- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas separators

Results for

Gas separators - Import export

FAUDI GMBH

Germany

Advantages Certified Gas Separator; maintenance-free operation Area of application For the use at refuelling points of aviation fuel, gasoline and hydrocarbon Flow rate Various filter sizes and the modular design enable any required flow rate. classification number P54 Filter aid - Filtration degree - Medium Kerosene, fuel, hydrocarbon Filter material -

Request for a quoteFAUDI GMBH

Germany

Advantages Certified Gas Separator; maintenance-free operation; for the separation of rough particles Area of application For the use at refuelling points of aviation fuel, gasoline and hydrocarbon Flow rate Various filter sizes and the modular design enable any required flow rate. classification number P55 Filter aid - Filtration degree - Medium Nitrogene, gases Filter material Perforated Plate Cylinder Mesh

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Centrifugal gas separator are among the best components in the protection of your flow measurement accuracy, both custody transfer applications as well as in everyday application process. Application For avoiding measuring errors and damage caused by foreign particles contained in the medium. Reliability • maintenance-free • complete emptying via outlet socket Special features • with automatic float-dearation device, level probe and controled magnatic valve or defined return to the process (orifice) • mandatory for fiscal metering with pump operation in Germany • Bopp & Reuther Messtechnik Centrifugal Gas Separators possess the EWG design approval and are approved for EWG primery approval for fiscal metering Flexibility • DN 25 to 400 • up to 20 mPa ·s • up to 25.000 l/min • up to PN 50

Request for a quote

BORSIG GMBH

Germany

BORSIG offers attractive process solutions for various gas separation applications in the fields of oil and gas production or refinery and process technology, such as BORSIG Hydrogen separation and BORSIG Fuel gas conditioning. This covers the treatment of gas streams for conditioning raw gas flows, recovery of specific components and the improvement of product quality to comply with customer gas specifications. Process concepts can be developed in addition to existing processes or as an alternative to conventional process solutions.

Request for a quoteFAUDI GMBH

Germany

Advantages Absolute separation of liquid particles greater than 10; for the operation under etreme temperature and pressure; minimal pressure loss Area of application For the filtration of natural gas Flow rate Various filter sizes and the modular design enable any required flow rate. classification number P51 Filter aid - Filtration degree - Medium Air, gases Filter material Wired Mesh

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ideal and reliable highflow CO2 pressure reducing valve for use with CO2 gas or liquide. Constructed in brass (C31) and meehanite (C2K32) with stainless steel trim Abrasion and dirt resistant rubber valve seats Dome loading either from inlet line or separate gas supply Stable and noiseless operation Positive gastight shutoff Highflow contoured passages

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Lockable gas springs are commonly used in applications requiring the ability to lock out the stroke in a desired position without the need for external locking mechanisms. This is achieved by a unique piston design that separates the gas and oil chambers of the spring

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HMV is the preferred flame chamber for conducting burn rate and burn resistance tests on automotive interior materials. Its durable stainless steel construction, large glass viewing window, door- mounted burner and lift-off top cover for easy specimen access greatly enhance user convenience. The loading of specimens is simplified with a unique snap-together specimen holder. The optional Automatic Gas Control (AGC) features a digital timer and push-button gas controls that provide automatic or manual flame impingement modes. The Atlas HMV was designed with the user in mind. Worldwide use for qualification of automotive interior materials Stainless steel chamber with removable top Door-mounted burner with flame height adjustment and pilot ignition Stainless steel U-shaped specimen holder with support stand Specimen supporting wire Stopwatch and measurement scale Separate enclosure for gas controls Specimen holder assembly Stainless steel cabinet Specimen support frame Dimensions: 38cm (15'') W x 20cm (8'') D x 38cm (15'') H Weight: 11 kg (28 lbs.) Automatic Gas Control (AGC) System for automated flame impingement and piloted ignition

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

WITH DIGESTER CHAMBER VOLUMES RANGING FROM 200 M3 TO 5.000 M3 The LIPP Universal digester which unlike the KomBio reactor does not have an integrated gas accumulator, is used for larger plants for industry and municipalities. The biogas accumulated is either directed into a KomBio reactor combined with the Universal digester or into a separate gas accumulator. KEY BENEFITS Production of renewable energy and reduction of fossil CO2 emissions Low noise emissions Flexible substrate composition Customisable pumping and stirring technology High functional safety Effective insulation results in low heating requirement Quick construction thanks to on site production Low investment costs Low maintenance and durable Consistent quality worldwide PRODUCT SPECIFICATION MODULAR PLANT CONCEPT The LIPP Universal digester essentially consists of a (Verinox) stainless steel tank with a modular design. Panel heating and insulation are fitted on the outside and are easily accessible.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Separate water easily from your oil and gas streams From bonded fiber to sintered porous media, Porex creates media to separate or filter water from oil and gas streams. Specifically designed for your oil and gas application, our water separation media: Reduce material usage - Porex bonded fiber material products can replace the need for multiple medi layers commonly found in oil/water separation filters. Self support - Filters can be self-supporting and customized into various shapes and sizes. request sample ask an engineer

