- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- finishing operations

Results for

Finishing operations - Import export

ISKUR BOYA

Turkey

Pre-Treatments / Finishing Cheese Painting Oppression Finishing Operations raising Carbon Brush Tumbled Gloss

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

NLTR Next Axis vertical with RFID, electronic lock metal, stainless steel finish, operation by Mifare Transponder, surface mount, with pull handle, shared use, incl. strike plate 2549

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

NLTR Next Axis Standard RFID, electronic lock metal, stainless steel finish, operation by Mifare Transponder, surface mount, with pull handle, shared use, incl. strike plate 2549

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Datapaq® offers the Oven Tracker® XL2 System, the latest generation of Oven Tracker systems for robust, comprehensive, intelligent and easy-to-use oven temperature profiling. For detailed information, download the Oven Tracker XL2 product brochure. Insight Oven Tracker Thermal Profiling Software Datapaq powerful Insight analysis software has been designed specifically to convert raw temperature data into meaningful information that can be used to understand, control and optimize your cure process. Complex calculations are simplified, allowing quick and comprehensive analysis. Detailed information of your oven gives you the reporting power you need in a detailed, certified and traceable profile report at the click of a button.Routine oven profiling has never been quicker, easier or more efficient. Send the Datapaq XL2 system through the oven and discover the true potential of your finishing operation. Simply 'plug & go' Easy data download from the MemoryPaq

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus tangential belts have been optimized to suit the diverse range of yarn-manufacturing processes and different drive shapes. They play a major role in ensuring consistently high yarn quality and efficient production due to the following characteristics: superior abrasion-resistant coatings made of elastomer G or polyurethane with constant friction coefficients and long service lives; optimized surface pattern for the spindle and motor side; less belt creep and excellent levels of power transmission; energy-efficient polyester or aramide tension members; polyamide sheet tension members with good damping characteristics for high levels of effective pull; low-noise and low-vibration operation; antistatic finishes. Siegling Extremultus tangential belts are supplied as roll material, prepared for splicing or have already been spliced. With our splicing methods, homogeneous, reliable splices can be made efficiently while belts are still on the machinery.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Net weight filling machines use a weigh scale platform to monitor the weight of product as it is filling into a bottle or container. Net weight fillers are well suited for large container filling applications. This type machine is used for 5kg -30 kg,and 50KG to 300KG, and IBC system liquid filling. both of gravity filling or pump feeding liquid system with weight scale under filling nozzle or under the conveyor to assure filling accuracy. It can finish a series of operations automatically, such as bottle inlet, weight filling, and bottle outlet. Especially for SL, edible oil lubrication. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.Linear type machine, can be made with 2/4/6/8 filling nozzle for different filling capacity.

Request for a quote

VERPET S.R.O.

Czech Rep.

Preparatory, finishing and other required operations are carried out using bench drills and grinders and other small tools. For example, we provide winding of electric motor components. Polishing and polishing of workpieces. soldering of printed circuit boards, soldering, welding

Request for a quote

TONAR-EKSPORT

Russia

The blades made of highcarbon alloy steel have an exact attack angle and provide easy drilling. Due to the 5762 HRC hardness, the blades can be resharpened many times without losing their original properties. Advantages of our blades • The blades are manufactured on the hightech Italian grinding equipment MVM “La 500”; • Due to the finishing grinding operation, the blades are perfectly sharp and keep sharpening for a long time; • The blades are treated with the special protective compound. The blades suit the following augers and drills • Tornado • Buran • Motoshtorm

Request for a quote

TONAR-EKSPORT

Russia

The ICEBERG 160R ice auger blades fit the ice auger ICEBERG with a diameter of 160 mm and clockwise rotation. The blades made of highcarbon alloy steel have an exact attack angle and provide easy drilling. The hardness of 5762 HRC allows the blades being resharpened many times without losing their original properties. Advantages of our blades • The blades are manufactured on the hightech Italian grinding equipment MVM “La 500”; • Due to the finishing grinding operation, the blades are perfectly sharp and keep sharpening for a long time; • The blades are treated with the special protective compound.

Request for a quote

TONAR-EKSPORT

Russia

The semicircular shape of Helios blades ensures easy and smooth drilling with minimal effort. Due to the 5762 HRC hardness, the blades can be resharpened many times without losing their original properties. Advantages of our blades • The blades are manufactured on the hightech Italian grinding equipment MVM “La 500”; • Due to the finishing grinding operation, the blades are perfectly sharp and keep sharpening for a long time; • The blades are treated with the special protective compound. To be used with • HS, Buran, Tornado ice augers; • Motoshtorm auger drill bits

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

The model VQ can be used as a classic Electric Multidirectional Sideloader for placing complete packs in storage, and with vacuum suction device for picking single sheets upto 120Kg. . With the HUBTEX VQ, individual sheets are vacuum lifted of the rack location and placed onto the fork tines of the fork-lift truck until the order picking operation is finished. Afterwards the order-picked goods can be loaded directly by the fork-lift truck onto a lorry for onward shipment. Handling of glass, individual sheets up to 40 mm thick or whole glass packs up to 8000 mm long and up to 3600 mm high and with a pack thickness of up to 400 mm can be transported. Operation and use: One-man operation for warehousing and order picking of non-porous panels made of different materials and glass sheets which can be lifted using the vacuum cups Load capacity range: 3,000 to 20,000 kg Lifting height: up to 7500 mm Aisle width: Load depth or cantilever arm length plus 1600 mm (if guided: with 100 mm safety clearance per side) Order picking ratings: ca. 70 sheets/hour ca. 420 sheets/day ca. 2,100 sheets/week ca. 8,400 sheets/month On average 27 sheets are taken into consideration for one order-picking operation. Approximately 2 hours per day are taken into consideration for refilling the racks.

