- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- foam processing

Results for

Foam processing - Import export

EXOTIC WHIP

Malta

Whipped cream is a “must have” for every foodie. But whipped cream is timeconsuming, and readymade cream doesn’t have much in common with good whipped cream. But if you buy a cream siphon, you can achieve a better result. This guide has info and tips that can help you make your buying decision. One device, multiple meanings. All designations are correct. This is a pressure stable, robust bottle. On the cap, depending on the model, there is a lever or button that triggers the foaming process. It is also equipped with a dosing nozzle. Depending on the product, several nozzles may be included in the scope of delivery. Siphons are available in three sizes 250 ml, 500 ml, and 1 l. Many can prepare more than whipped cream. Depending on the creation, creams, mousses, sauces, espuma, or foam crowns can be conjured up for various dishes. On the Internet, you can find many cream siphon recipes that you can try. Cream siphon function Fill the bottle with the liquid you have created.

Request for a quote

SFA ENVIRO

France

The FRMD is used to remove the upper layer of foam, oil or fats. The natural flow within the basin, together with the suction of the pump, attracts the surface of the water towards the center of the FRMD. An adaptable floating weir allows the upper layer to enter the pump and be removed from the basin. The weir and the submersible pump are mounted on a robust floating structure held in place by cables and springs or guiding tubes. Depending on the application and the geometry of the basin, the FRMD can be mounted together with a MIX SL (directional submersible mixer) or MIX-AS (floating downdraft mixer) to help the flow towards the weir. Applicable for removal of oil, fats, bulking + aging sludge, recycling of scum in sludge stabilisation + biogas, SBR and ASP tanks.

Request for a quote

SCHMITZ FOAM SUPPLY

Netherlands

XPE FOAM RECYCLING At Schmitz Foam, we don't just produce high-quality XPE foam, we also collect and upcycle foam residues into new foam products. When we deliver your RoFoam, we can collect your residual foam in one go. This saves you time and effort in disposing your residual product. It also reduces the amount of material waste and transportation required. Thanks to our recycling process our partners worldwide avoid environmental damage. Let us give your foam residues a purpose too 1. Contact us to find out if your foam residues suit our recycling process. 2. Together we determine how, when and where to collect your foam waste efficiently. 3. Save on elimination costs and prevent your foam residues from ending up in landfills or incinerators. 4. We recycle your foam residues and give it a purpose. All of the reworked XPE foam is used in new, high-end foam products. Please contact us, because together we can make sure that no foam goes to waste.

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX has developed a range of optimally balanced antifreeze products based on the requirements of global car manufacturers. With INOX antifreeze you can be absolutely sure that your car is reliably protected from overheating or freezing. Our antifreeze products have a high boiling point and a low freezing point guaranteeing long and uninterrupted operation of the car cooling system. Adding special components prevents corrosion and foaming processes as well as it minimizes cavitation.

Request for a quote

ORBIS EUROPE

Germany

ORBIS Europe offers large collapsible bulk containers for rugged industrial and automotive applications. With an extended length, collapsible design, the XXLPak is designed to handle, heavy, long and hard-to-fit parts. It optimises space utilisation at the same time. Our extra-long bulk containers are available with wide access doors and manufactured from high-density polyethylene using a structural foam-molding process for increased durability. Multiple footprints, heights, door configurations and labelling options are available in order to adapt our large bulk containers to customer’s supply chain needs. The extended length containers are designed according to American footprints and multiples of the European standard footprints. - For bulky, hard-to-fit parts - Durable, all-plastic design - Safe handling - Foldable and stackable - Ideal size for logistics and automated systems - Multiple heights and access door configurations

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

Key Specifications/ Special Features:Application:R141B refrigerant gas can substitute cfc-11 as foaming agent for rigid or soft PU foam without changing process and equipment or substitute CFC-113 as metal cleaner and solder-remover as well Physical and chemical properties:Under normal temperature and pressure, the product is a colorless, odorless and nontoxic gas Its melting point is -1604C, its Boiling point is -40.8®C and its liquid density is 1.213g/cms at 204C Its mixture with air is nonflammable and free of explosion risk It shows good thermal and chemical stabilities under normal conditionsStorage and transportation:The product is packed in appropriate cylinders or tanks (or tank cars) It is to be kept hi cool and dry place, without being exposed to heat source, sunlight and raining It is to comply with the regulations of railway and road transportation issued by Chinese government concerning hazardous cargo Packing specifications:

