- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas compressors

Results for

Gas compressors - Import export

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

Poppe + Potthoff Maschinenbau GmbH supplies compressor units and pressure control systems of up to 400 bar for various gases. We offer ready-to-connect units to increase the existing pressure for pneumatic and hydraulic applications. In this way, the performance of existing systems can be increased flexibly and efficiently. Our compressor units are used wherever the existing system pressure is insufficient to implement specific applications. Of course, our systems are UL or CE compliant as required. In addition, we offer you service and support directly on-site.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

APROVIS

Germany

* FriCon - gas dehumidification * Gas heaters * ActiCo - activated carbon filters * Gas compressors * Process gas heat exchangers

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quote

AGGREKO CANNOCK

United Kingdom

Our 400 kW chiller offers efficient cooling for a wide range of process cooling and HVAC applications. For both planned projects and emergencies, our chiller hire services will meet your needs. Environmentally friendly R134a refrigerant gas. Portable 4.5 metre container frame with ISO lift facilities and forklift pockets. Unit base and frame made from heavy-gauge steel. 3 phase and earth electrical connections, no neutral cable required. Low sound attenuation for areas that are sound-sensitive. Hermetically sealed compressors to minimise potential gas leakage. Energy efficient compressor units ensure low running costs. Simple touchscreen control panel for easy use. Condenser and fan guards provide protection against accidental site damage. Microprocessor controller for accurate and reliable operation. Ideal for use across a variety of installations, such as air conditioning and process cooling applications. Environmentally-friendly. Fast installation and commissioning.

Request for a quote

EUROPE ZHAOHAN VACUUM PUMP CO., LTD

Hungary

Closed circulation vacuum system is consisted with liquid ring vacuum pump and compressor, liquid and gas separator tank, heat exchanger, instrument and valves, internal pipeline, and common base plate. The pumped gas enters the liquid ring vacuum pump/compressor from the pump inlet, after compressed by the liquid ring vacuum pump/compressor, the gas will enter to enter the gas-liquid separator together some of the working liquid. Inside the gas-liquid separator, the gas and liquid are separated, and the gas is discharged from the pump outlet, and the working fluid go from the heat exchanger and enter the liquid ring vacuum pump/compressor for recycling.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

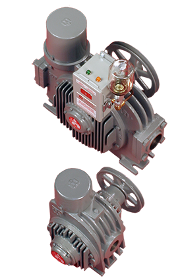

Proven in over 30 years of field operation, Waukee brand compressors are designed to be easy to maintain and service. This means that downtime is kept to a minimum. Features include simple design with few moving parts, rotary vane constructions, and built-in automatic closed-circuit unloader in which gas not needed is recirculated within the compressor. (Depending on pressure and flow rates, a bypass regulator may be used instead.) The 6-vane rotor is supported at both ends by factory sealed and lubricated ball bearings. Operation is relatively quiet. There are no gears, springs, or metal contacts. The low-friction vanes slide in and out of the rotor slots centrifugally. Capacity: The Waukee Rotary Vane Compressors can be provided from 200 cfh (5.6 cm/h) to 8,000 cfh (226 cm/h) at pressures up to 3 psig (20.68 kPa) on standard models.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Motors as driver used for a reciprocating compressor for gas compression in a refinery process.

Request for a quote

BFT GMBH

Austria

These test stations are designed for pressure testing of valves with an operating pressure of up to 5,500 bar. Gas compressors and pressure reservoir for testing with nitrogen as well as hydraulic stations for connecting and switching valve drives are available. The complete high-pressure valve test station is controlled with a central control panel. Mobile or fixed pressure testing pump can be used to generate pressures of up to 5,500 bar.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quote

FDT SRL DEPURATORI D'ACQUA

Italy

The compressor of the gas turbine is the component with the greatest impact on the performance of the turbine itself. It is therefore necessary that it is always perfectly efficient. The blading of the compressor, in addition, is subject to the surface deposits of impurities that accumulate during operation of the machine, it consists of the contaminants from the external environment (sea air, dust, fertilizers, etc.) And in part by the machine itself (vapors of oil from the compressor bearing). This creates the need to remove the deposits through the washing of the compressor, so as to restore the normal efficiency.

