- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas metal arc welding

Results for

Gas metal arc welding - Import export

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

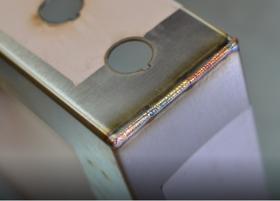

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"Argon-arc welding Electric arc welding Gas metal arc welding Arc welding"

Request for a quote

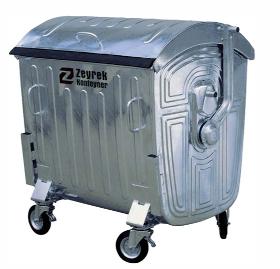

ZEYREK CONTAINER

Turkey

- Volume: 1100 L-Dimensions: 890 x 1350 x 1440 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. - Lifting arms are suitable for garbage truck lifting systems. - Cover movement is coil spring. - There is 1 stop mechanism on the lid.There is lastic profile on the lid mouth. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake. - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - All 1100 containers are fully produced under the EN840 compliant, to ensure the waste bin is compatible with customers requirements, such as trunnion and comb bar lifting devices

Request for a quote

ZEYREK CONTAINER

Turkey

-Volume: 660 L -Dimensions: 680 x 1150 x 1135 mm -Weight: 68 KG ( +/-5%) -Body sheet thickness is 1,50 mm. -The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. -Lifting arms are suitable for garbage truck lifting systems. -Container lifting arms are made of 32 inch. -Material: Galvanized Steel -Wheels: 4 rubber 150*45 in size. -Temperature resistant: 30"C to +8O°C -4 of the wheels rotate 360 degrees and 2 of them has a brake -Wheel connection sheet is 4 mm. -Our containers are welded with slag-free gas metal arc welding. -All of our products used in our containers are of first quality and TSE certified

Request for a quote

ZEYREK CONTAINER

Turkey

- Volume: 1100 L - Dimensions: 950 x 1200 x 1390 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - Lid is plastic lid. ( Green or other color ) - Lifting arms are suitable for garbage truck lifting systems. - Container lifting arms are made of 32 inch. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake. - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - All of our products used in our containers are of first quality and TSE certified 660 L and 770 L options are available. Production can be made according to the desired sheet thickness.

Request for a quote

ZEYREK CONTAINER

Turkey

- Volume: 1100 L - Dimensions: 930 x 1200 x 1390 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. - Lifting arms are suitable far garbage truck lifting systems. - Container lifting arms are made of 32 inch. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - AII of our products used in our containers are of first quality and TSE certified 660 L and 770 L options are available. Production can be made according to the desired sheet thickness.

Request for a quote

ZEYREK CONTAINER

Turkey

- Volume: 1100 L-Dimensions: 890 x 1350 x 1440 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. - Lifting arms are suitable for garbage truck lifting systems. - Cover movement is coil spring. - There is 1 stop mechanism on the lid.There is lastic profile on the lid mouth. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake. - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - All 1100 containers are fully produced under the EN840 compliant, to ensure the waste bin is compatible with customers requirements, such as trunnion and comb bar lifting devices. Production can be made according to the desired sheet thickness

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our weld wire sheathing material is used in both flux cored wire and metal cored welding wire processes. The wire sheathing is formed into a tubular product by our customers and the center of the tube contains the ‘fill’ (flux, metal powders, etc) to bring the wire to the desired chemistry. The finished wire is used across a wide breadth of industries in processes such as: Submerged Arc Welding (SMAW) Gas Metal Arc Welding (GMAW) Wire Arc Thermal Spray Flux cored welding wire producers use our metal sheathing materials to prepare finished wire for thermal spray and in surfacing applications, in high temperature and corrosive environments. Cobalt Our Ductile Cobalt Alloys are used to produce wire to hardface applications in the construction, mining, and oil and gas industry. Our proprietary process allows us to offer high Cobalt containing products (91% Cobalt or more) while maintaining a highly ductile strip for wire forming.