Request for a quote

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Fine sediment and foam particles in the saturated biogas originating directly from the digestion can make it s way into the pipework system. In order to eliminate sediment accumulation in the pipework an ennox sediment trap can be used. The trap is installed after the reactor directly in the pipework. With a special nozzle at the trap inlet the saturated and contaminated gas is set into a spiral motion. The particulate matter separates from the gas on the side walls and passed into the collection point with the extracted water vapour. Discharge is carried out with a siphon. Additionally a spray and control connection can also be installed.

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Explosionproof/flameproof gas preheater EEx d -ATEX und IECEx zertifiziert In general a cooling down takes place at expansion of gases whilst a heating takes place at compression. Typical gases are carbon monoxide, natural gas and air. The temperature change, which occurs at expansion of gas or gas mixture from a high to low pressure i.e. after a gas pressure control is called Joule-Thomson effect. In order to prevent the effects of Joule-Thomson as icing or condensate separation, the gas will be heated up before expansion. The gas pre heaters are suitable for all kind of gaseous media (i.e. air, natural gas, technical gases, fuel gas) and low flow process applications, suitable for pressures up to 300 bar. The “Cast electric heaters” type flameproof electrical gas pre heaters are certified for use in zone 1 or 2 hazardous area, custom built to meet client specification. The gas pre heater consists of a process tube coil and an electrical heating bundle, casted in aluminium. The process gas flows through the tube coil and is heated by the aluminium block that provides the heat transfer. This indirect electric heating gives an accurate control of the process and eliminates pressure vessel design and associated costs.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS steam generators: - Efficient steam generation in combined heat and power plants - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Performance areas: 1 to 25 baro, 100 to 25,000 kg/h - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives - Single, double or triple version for operation with one, two or three engines with completely separate exhaust gas sections - The APROVIS Controlling System (ACS) is individually adapted to each project and is delivered in the required language - Access to the ACS using a modem enables easy fine-tuning of the system or remote maintenance for swift support if and when discrepancies occur during operation

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina cearmic bar is used when conditions exclude the use of metal, either for chemical reasons or because of excessive temperatures.Their main applications are between 1000 and 1800°C. They may be in directly contact with the medium or may be used as a gas-tight inner sheath to separate the thermocouple from the actual metal protection tube. Ceramic tubes should be mounted in a hanging position above 1200°C to prevent distortion or fracture due to bending stresses. Evenhair-line cracks can lead to contamination of the thermocouple resulting in drift or failure. High purity ceramic strip provide a broad range of engineering properties: High Temperature-Superior Strength-Corrosion Resistance-Thermal & Electrical Insulation along with other specialized characteristics. -Precision Close, Tight Tolerances, -Ceramic Bar & Ceramic Strip machined to customer specifications-Prototype to Production-Intricate ceramic machining -Alumina is widely used in automotive,petro-chemical

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Discover Oxygen gas production with Nitroplace’s superior quality and modern technology. PSA technology is applied in the separation of oxygen gas from compressed air. Thanks to PSA technology, you can produce oxygen gas in the range of 90% – 95% purity at a capacity of 0.5 – 385 Nm3 / h. Please contact us for our alternative products that are less costly, safe and suitable for your needs. Why don’t you produce oxygen on-site with low costs instead of buying oxygen cylinders yourself? Nitroxtec; oxygen generators have the modern technology needed to produce oxygen. Our Oxygen Generators is reliable, sustainable and cost-effective source of oxygen gas with modern PSA technology. Our oxygen generators are used in every sector where oxygen gas is needed. It is a very important option for companies that value sustainability, efficiency and profitability. Nitroxtec; It enables you to become a professional oxygen producer with on-site oxygen generators. Produce the oxygen gas yourself.

Request for a quote

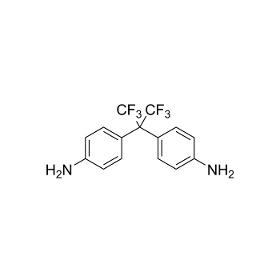

GM CHEMICAL CO., LTD

China

Product Identification Chemical name: 2,2-Bis(4-aminophenyl)hexafluoropropane Synonyms: 6FDAM, BIS-A-AF, 4,4'-(Hexafluoroisopropylidene)dianiline, 6F-DIAMINE CAS No.: 1095-78-9 Molecular formula: C15H12F6N2 Molecular weight: 334.26 Melting point: 195-198 ℃ Specification Appearance: Pale yellow powder Purity: 99.00%min Moisture: 0.10%max Metal ions content: 5 ppm max/EA Package Regular Packing: N.W 25kg/fiber drum Sample Packing: 0.1kg-1kg foil bag Transportation Information Classification: Non dangerous goods HS Code: 2921590090 Status & Application Status: commercial available Application: 1) High performance polymer monomer. 2) Used as a reactant in the crosslinking and stabilization of nanoparticle-filled polymethylpentyne nanocomposite membranes for gas separations. 3) OLED intermediate