Request for a quote

KONTAKT LLC

Ukraine

Gas pressure regulators of the RDU type are designed to reduce and automatically maintain gas pressure “after itself” using the set value. Gas pressure regulators of the RDU type are used at the facilities for main gas pipelines: Gas distribution stations, Gas purification and dehydration installations, Compressor stations, Gas fields. Distinctive features of the RDU regulators: The simplicity of the device, Tightness at complete closure of the valve, Possibility to automate the reduction process. Upper setting limit, MPa/(bar)-1.2/(12) or 4.0/(40) depending on the setting device. Lower setting limit, MPa/(bar)-0.15/(1.5) or 1.2/(12) depending on the setting device. More information on our website.

Request for a quote

H2 CORE SYSTEMS GMBH

Germany

The HydroCab PowerCore is the complete energy storage system combining benefits of hydrogen and battery systems. It is a short and longterm energy storage system. The modularity enables the design of the best system for your demands. The system is designed for an easy plug and play installation. The PowerCore can be delivered in a water cooled or air cooled version. Also ask us for outdoor or IP55 versions with an exhaust connection. Optional compressors and gas storage solutions complete the system. We also offer the installation and commissioning on site.

Request for a quote

KONTAKT LLC

Ukraine

Gas pressure regulators RD-M are designed to reduce and automatically maintain the gas pressure “after itself” at the set value. Gas pressure regulators of the RD-M type are used at the facilities for main gas pipelines: Gas distribution stations, Gas purification and dehydration installations, Compressor stations, Gas fields. Distinctive features of the RD-M regulator: Hydrate formation in the “seat-valve” contact zone does not affect the regulator operation. Tightness at full closing of the valve. Smooth regulation characteristics due to the use of an oil compensator. High accuracy of maintaining the set pressure. High maintainability (possibility to repair wearing parts without removing the regulator body from the reduction line). Possibility to automate the reduction process. Upper setting limit, MPa/(bar)-1.2/(12) or 4.0/(40) depending on the setting device. Lower setting limit, MPa/(bar)-0.15/(1.5) or 1.2/(12) depending on the setting device. More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

Gas pressure regulators of the RDU-T type with a heat generator are designed for automatic regulation of gas pressure “after itself” of the set value at the facilities of high pressure gas pipelines. They are used at: Gas distribution stations. Gas purification and dehydration installations. Gas fields. Compressor stations, etc. The regulators are designed for operation at ambient temperatures from +50 C to -40 C and relative humidity up to 95% at a temperature of +35 C. Distinctive features of RDU-T regulators: The RDU-T regulators differ from the RDU regulators of the same class by the heating of the shut-off and regulating device in the zone of gas throttling using specially mounted heat generators which operate without an external energy source by taking a part of the kinetic and potential energy of the compressed main gas. The heating temperature is sufficient to prevent hydrate formation processes. More information on our website.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TOTALENERGIES LUBRIFIANTS

France

Ashless gas engine oil for use in 2-stroke and 4-stroke gas engines and compressors

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

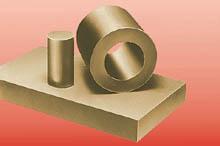

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

HAUG SAUER KOMPRESSOREN AG

Switzerland

Oil-free piston compressor, Gas-tight design with magnetic coupling (TOG) or shaft seal (TOD), TOG-compressor block leak rate < 0.0001 mbar l/s, Air-cooled or water-cooled options, Motor powers from 7.5 to 30 kW, Rotary speed range 970 to 1450 RPM, Intake pressure max. 16 bar, Final discharge pressure max. 100 bar, Modular cylinder configuration with cylinder diameter from 30 bis 180 mm, Versions with 2, 3 or 4 cylinders with 1-, 2-, 3- or 4-stages execution, Maximum flow rate at atmospheric intake pressure ca. 400 m3/h, Booster-variant flow rate max. ca. 1000 m3/h, Booster version, Version for explosion-protected plant (conforming with ATEX zone 1 or zone 2), Very robust and long-lasting construction, Compact and foundation-free installation.