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Welding and cutting processes Depending on material and sheet thickness following processes are used: GMAW - Gas Metal Arc Welding (MIG/MAG) GTAW - Tungsten Inert Gas Welding (TIG), Cold & Hot Wire PAW - Plasma arc welding or cutting FSW - Friction Stir Welding Laser-Hybrid Welding RSW – Resistance Spot Welding igm robots may be used for all non-contact welding and cutting processes. Power sources from many well-known manufacturers can be integrated with our robot systems for welding and cutting applications. Products range from digital inverter power sources for MIG/MAG welding, TIG applications, plasma cutting and welding apparatus to high-capacity devices for the tandem process. Brushing, Grinding and Handling - Manipulation using Robots Through the possibilities afforded by a modular configuration of robot cells and the integration of diverse tools in the robot control sequence, significantly better throughput times and constant process qualities can be achieved. As a...

Request for a quote

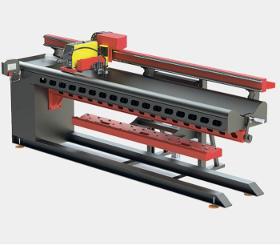

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Length Welding Machine is designed for length welding of cylindrical, conical and rectangular bent parts and flat plate sheet metal and plates. Parts between 100-3000 mm diameter can be welded on different machine types. The length welding machine, which offers the ability to make welds internally and externally, is produced from 1 meter to 4 meters long. In some special cases, the length may increase even more. Currently, workpieces with a minimum wall thickness of 0.60 mm can be welded. In submerged arc applications, the wall thickness is up to 20-25 mm. Boilers, water heaters, solar energy boilers, cooling tanks, natural gas chimneys, LPG tubes etc. Length welds of materials are made on this machine. Submerged arc, gas metal, tig etc. Welding systems work synchronously with our machine.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our company specializes in a wide range of welding services, with an emphasis on high quality welding welds. We use modern technologies that guarantee excellent results. We carry out welding of a variety of materials, including carbon/structural steel, stainless steel and aluminum. Our production facility meets stringent quality standards, such as PN-EN ISO 3834-2:2007 and PN-EN 1090-2:2018-09. We have implemented modern welding technology for group 1.1 and 1.2 carbon steels in accordance with PN-EN ISO 15614-1:2017-08. Our skills include working with steels such as S355J2 and steels with lower yield strengths, especially for material thicknesses above 3 mm for fillet welds (3-23 for butt welds), welded using the MAG-135 method. We provide professional execution of any steel welding service.

Request for a quote

VOSSE SP. Z O.O.

Poland

Our company meets the quality requirements of PN-EN 1090-1 standard for welding metal materials and has a quality management certificate in ISO 3834-2 welding Our welders are authorized to weld using methods such as: MAG 135 - welding metal electrode in active gas shield MAG 136 - arc welding in the active gas shield powder wire MAG 138 - welding with consumable electrode in the shield of active gas powder wire with metal core SAW 121 - submerged arc welding

Request for a quote

MR CO. LTD.

Ukraine

Argon welding is a popular name among people for welding technology, in which welding is performed in a shielding gas environment, most often argon. The gas prevents the metal under welding from coming into contact with the oxygen in the air, preventing oxidation. Inert argon is well suited for this purpose as it is non-toxic and relatively inexpensive. The equipment for argon welding comes in two types, TIG and MIG. In both cases, the machines are equipped with a non-consumable tungsten electrode. The difference is that TIG uses separate hard facing rods, but in MIG, the wire is fed automatically from the spool, for which people often call this method semi-automatic.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Access to the workpiece from the outer surface Installation close to the wall edge Linear welding with walking motion Circular welding on the rotating system Motion transfer with linear slides and trolleys Ability to connect welding machine, oxygen and plasma cutting unit Ability to create special applications and stations

Request for a quote

ONDERWELD WELDING EQUIPMENT

Turkey

We have all kinds of MIG torches swan necks

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Gas metal arc welding - Import exportNumber of results

17 ProductsCompany type