Request for a quote

EUROPE ZHAOHAN VACUUM PUMP CO., LTD

Hungary

Closed circulation vacuum system is consisted with liquid ring vacuum pump and compressor, liquid and gas separator tank, heat exchanger, instrument and valves, internal pipeline, and common base plate. The pumped gas enters the liquid ring vacuum pump/compressor from the pump inlet, after compressed by the liquid ring vacuum pump/compressor, the gas will enter to enter the gas-liquid separator together some of the working liquid. Inside the gas-liquid separator, the gas and liquid are separated, and the gas is discharged from the pump outlet, and the working fluid go from the heat exchanger and enter the liquid ring vacuum pump/compressor for recycling.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Technical specifications • Swagelok-screw joints, flange DN 15 PN 40, milk threads according to DIN 11851 PN 10 • accuracy ± 0,2 kg/m³ • reproducibility 0,05 kg/m³ • operating temperature according to design -40°C to +210°C Accessoires Accessoires • electronical transmitter • pre-amplifire • strainer • gas separator • processing peripherals

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Technical specifications • DN 80 - 300 • PN 16 -100 • flow rates 18 - 2400 m³/h • accuracy ± 0,15 % over a reduced flow range ( for viscosities of 0,2 – 0,7 mPa ·s ) • accuracy ± 0,25 - 0,3 for the standard - flow range ( for viscosities of 0,2 – 0,7 mPa ·s ) • operating temperature according to design -190°C to +250°C • for custody transfer admitted Accessoires • electronical Counter • pulse pick-up • strainer • gas separator • processing peripherals

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

For applications in laboratory, medical and engineering, where limited space, monitoring fluid quality and costs play an important role, they provide an ideal, previously not achievable solution. Technical specifications • hose connector • accuracy ± 1 kg/m³ • reproducibility 0,1 kg/m³ • operating temperature 0°C to +70°C • measuring range density 500-1500 kg/m³ • measuring flow 1-6 l/min Accessoires • strainer • gas separator • plug

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Technical specifications • inner threads G1/4” ISO 228, flange DN 10 PN 40, sterile screw joints according toDIN 405 PN 16 • accuracy ± 0,1 kg/m³ • reproducibility 0,05 kg/m³ • operating temperature according to design -40°Cto +150°C • according to design admitted for custody transfer Accessoires • electronical transmitter • preamplifire • strainer • gas separator • processing peripherals

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Technical specification • DN 10 - 65 • PN 16 - 320 • flow rates 0,15 - 120 m³/h • accuracy ± 0,15 % over a reduced flow range ( for viscosities of 0,2 – 0,7 mPa ·s ) • accuracy ± 0,25 - 0,3 for the standard - flow range ( for viscosities of 0,2 – 0,7 mPa ·s ) • operating temperature according to design -196°C to +250°C • for custody transfer admitted Accessoires • electronical Counter • pulse pick-up • strainer • gas separator • processing peripherals

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

The VTX2 vortex meter is used for flow and volumetric measurements of conductive and non-conductive fluids, gases and vapours in all industrial branches. Applications include volumetric measurements for balancing (compressed air systems, heat carriers, vapours, chemical products, for example), process control and high throughput applications. Technical specifications • DN 15 - 300 (higher on request) • PN 10 - 40 • Flow rate 0,4 - 20000 m³/h • Measurement accuracy Gas and Steam: ± 0,9 % • Measurement accuracy liquids: ± 0,6 % • operating temperature according to design -40°C to +260°C, optional to 450°C Accessories • Strainer • gas separator • processing peripherals Advantages • high reliability • overloadable • interchangeable pressure sensor (optional) • measurements in harsh environments (vibration) is possible • good results even at low pressures and low volume flows

Request for a quote

EUROPEM

Belgium

Normal incinerators for waste gas and/or waste liquids are used to destroy the hazardous waste streams with an efficiency higher than 99.99% whilst maintaining low NOx, CO and TOC emissions. Each incinerator is designed to meet project specific requirements, using standard modules and concepts. Vertical incinerators are mostly used where high dust formation e.g. ash or salt, are present. Most liquid and waste gas incinerators are horizontally configured. Key Features - Horizontal or vertical arrangement – Executed with or without mixing wall – Custom burner arrangements with separate waste gas or waste liquid injection lances, in the incinerator front wall, roof or body. – Designed to maintain a minimum residence time, typically one or two seconds, at a minimum temperature, typically 850°C or 1150°C depending on local legal requirements. Key Advantages - Destruction efficiency over 99.99% – Production of clean flue gases at high temperatures, as input for waste heat recovery units – No CO formation and low NOx emissions – Complete odour destruction