Request for a quote

HAUG SAUER KOMPRESSOREN AG

Switzerland

Oil-free piston compressor, Gas-tight design with magnetic coupling, Compressor block leak rate < 0.0001 mbar 1/s, Air-cooled, Motor powers from 2.0 to 7.5 kW, Rotary speed range 970 to 1450 RPM, Intake pressure max. 16 bar, Final discharge pressure max. 300 bar, Modular cylinder configuration with cylinder diameter from 13 to 100 mm, Version with 2 or 3 cylinders with 1-, 2- or 3-stages execution, Maximum flow rate at atmospheric intake pressure ca. 50 m3/h, Booster-variant flow rate max. ca. 100 m3/h, Booster version, Version for explosion-protected plant (conforming with ATEX zone 1 or zone 2), Very robust and long-lasting construction, Compact and foundation-free installation.

Request for a quote

HAUG SAUER KOMPRESSOREN AG

Switzerland

Oil-free piston compressor, Gas-tight design with magnetic coupling, TIG-compressor block leak rate < 0.0001 mbar l/s, water-cooled, Motor powers from 37 to 110 kW, Rotary speed range 450 to 900 RPM, Intake pressure max. 16 bar, Final discharge pressure max. 100 bar, Modular cylinder configuration with cylinder diameter from 30 bis 260 mm, Version with 4 cylinders simple and double acting, 1-, 2-, 3- or 4-stages compression, Maximum flow rate at atmospheric intake pressure ca. 1'200 m3/h, Booster-variant flow rate max. ca. 1000 m3/h and by the high pressure variant max. ca. 200 m3/h, Booster version, Version for explosion-protected plant (conforming with ATEX zone 1 or zone 2), Very robust and long-lasting construction, Compact and foundation-free installation.

Request for a quote

HAUG SAUER KOMPRESSOREN AG

Switzerland

Oil-free piston compressor, Gas-tight design with integrated motor, Compressor block leak rate < 0.0001 mbar l/s, Air-cooled, Motor powers from 0.5 to 2.2 kW, Rotary speed range 970 to 1740 RPM, Suction pressure max. 20 bar, Final discharge pressure max. 60 bar, Modular cylinder configuration with cylinder diameter from 26 to 75 mm, Version with 1 cylinder for 1-stage compression, Maximum flow rate at atmospheric suction pressure ca. 10 m3/h, Booster-variant flow rate max. ca. 50 m3/h, OEM-integrated version available without pipework and instrumentation for integration in an OEM system, Very robust and long-lasting construction, Compact and foundation-free installation, Oil-free booster compression of nitrogen and air (CDA = Clean Dry Air), Oil-free recovery and compression of SF6 gas, Oil-free booster compression and recovery of helium, Oil-free compression of other gases as refrigerants, argon and carbon dioxid.

Request for a quote

HAUG SAUER KOMPRESSOREN AG

Switzerland

Oil-free piston compressor, Gas-tight design with integrated motor, Compressor block leak rate < 0.0001 mbar 1/s Air-cooled, Motor powers from 3.0 to 4.0 kW, Rotary speed range 970 to 1450 RPM, Intake pressure max. 20 bar, Final discharge pressure max. 300 bar, Modular cylinder configuration with cylinder diameter from 13 to 100 mm, Version with 2 cylinders and 1- or 2-stages execution, Maximum flow rate at atmospheric intake pressure ca. 30 m3/h, Booster-variant flow rate max. ca. 70 m3/h, OEM compact variant with integrated cooler over the electric motor and minimal pipework and instrumentation for integration into an OEM system. Version for explosion-protected plant (conforming with ATEX zone 2 externally), Very robust and long-lasting construction, Compact and foundation-free installation, Very quiet and hence suitable for installation directly at the workplace.

Request for a quoteResults for

Gas compressors - Import exportNumber of results

32 ProductsCountries

Company type

Category

- Compressors (6)

- Industrial valves, operating equipment (3)

- Gas, compressed (1)

- Gas - production and distribution (1)

- Lubricants, industrial (1)

- Biogas and biofuel - energy use (1)

- Compressed air tools and systems (1)

- Dosing pumps (1)

- Gas turbines (1)

- Hydroelectric power stations - installations and equipment (1)

- Polishing - machine tools (1)

- Polishing equipment and materials (1)

- Refrigerants (1)

- Steam turbines (1)

- Turbo-compressors (1)

- Vacuum pumps (1)

- Valves for industrial fittings (1)

- Water purification services (1)