Request for a quote

TONAR-EKSPORT

Russia

The INDIGO 120R ice auger blades fit the INDIGO 120R ice auger with clockwise rotation. The semicircular shape ensures easy and smooth dry ice drilling with minimal effort. A special and precise sharpening angle makes it easier to drill through the dry ice. Due to the 5762 HRC hardness, the blades can be resharpened many times without losing their original properties. Advantages of our blades • The blades are manufactured on the hightech Italian grinding equipment MVM “La 500”; • Due to the finishing grinding operation, the blades are perfectly sharp and keep sharpening for a long time; • The blades are treated with the special protective compound.

Request for a quote

TONAR-EKSPORT

Russia

The ICEBERG ice auger blades fit Tonar ICEBERG ice augers with clockwise rotation. The semicircular shape ensures easy and smooth dry ice drilling with minimal effort. A special and precise sharpening angle makes it easier to drill through the wet ice. Due to the 5762 HRC hardness, the blades can be resharpened many times without losing their original properties. Advantages of our blades • The blades are manufactured on the hightech Italian grinding equipment MVM “La 500”; • Due to the finishing grinding operation, the blades are perfectly sharp and keep sharpening for a long time; • The blades are treated with the special protective compound.

Request for a quote

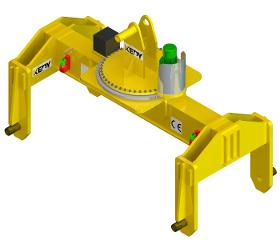

KEDY

Turkey

Introducing the KEDY K10100 Roll Mill Lifting Equipment, the perfect solution for your heavy-duty rolling mill operations. Designed with the latest technology and manufactured from high-strength materials, the K10100 is built to last and deliver outstanding performance. With its impressive load capacity, you can rest assured that your work roll will be safely and securely lifted and positioned every time. The K10100's size and shape are carefully crafted to fit your specific rolling mill design, ensuring a seamless integration into your operations. The surface finish of the K10100 is of the highest quality, providing durability and protection against corrosion and wear. Its connection points, such as hooks and lifting eyes, make it easy to attach and position your work roll, while its safety features, such as locking mechanisms and safety straps, ensure the safe and secure handling of your equipment.

Request for a quote

STARRAG GMBH

Germany

s230 is an automatic solution for faceting and diamond finishing dials index. s230 production center allows the production of a wide variety on index in various metals. Contrasts of different visual effects are performed by the use of diamond tools or solid carbide tools. The complete solution for small and medium series for finishing index combines multiple operations on a single machine. Features Optical recognition and origin definition of blanks Diamond with the revolver toolholder Machining of LuniNova pockets and micromilling Simple programming interface on Windows A variety of automation systems are available to ensure a high level of autonomy in production

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star HM range are bag sealers designed for lighter gauges of materials. The impulse sealers are capable of sealing up to 250 µm (1000g). There is also a constant heat machine for laminates and complex materials. Both hand and foot operated machines are finished in painted mild steel. A stainless steel food shop counter top bag sealer and tube sealer are also available. The robust construction allows for years of service with a full spares and service back up. Removable sealing bars allow for ease of maintenance and replacement of consumable items.

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Liquid soap dispenser in stainless steel (AISI 316L) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Onehand operated and nondrip soap pump with 200 ml tank. Designed for standard liquid soaps or hand lotions. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 70 x 170 x 90 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERNST WAGNER GMBH & CO. KG

Germany

Sensor liquid soap dispenser in stainless steel (AISI 316L) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. With touchfree operated and nondrip soap pump. Designed for standard 950 ml disposable bottles of liquid soap or hand lotion. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material, batteries and first fill with soap. Dimensions 86 x 298 x 121 mm

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Disinfectant dispenser in stainless steel (AISI 316L) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Onehand operation disinfectant pump with 950 ml tank. Designed for standard disinfectants for hands. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 80 x 298 x 120 mm

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Liquid soap dispenser in stainless steel (AISI 316L) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Onehand operated and nondrip soap pump. Designed for standard 950 ml disposable bottles of liquid soap or hand lotion. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material and first fill with soap. Dimensions 80 x 298 x 120 mm

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Liquid soap dispenser in stainless steel (AISI 316L) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Onehand operated and nondrip soap pump with 700 ml tank. Designed for standard liquid soaps or hand lotions. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 70 x 270 x 120 mm