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® WORK is a highly effective silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Maxant® WORK is stable under extreme condition with low concentrations. Maxant® WORK is suitable for fully-synthetic working fluids and emulsion type working fluids. Permanent foam cut off Rapid foam knock-down Long durability in acidic and alkaline conditions Outstanding durability at low add on levels Excellent foam control Keep the initial performance Shear Stability Maxant® WORK is mainly designed for preventing foam in process applications. Maxant® WORK can be added directly into the foam solution. 1-20ppm is suitable for application.

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® PRO is a highly effective silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Permanent foam cut off Stable effects during storage period Rapid foam knock-down Foam inhibition in extreme temperatures (up to 95 °C) Long term foam inhibition Compatibility with wetting agents Long durability in acidic and alkaline conditions Outstanding durability at low add on levels Maxant® PRO is mainly designed for preventing foam in process applications. For process applications, we recommend prediluting Maxant® PRO silicone antifoam with cold water in a ratio of 1:1 to 1:10.

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® CLEAR is a highly potent silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Maxant® CLEAR is stable under extreme conditions such high temperature and competitively low concentrations. The low surface tension of the Maxant® CLEAR droplets enables the silicone to persistently flow into adjacent foam films and continue to break them down, minimizing the reapplication of the antifoam, potentially saving processing time. Permanent foam cut off Rapid foam knock-down Foam inhibition in extreme temperatures Long term foam inhibition Compatibility with wetting agents Ease in forming dispersions in all foaming systems Ease in forming dispersions in hard water Long durability in acidic and alkaline conditions Outstanding durability at low add on levels Excellent foam control Stays clear in different wetting formulations Maxant® CLEAR is mainly designed for preventing foam in process applications.

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® PRO is a highly effective silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Permanent foam cut off Stable effects during storage period Rapid foam knock-down Foam inhibition in extreme temperatures (up to 95 °C) Long term foam inhibition Compatibility with wetting agents Long durability in acidic and alkaline conditions Outstanding durability at low add on levels www.latro.com.tr Product Description Maxant® PRO is a highly effective silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Applications Maxant® PRO is mainly designed for preventing foam in process applications. For process applications, we recommend prediluting Maxant® PRO silicone antifoam with cold water in a ratio of 1:1 to 1:10.

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® WORK is a highly effective silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Maxant® WORK is stable under extreme condition with low concentrations. Maxant® WORK is suitable for fully-synthetic working fluids and emulsion type working fluids Permanent foam cut off Rapid foam knock-down Long durability in acidic and alkaline conditions Outstanding durability at low add on levels Excellent foam control Keep the initial performance Shear Stability Maxant® WORK is mainly designed for preventing foam in process applications. Maxant® WORK can be added directly into the foam solution. 1-20ppm is suitable for application.

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® CLEAR is a highly potent silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Maxant® CLEAR is stable under extreme conditions such high temperature and competitively low concentrations. The low surface tension of the Maxant® CLEAR droplets enables the silicone to persistently flow into adjacent foam films and continue to break them down, minimizing the reapplication of the antifoam, potentially saving processing time. Maxant® CLEAR is mainly designed for preventing foam in process applications. High acid and alkaline resistances enables Maxant® CLEAR to be used in processes both of pH and the final product apperance is critical. Permanent foam cut off Rapid foam knock-down Foam inhibition in extreme temperatures Long term foam inhibition Compatibility with wetting agents Ease in forming dispersions in all foaming systems

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® VOP is a highly potent silicone antifoam emulsion. Maxant® VOP offers excellent foam control and high stability in various foaming systems. Maxant® VOP is stable under extreme conditions such high temperature and competitively low concentrations. Permanent foam cut off Rapid foam knock-down Foam inhibition in extreme temperatures (up to 95 °C) Long term foam inhibition Compatibility with wetting agents Ease in forming dispersions in all foaming systems systems Long durability in acidic and alkaline conditions Maxant® VOP is mainly designed for preventing foam in process applications. Maxant® VOP can be diluted with water.