Request for a quote

ERC ADDITIV GMBH

Germany

ERC AdBlue is used for the exhaust gas cleaning of passenger and commercial vehicles and added to the exhaust gas flow from a separate tank. The Effect With the combustion of diesel fuel, harmful nitrogen oxide (NOx) is created. It must be removed from the exhaust gas in order to protect the environment and comply with legal exhaust gas limits. The Result ERC AdBlue is a clear, non-toxic, synthetic urea solution stored in an additional tank near the diesel tank or in the boot of the passenger vehicle. It is not added to the diesel fuel. ERC AdBlue is used for the environmentally compatible exhaust gas post-treatment of diesel-powered vehicles by means of selective catalytic reduction (SCR system) and converts harmful NOx components of the exhaust gas into the harmless air components nitrogen and water. The benefits at a glance ERC AdBlue: Environmentally-friendly Removes harmful NOx from the exhaust gas Non-toxic and odourless ERC AdBlue is simply filled from the container...

Request for a quote

HILGENBERG GMBH

Germany

This compact micro torch is ideally suited for melting the ends of sample tubes precisely and safely. As a very small flame can be adjusted, it is possible to melt the capillary precisely at a defined point without excessively heating the remaining capillary, as is the case with standard torches. The torch is operated with a hydrogen/oxygen or a propane/oxygen mixture, both of which provide a very hot flame that even permits quartz glass to be processed. This torch is an extremely versatile tool with which practically all types of glass can be processed – from simple flaming to highly complex tasks. Features of the micro torch Fine, concentrated needle-point flame High heating capacity Mixed-gas operation Two separate needle valves Complete with fine nozzles Torch length >130 mm (without nozzle) Operating principle The torch consists of a gas mixing chamber and two gas inlets, which are also suitable for aggressive media such as hydrogen and oxygen. Two needle valves at the...

Request for a quote

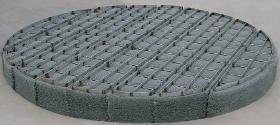

EMA INDUSTRY ENGINEERING SERVICES CO.

Turkey

EMA offers a variety of Demister Pad includes Wire Mesh Demister Pads and Filter Demister Pads for different process equipments handling liquid and vapor. Due to carry over of liquid particulate matter by gas or vapour, termed as entrainment is common in gas-liquid separations. It causes material loss and adversely affects the operational efficiency of the system. Constructed in a simple and light weight structure, it works by coalescing liquid droplets of smaller sizes. It results in increased collisions among the liquid drops forcing them to stick together in order to form bigger droplets that are too heavy to rise with the gas stream.

Request for a quote

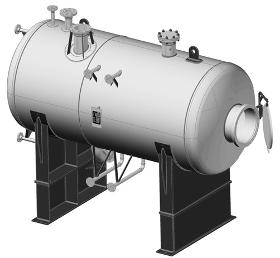

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Pressure vessel design Volume according to customer requirements OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement ACCESSORIES on demand level indicators condensate drainage systems sump heating GENERAL & FUNCTION The condensate tank type VKAB collects liquids and condensates, which are generated during the cleaning of gas in liquid separators. The condensates are discharged from the separators into the tank and serve for pressureless intermediate storage. The design is carried out as a steel welded construction in a horizontal design and is designed as a pressure vessel with 3 bar. QUALITY MANAGEMENT DIN EN ISO 9001 certified

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

ZPZ – VPZ 240°C-Filterelemente (Finalfilter) for cellular gas filters: ZPZ 25 – ZPZ 50 – ZPZ 80 – ZPZ 100 – ZPZ 150, type FFX Efficiency: 99,9 > 1µm In the area of fine dust separation, the gas is cleaned with filter cartridges. Our filter cartridges are all tested according to ISO 12103-01 and proven to be efficient, according to the requirements of the internationally valid “Test Aerosol: SAE-Fine Test Dust”. For special fields of application we can offer and develop special filter elements in order to achieve a performance-fulfilling filtration.

Request for a quoteResults for

Gas separators - Import exportNumber of results

34 ProductsCountries

Company type

Category

- Threads and yarns, artificial and synthetic (3)

- Air compressors - Tools and accessories (1)

- Boilermaking, heavy (1)

- Ceramics, refractory (1)

- Chemicals - Basic Products & Derivatives (1)

- Cooling and lubrication pumps (1)

- Filtration, chemical (1)

- Gas - production and distribution (1)

- Gases, compressed and liquefied (1)

- Import-export - steels and metals (1)

- Tanks, metal (1)

- Vacuum pumps (1)