- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flat-bottom tanks

Results for

Flat-bottom tanks - Import export

JOSEF JASPER GMBH & CO. KG

Germany

Flat bottom tanks according to DIN 4119, VdTÜV 960 and EN14015 up to diameter of 7.000 mm can be produced in our production site. Flat bottom tanks with larger diameter are prefabricated here and assemblied at costumers´ site by our qualified team. The manufacturing of backingspace leak detectioning double bottoms is also part of our range of services.

Request for a quote

ENDURAMAXX

United Kingdom

Cone Bottom Conical Tanks for Complete Drain Applications Cone Bottom Conical Tanks provide the ultimate solution for applications that require a complete drain. These help for the efficient processing of some liquids and can save money and time when compared to a flat bottom storage tank. Other applications for these conical cone bottom tanks include a settlement tank or sludge tank. A Unique Full Drain Solution Conical tanks are unique in that their contents discharge completely through a cone point at the centre of their base. Their cone base and smooth internal walls ensure complete discharge. This has clear advantages for food production, fermented beers, mixing tank, manufacturing and farming applications. Enduramaxx cone bottom tanks provide a unique solution with choices of a 5, 15, 30, 45 and 60-degree cone. This cone angle ensures maximum performance, with even the most viscous liquids not building up inside the tank.

Request for a quote

PARSMEGA MAKINA

Turkey

CSI silo wall sheets have a minimum tensile strength of 900,000 kgf/cm2 (63,200 Psi). These values clearly demonstrate our superiority over other silos in the market. ESI; offers strong, purposeful and durable commercial steel silos. Steel sheets made of very durable steel, wide corrugation spacings, heavy galvanized steel silo poles and matching roof gutters are some of the quality features available. Diameters of our commercial type steel silos; It has different dimensions from 4.57 m to 32 m. Extra different sizes are available in every diameter.

Request for a quote

SAMPACKT AMBALAJ SANAYI VE TICARET LIMITED SIRKETI

Turkey

Flat bottom bags can be made of Duplex and Triplex laminates. Welds on the edges of the bag and a flat bottom increase the stability of the package, make its presentation attractive, and the possibility of making a handle in the side fold increases the functionality of the package. For the production of Flat Bottom bags, Duplex and Triplex laminates are used , the inner layer of which is made of PE foil, and the outer layers can be made of PA, PET, PETmet materials. The manufacture of bags from laminates allows for the proper selection of the structure for the needs of the packaging, and the possibility of using a barrier layer allows to extend the shelf life of the packed product. Moreover, the use of interlayer printing in laminates protects the graphics against mechanical damage in the process of packing, transport and storage of ready products, and increases the aesthetics of the packaging and its functionality.

Request for a quote

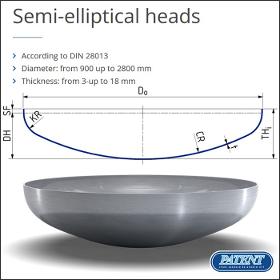

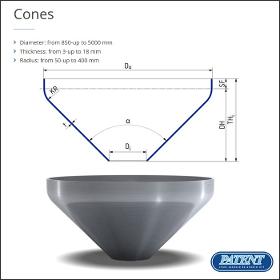

PATENT KFT.

Hungary

Elliptical heads (DIN28011) can be manufactured in stainless steel only. Flanging, bevelling, surface treatment, grinding and polishing, pickling, surface protection and nozzle cut-outs according to customers' requirements. Contact us, ask for a quote! Our staff will be happy to provide you with full information. Acronyms of the technical data: D = outer bottom diameter R = Dish radius s = Wall thickness H = Overall internal height without straight flange h = Height of straight flange

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PATENT KFT.

Hungary

Do = outer bottom diameter Di = inner bottom diameter CR = crown radius KR = knuckle radius SF = straight flange height DH = depth of head THi = full inner bottom height t = wall thickness.

Request for a quote

SILOS SPAIN INSTALACIONES, S.L.

Spain

Our silos, either flat or hopper bottom, are used for extended storage of large quantities of grain, seeds and granulate products. Our range of concrete base silos cover capacities ranging from 83 m3 to 45,055 m3 and with diameters from 4.58 m to 41.25 m.

Request for a quote

DSMART GMBH

Germany

Production Process of kraft flat bottom paper bags A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of kraft flat bottom paper bags A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quote

DSMART GMBH

Germany

Production Process of flat bottom coffee pouches A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of flat bottom coffee pouches A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quote

DSMART GMBH

Germany

Production Process of flat bottom pouches A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of flat bottom pouches A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quoteResults for

Flat-bottom tanks - Import exportNumber of results

11 ProductsCompany type