Request for a quote

OCV ITALIA

Italy

U801/U809 continuous filament mats represent specific solutions to homogeneously reinforce expanded polyurethane foam. CUSTOMIZED FOR P U FOAM PROCESS U801/U809 specific design helps to even mat expansion during the PU foaming process. U809 is compatible with CO2 blowing agent used in insulating material manufacturing process. Excellent glass/polyurethane bonding brings improved mechanical performance and dimensional stability to the PU foam. U801 superior drapability fits the most complex mold shapes. CORROSION RESISTANCE Excellent corrosion resistance with Advantex® Glass compared to standard Eglass providing longer service life in applications facing corrosion. U801/U809 mats are compatible with polyurethane resin systems and designed for PU foam reinforcement process. U809 is suited for LNG (Liquified Natural Gas) carrier cryogenic insulating systems. U801 is recommended for PU foam reinforcement in replacement of wood structure, in housing and recreational vehicle applications.

Request for a quote

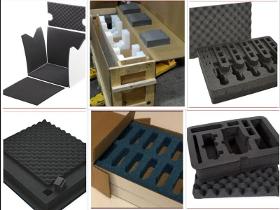

PLUS PACKING

Turkey

As a plus packing company, we apply the foam insert application for all fragile goods. Foam gives protection, durability and organizes your valuable goods. We use different types foams which are EVA, EPS, polyethylene and polyurethane foams to keep your goods secure along the transportation process. We customize foams based on shapes and apperance. Foam Packing Insert Features : . Organize the boxes .Shipment box organization . Protecs the tools .Interior Protection Keywords :foam insert, foam insert for tool boxes, foam insert for wooden boxes,custom foam insert, protective foam insert, protective case foam insert,Polyethylene Foam Insert foam insert packaging, foam insert for cases,foam inser for boxes,foam insert tray.

Request for a quote

PLUS PACKING

Turkey

We use a different types of foams materials to keep your products from the damage for the secure delivery process. Foams provide high protection to goods that keep away the them from damage and vibration along with handling and transportation. As plus packing, we customize foam based on product shape and dimension. We choose the most suitable foams to place your goods properly. Our main foam materials are ; polyethylene foam, EVA foam,polyurethane foam. Foam Packaging Features : .High protection from damage and Vibration .Safe delivery .Less cost .organize the tools . Customize your need for every type of foam

Request for a quote

PLUS PACKING

Turkey

As a plus packing company, we apply the foam insert application for all fragile goods. Foam gives protection, durability and organizes your valuable goods. We use different types foams which are EVA, EPS, polyethylene and polyurethane foams to keep your goods secure along the transportation process. We customize foams based on shapes and apperance. Foam Packing Insert Features : . Organize the boxes .Shipment box organization . Protecs the tools .Interior Protection

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SSA PANA FOAMTEC DOO

Serbia

We process polyurethane foams in blocks and in rolls. The main purposes of these raw materials are mainly the protection of sensitive goods during transport, air and water filtration, production of various self-adhesive and non-adhesive foam tapes. They are available in self-extinguishing and standard versions. We produce cut and stamped items from this raw material. Due to the open cell structure, Polyurethane foams are suitable for separating and attenuating sound and vibration. They are also suitable as permanently elastic buffers or as sealing tapes. In addition, they are resistant to many chemicals/solvents and high temperatures. For dust sealing, thermal insulation, sound insulation, shock absorption, vibration separation, upholstery and transport protection.

Request for a quote

SSA PANA FOAMTEC DOO

Serbia

Polyethylene foams have applications in countless industries. In the offer of our company, you can get flame-retardant, electro-conductive, anti-static and PE foams of various hardnesses. We process this type of raw material in rolls and blocks. PE foams are especially suitable for sealing and insulation. They are also resistant to many chemicals/solvents and have good resistance to UV and ozone. Polyethylene foam is used in automotive, construction, industrial, medical and orthopedic technology, electronics and many other sectors. We have: Physically cross-linked polyethylene foam with closed cell structure (corresponds to the guidelines of the automotive industry US FMVSS 302 and EU guidelines - RoHS 2002/95/EC) Chemically cross-linked polyethylene foam (financially favorable sound insulation and vibration damper) Non-cross-linked polyethylene foam with closed cell structure (ideal for protective packaging e.g. TV, computers, electronic or medical devices)

Request for a quote

JOST CHEMICALS GMBH

Germany

JC 640 is a release agent to pre-treat metal- and resin-molds in the field of polyurethane foam processing.

