 bar Density: 0,95 g/cm 3 (D11 - 0,7 g/cm 3) Minimum Surface pressure: VU (40 bar; 0,01) = 26 Mpa Maximum Surface Pressure: VO = 150 Mpa Minimum surface pressure in operation: BU < 5 Mpa Cold upset compression value: KSW = 40 % Remaining Thickness after compression approx. 15 % higher than values of D11. Main application Flanges Vessels Lids Joints Narrow flanges Bigger uneveness Tension sensitive components (e.g. sight glasses) Suitable for Chemical industry Food industry Maintenance Approvals DIN 28090-2 TA Luft 1,5 · 10 -8 mbar · l/(s·m) @ 250 °C FDA conformity EG 1935:2004 EU 10/2011 Form of delivery Sheet dimension: 1,000 x 1,100 mm and 1,500 x 1,500 mm Sheet gaskets thicknesses: 0.5 / 1.0 / 1.5 / 2.0 / 3.0 / 4.0 / 5.0...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

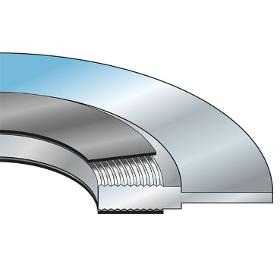

Sheet gasket from expanded graphite with multilayer stainless steel foil reinforcement Characteristics Premium graphite gasket, reinforced by 0.05 mm multilayer stainless steel carriers in an adhesive free sandwich compound with the graphite layers. Purity 99.8 % High blow out safety and mechanical strength Practically no cold flow or creep under temperature Non hardening Excellent in use at cycling temperatures Reduced Emissions due to high sealability Built in safety against assembly and operational problems. Technical parameters pH 0 - 14 Temperature: t = -250 … +550 °C, in oxidizing atmosphere 450 °C Pressure: p = 250 bar Main application Highly recognised as problem solving gasket material in all industries with higher pressures and temperatures and the demand on operation safety and sealability Suitable for In all industries Approvals BAM DVGW TA Luft FIRE SAFE API 607 Variant Economic grade alternative D 5.3 with multiple 0.05 mm stainless steel foil...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High temperatur sheet gasket from expanded graphite with stainless steel foil reinforcement Characteristics One layer of 0.05 mm stainless steel carrier (3 mm thickness 2 layers) with graphite on both sides fixed by a special only 10 µm thick adhesive coating. Purity 98 % Practically no cold flow or creep under temperature Excellent in use at cycling temperatures Very good sealability even at low gasket stress. Technical parameters pH 0 - 14 Temperature: t = -250 … +550 °C, in oxidizing atmosphere 450 °C Pressure: p = 40 bar Main application Suitable for sensitive flange connections Housings of pumps and fittings Suitable for In all industries Approvals BAM DVGW Variant Economic grade alternative D 5.2 with 0.05 mm stainless steel foil reinforcement Form of delivery Gasket sheet size of 1,000 x 1,000 mm in der Dicke 0.55 / 0.75 / 1.0 / 1.5 / 2.0 / 3.0 mm or cut gaskets according to drawing, or EN and international Standards. Special dimensions on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Sheet gasket from expanded graphite with tanged stainless steel foil reinforcement Characteristics Graphite gasket reinforced with a 0.1 mm tanged stainless steel insert and a purity of 98 %. Practically no cold flow or creep under temperature Excellent in use at cycling temperatures High blow out safety Built in safety against assembly and operational problems. Technical parameters pH 0 - 14 Temperature: t = -250 … +550 °C, in oxidizing atmosphere 450 °C Pressure: p = 100 bar Main application Robust graphite gasket applicable in all industries and as well approved to seal older equipment. Suitable for In all industries Approvals BAM DVGW FIRESAFE Variant Economic grade alternative D 5.1 in 0.1 mm 316 tanged stainless steel sheet reinforcement Form of delivery Gasket sheet size of 1,000 x 1,000 mm in thickness of 1.5 / 2.0 /3.0 mm or cut gaskets according to drawing, or EN and international Standards. Special dimensions on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Gasket Sheet of Expanded Graphite, both sides with impregnation Characteristics Soft and extremely adaptable non reinforced graphite sheet with a purity of 99.85 %. Special coating on both sides raises sealabilty. Practically no cold flow or creep under temperature. Non hardening Excellent in use at cycling temperatures Excellent sealability even at low gasket stress. Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C, in oxidizing atmosphere 450 °C Pressure: p = 40 bar Main application Sensitive Flange connections like sight glasses, glass- or glass lined flanges in all industries. Suitable for In all industries Approvals BAM DVGW KTW Variant Economic grade alternative D 5.0 on request. Form of delivery Gasket sheet size of 1,000 x 1,000 mm in thickness of 1.0 / 1.5 / 2.0 mm or cut gaskets according to drawing, or EN and international Standards Special dimensions on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

