- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forming lubricants

Results for

Forming lubricants - Import export

TRIBO-CHEMIE GMBH

Germany

Aqueous forging lubricant for hot- und warm die forging and extrusion Properties and Advantages • universal product for a wide range of application, especially deep cavity forging • film withstands several strokes from the hammer (up to 3) • replacement for saw dust thus improved die life, no smoke and increasing process reliability • automation possible = improved work environment • above average release property (effective expulsion) during the metal forming process • improved tool life (reduced wear) due to immediate formation of a heat-resistant and a protective film • excellent metal flow • perfect accuracy of the components produced, no build-up of inorganic residues • economical in use

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX® Wood Lubricant is used for lubrication and corrosion protection of woodworking machines, forming an ultra-fine lubricating film with strong fluidity. PROPERTIES Chlorine free Liquid Silicone free Neutral for all further treatments of wood such as gluing, staining and varnishing Does not form residues on treated surfaces AREAS OF APPLICATION For neutralizing resin For cleaning of stops, spindles, handwheels, holding jaws To prevent corrosion on bare machine parts To displace moisture

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Roadranger SAE 50 is a mineral oil-based lubricant designed for a wide range of applications, including Roadranger gearboxes, as well as automotive and industrial uses that do not require extreme pressure resistance. Thanks to its high viscosity index and low pour point, this lubricant forms a robust and highly adhesive film to safeguard gear teeth and bearings against wear. When the manufacturer recommends API service GL-1 or GL-2 gear oil, Roadranger SAE 50 is a suitable choice. It is also ideal for lubricating various manual transmissions in mild gear oil applications, as well as for use in some spiral bevel axle assemblies and worm gear drives found in commercial, agricultural, and truck equipment

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Jerko flow measurement is a unique success story since the beginning of the project. At the request of the German Massivumformung e.V., a sensor system for the reliable detection of spray quantities was developed. Of course, the partners of Massivumformung e.V. could rely on the innovative power of Jerko and now have the possibility to monitor their process even better. The sensor is suitable for all common forming lubricants - whether they contain oil or solids. Even non-Newtonian fluids are reliably detected. The sensor has a space-saving design and can be integrated into almost any spray system, even retrospectively. With the sensor you know even before the next forming operation whether the tool has been supplied with the required amount of lubricant and eliminate the resulting tool damage or consequential costs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Hybrid-Braid in W-Profile of heat conductive ePTFE Yarn with Silicon oil run in lubricant lubricant and form stable PTFE fibers Practical useful application data: max. temperature: +200 °C max. velocity centrifugal pumps: 16 m/s Characteristics Wear resistant through Running Track Reinforcement Very high heat conductivity through employment of a special heat conductive Compound Clean packing, no contamination of medium Increases the operative lifetime due to high mechanical strength and excellent heat conductivity Provides maximum protection of shaft against wear Recommended shaft surface hardness: HRC 25 Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 1 - 14 Density: 1.80 g/cm³ Practical useful application data: max. temperature: +200 °C max. velocity centrifugal pumps: 16 m/s Main application Centrifugal...

Request for a quote

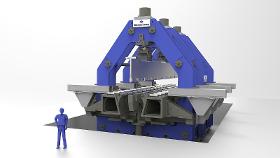

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Equipment operating under high temperature and load conditions. Bearings and gears operating in a warm, moist environment. Wet- and dry-end sections of papermaking machines. Advised when loaded gears form part of the lubrication circuit.

Request for a quote

BRAD-CHEM LTD

United Kingdom

Colloidal & non-colloidal Graphite or Molybdenum Disulphide stable dispersions in oil, water, or solvent. Can be used to add a solid lubricant extreme pressure additive to industrial engine oils, gear oils, chain lubricants, etc. Main uses include mould release, dye lubrication, forming & drawing lubricants, dry film lubricants, aerospace intrinsic lubricants, and refractory materials.

Request for a quoteResults for

Forming lubricants - Import exportNumber of results

10 ProductsCompany type