Request for a quote

DUALINVEST LTD.

Hungary

Isofoam Insulation is a monolithic insulation system. It is a three-component system of specially conditioned bulk alkaline earth silicate wool, binder and a foaming agent. The Isofoam installation process combines the bulk fibre with the binders in a patented mixing mechanism. Within the mixing chamber, the fibres and binders are combinated to create a homogeneous foam/fibre mixture. The Isofoam installation machinery propels the mixture through a feed hose and nozzle, the material is gunned onto the target surface and the interlocking network of fibres provides a strong, uniform monolithic structure. The proprietary Isofoam binder system and patented installation method completely encapsulate the fibres with the foaming binder, significantly reducing airborne fibre levels during isntallation.

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

We want to produce the optimal product for every application area. Our CNC portal Milling Machine for tubes offers to you a wide range of possibilities. When machining, you rely on us for perfect treatment. The CAM programming defines an optimal milling strategy, so we guarantee a customer-and product-specific machining solution as well as a high flexibility.

Request for a quote

KIMTEK FKM FILTRE LTD. ŞTI.

Turkey

Opencell or closedcell polyurethane foams are available in all common densities and in different colours. The elastic polyether foams show a relatively high resistance to acids and caustic solutions. In addition, they are much more resistant to hydrolysis and ageing than polyester foams. Accordig to a special process called reticulation is used to subsequently open the pores to almost 100%. By this a pore structure of even, opencell filter foams in controlled pore sizes of between PPI 10 up to PPI 80 can be achieved (PPI = Pores per Inch). A benefit of the polyester foams is their shockdamping property. In addition, polyester foams are less susceptible to light ageing than polyether foams.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPS MEANS OPTING FOR MAXIMUM FREEDOM. Technical molded parts made of expanded polystyrene (EPS) are the material of choice when it comes to good moldability, light weight, and outstanding insulation. EPS is ideal for the lost foam casting process. This involves embedding an EPS foam model of the desired component within a casting chamber in molding sand and dissolving it by pouring in molten metal. Compared to other processes, this affords greater design freedom when creating the cast parts, because neither built-in parts nor connections are necessary. As such, even complex cast components can be produced easily and particularly inexpensively. EPS also serves the construction industry well: Due to their very low thermal conductivity, technical molded parts are used as insulation elements and panels for underfloor heating systems. They can also be used as formwork elements. Whether for individual geometries or technically demanding structures, EPS makes it possible.

Request for a quote

PURIN POLYURETHANE

Turkey

Injection foams are liquid resins that can be injected into all gaps from capillary cracks to large cracks in concrete structures. It can be used in areas such as crack repair and building consolidation, especially in waterproofing, by converting from polyurethane liquid to solid by creating chemical reaction in seconds after injection process. Injection foams offer the possibility to apply in different forms for different purposes, from hard to very soft.

Request for a quote

REBEC SRL

Italy

Rebec supplies both flame lamination non-stop lines, with large production capacity and flame lamination lines with small and medium production capacity. Flame bonding machines can be simple, with manual adjustments or automatic adjustments of the working parameters by servo controls, PLC and PC. Our burners are made of cast iron made from solid bars. Cast iron burners have a longer life than aluminum burners especially if you process corrosive foams (some flame-retardant foams used for the automotive industry). In addition, the perforated ribbon to shape the flame slides on one side and therefore it can be easily and quickly removed for cleaning.

Request for a quoteResults for

Foam processing - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Shampoos (7)

- Foams, plastic (3)

- Bottles and jars, plastic (1)

- Boxes, plastic (1)

- Custom packaging (1)

- Diesel engines (1)

- Fabrics for technical use (1)

- Filtering equipment and supplies (1)

- Flexible packing (1)

- Foams, rubber (1)

- Foams, rubber and plastic (1)

- Hoses, pipes and tubes - plastic (1)

- Ice cream and sorbets (1)

- Insulation - injection materials (1)

- Polyethylene (1)

- Refrigerants (1)

- Textiles - Machines & Equipment (1)

- Thermal insulation materials (1)

- Treatment of industrial waste water (1)