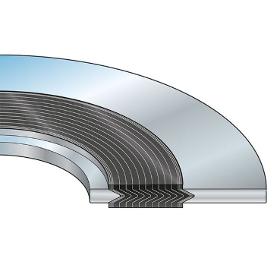

High Temperature Gasket of Expanded Flexible Graphite with Stretchmetal Characteristics Expanded graphite sheet gasket with Stainless Steel stretch metal reinforcement and a purity of 99 %. Practically no cold flow or creep under temperature. Non hardening Excellent in use with cycling temperatures. Blow out safe due to 3 dimensional reinforcement matrixes Optimized transfer of sealing stress Safe use even with small sealing width Minimized risk of separation known from multilayer reinforced gasket sheets. Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C, n oxidizing atmosphere +450 °C Pressure: p = 200 bar Main application Universal use as problem solver in all industries when demanding higher operation safety and sealability especially in older plant equipment. Suitable for Chemical industry Petrochemical plants Pharmaceutical industry Power plant technology Paper industry Sugar industry Approvals DVGW BAM TA Luft FIRE SAFE API 607 on request Form of...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 5 Prophit High Temperature Gasket of Expanded Flexible Graphite with and without reinforcements Characteristics Temperature range in inert environment up to +3000 °C (attention: reinforcement inserts cause temp limits) Permanent elasticity, resilience approx. 10 % Non ageing - does not contain binding compounds High pressure resistance Radiation resistance and excellent media resistance Main application Flanges Sight glasses Valve bonnets Pipe flanges Suitable for Chemical industry Petrochemical refineries and steam production Pharmaceutical industry Power plant technology Paper industry Sugar industry Form of delivery Sheets or custom die cut rings With inner or/and outer crimp: mat. 1.4571 0.15 mm thick, seamless pressed Other materials and designs on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % virgin PTFE, modified and filled with Barium sulfate Characteristics Protected against cold flow Excellent recovery Excellent chemical resistance in caustic applications Reduced leakage rates compared to other filled PTFE gaskets under the same gasket stress. Technical parameters pH 0 - 14 Temperature: t = -180 … +230 °C, short term up to 260 °C Pressure: p = 55 bar Article code / Thickness WHITE 08 / 0.8 mm WHITE 10 / 1.0 mm WHITE 15 / 1.5 mm WHITE 20 / 2.0 mm WHITE 30 / 3.0 mm Main application Steel-, Glass-, Ceramic-, glass lined or plastic flanges on pipework Vessel Container Reactors Suitable for Chemical and Petrochemical industry Approvals TA-Luft Form of delivery Gasket sheet size of 1,500 x 1,500 mm in thickness of 0.8/1.0/1.5/2.0/3.0 mm or cut gaskets according to drawing or EN and international Standards, special dimensions on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Modified PTFE reinforced with special silica filler Characteristics Protected against cold flow Excellent recovery Very good in applications with varying temperatures Reduced leakage rates compared to other filled PTFE gaskets under the same gasket stress. Technical parameters pH 0 - 14 Temperature: t = -180 … +230 °C, short term up to 260 °C Pressure: p = 55 bar Article code / Thickness FAWN 05 / 0.5 mm FAWN 10 / 1.0 mm FAWN 15 / 1.5 mm FAWN 20 / 2.0 mm FAWN 30 / 3.0 mm Main application Steel or other metal flanges on pipework Vessel Container Reactors in higher temperature applications. Suitable for Chemical and Petrochemical industry Approvals TA-Luft Form of delivery Gasket sheet size of 1,500 x 1,500 mm in thickness of 0.5 / 1.0 / 1.5 / 2.0 / 3.0 mm or cut gaskets according to drawing, or EN and international Standards, special dimensions on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Static, Sintered PTFE Sheet Gaskets Characteristics Microcellular structured PTFE filled with hollow glass microspheres High sealability even at low gasket stress Minimized cold flow Very good recovery High compressibility and adaptability even at slightly damaged flanges Technical parameters Temperature: t = -180 … +230 °C Pressure: p = 55 bar Article code / Thickness BLUE 05 / 0.5 mm BLUE 08 / 0.8 mm BLUE 10 / 1.0 mm BLUE 15 / 1.5 mm BLUE 20 / 2.0 mm BLUE 30 / 3.0 mm Main application Steel-, Glass-, Ceramic-, glass lined or plastic flanges on pipework Vessel Container Reactors Universally on all tension sensitive equipment flanges. Suitable for Chemical industry Pharmaceutical industry Food industry Approvals DVGW TA Luft FDA EG 1935:2004, EU 10/2011 FDA Variant D3.1 Modified PTFE: Reduced deformation under pressure, better resilience under varying pressure, reduced thermal expansion coefficient (approx. 50 %) D3.2 Glas: Improved compression strength due to glas fiber...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Universal fiber based high pressure gasket Characteristics A perfect selection of gasket material is based on operating conditions like pressure, temperature, media, surface pressure, Nonstick coating assures quick and scaling free disassembling Do not use any surface treatment! Technical parameters Temperature: t = -100 … +200 °C, short term up to 280 °C Pressure: p = 120 bar mainapplication Tube and pipe flanges Vessels Boilers Cylinders Joints Casings Lids Suitable for All Industries Approvals DVGW KTW BAM Form of delivery Sheets 1500 x 1500 mm in thickness of 0.5/0.8/1.0/1.5/2.0/3.0 mm or cut gaskets according to drawing or EN and international Standards Special dimensions and further gasket material styles from recognised manufacturers on request.

Request for a quote

AXON CABLE SAS

France

Addix, a French subsidiary of the axon' group, specialising in elastomer products and offering shapes for connectors. Types of shapes Grommets Interface gaskets O-rings Gasket sheets Protective caps Insulators with inserts Compounds The most common used compounds are : Silicone, fluorinated silicone, Vitax™ (FKM) Aeronautics approved compounds (see the list of approved compounds) Other materials (see our elastomeric chemical properties comparison table) Applications Military Aeromil and space Offshore Industry, ...

Request for a quote

GAMBIT LUBAWKA SP. Z O.O.

Poland

Gambit offers a wide range of high quality fl ange gaskets, meeting various requirements. Different types of fl anges and different chains of dimensions are applied. For fl anges defi ned this way Gambit Lubawka Sp. z o.o. manufactures gaskets according to appropriate norms describing construction and sizes of gaskets. Numbers of these norms are referred to in description of individual types of gaskets. We also manufacture gaskets beyond the chains of dimensions, according to requirements defi ned by a customer. In order to meet our customers’ demands related to various fl ange systems, we manufacture different types of gaskets: 1. GAMSEAL gaskets cut from AF series gasket sheets, 2. GAMBITGRAF gaskets cut from graphite sheets, 3. GAMPROFILE kammprofi le, 4. GAMSPIR® spiral wound gaskets, 5. AZMES gaskets, 6. GAMFLEX metal jacket gaskets.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

For Fast and Economical Instant Manufacturing of Sheet Gaskets Characteristics Fast and flexible solution for a whole range of applications Easy and safe operation Round shapes cutting from 30 up to 1000 mm Suitable for various sheet thicknesses up to 9 mm Also small sized sheet pieces are processable Spare parts on request Version W5FDKS300 simple solution for easy and infrequent use for gaskets with a max outer diameter of 300 mm.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Gasket sheets - Import exportNumber of results

18 ProductsCountries

Company type