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Liquid soap dispenser in stainless steel (AISI 316L) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Onehand operated and nondrip soap pump. Designed for standard 500 ml bottles of liquid soap or hand lotion. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material and first fill with soap. Dimensions 70 x 270 x 110 mm

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Liquid soap dispenser in stainless steel (AISI 316L) for surface mounting. Allstainless steel housing with rounded vertical corners. Visible surfaces satin finished and brushed. Onehand operated and nondrip soap pump with 700 ml tank. Designed for standard liquid soaps or hand lotions. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 80 x 248 x 120 mm

Request for a quote

ELMOR

Switzerland

Counting machine elmor C1: accessories and variants Conveyor bowls The parts to be counted with the elmor C1 counting machine are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Dual Product Outlet The dual product outlet can increase the productivity in Preset Mode (= repetitive batch counting). Each time when a batch is counted, the outlet switches to the other side and the counter restarts automatically. The dual discharge chute is intended to be used for counting crop seeds or corn, which are filled directly into bags, but can also be used for other seeds with 1mm diameter or more. Automatic Seed Weight Sorter Each single seed of a lot is automatically placed on a scale. The Automatic Seed Weight Sorter measures the weight of each seed and compares it with one or several limits. According to the result of this comparison, the weighed seed is then transferred into two or more containers. So the parts can weighed and sorted either into good and bad parts or into several weight classes. Filling Carousel The C1 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Filling adapter Adapter for small containers, bottles, laboratory tubes etc. This adapter allows dustfine and costly parts to be filled directly into containers. The C1 seed counter can be started only when a container is present.The filling adapters are manufactured individually on request. Dust Cover If specific small parts are processed, a dust cover can be of advantage. This is for example the case with pharmaceutical components, implants or with parts that need to be processed in a protective atmosphere. In this case, nitrogen or other gases or may be introduced through the dust cover. Ionizer When transporting small parts in the vibrating conveyor bowl there is a risk that the parts can become electrostatically charged. The correct separation of the charged parts becomes difficult. With an ionizer, the charged parts can be neutralised, shortly before leaving the bowl, in the region of the sorting element. The ionizer used in elmor C1 seed counter is manufactured by a specialized company, which is represented worldwide. The head of the ionizer is attached inside of a dust cover. Receipt Printer for Seed Counter elmor C1 The result of each completed count is printed automatically. The printing is done in plain text and bar code. During sample preparation or inventory counts many customers have expressed a wish to be able to print the determined number immediately. This can be done with this new accessories for the C1 counter. Faulty manual recordings are obsolete. Technical data: Paper: standard thermopaper rolls, 80mm width. Internal cutter, label length 64mm Barcode: Code 128 (International Standard ISO/IEC 15417), other codes on request Power supply: 100 – 240V, 50/60Hz The C1 seed counter must be equipped with an elmor printer interface board Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of the counting machines elmor C1, C3 or CX Intermediate storage container of counted parts When a seed counter is combined with a packaging machine, it may be advantageous to add a container for synchronization therebetween. When the counting operation has finished and the packing machine is ready, a discharge flap is opened briefly, so that the content of the container is discharged into the packaging machine. Then the flap closes and the counting machine begins with a new operation. As a result, the waiting time that would be needed before a packaging machine is ready for the next lot can be greatly reduced, allowing a shorter cycle time. Depending on the task different volumes can be realized.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

FMS, a METZEN Industries brand, has decades of experience building machinery and equipment. FMS manufactures machinery and equipment solutions from one-off products to medium-sized batches. Up to 20t without mechanical engineering Up to 20t including milling Up to 7.5t including turning Machinery construction On top of individual components and ready-to-install units, we also manufacture complete machines, including regulation and control technology. Our senior engineers develop them from planning and design to project management and installation, finishing with the complete operating documentation.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Rolling base for preliminary work operations and semi finishing to finishing operations

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Generally used for both rough machining and finishing. For finishing operations when the shapes are complex and with very accurate dimensions.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. RAFI Eltec operates 5 fully automatic SMD high-speed, precision assembly lines with nitrogen reflow soldering technology. Our focus: - BGA, µBGA, CSP - QFN, Finepitch - 0201 - Novel components - Package-on-package - Automatic optical inspection Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs.

Request for a quote

SYNTAX S.R.L.

Italy

The only Pick-up lathe with counter headstock for machining of part from opposite side to first gripping. The extreme precision and repeatability permits operations of turning, milling and, above all, finishing operations by grinding with wheel spindle and disk dresser, hard turning with CBN tools.

Request for a quoteResults for

Finishing operations - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Towel and soap dispensers (8)

- Hunting and fishing equipment and special products (5)

- Lubricants, industrial (2)

- Bag filling machinery and equipment (1)

- Blades, machine tool (1)

- Bottling and filling - machinery and equipment (1)

- Cutting - machine tools (1)

- Electrical & Electronic Components (1)

- Fallout shelters, construction (1)

- Grinding - steels and metals (1)

- Infrared tubes (1)

- Lifting equipment (1)

- Machine tools, metal machining - parts and accessories (1)

- Machinery and equipment, used and reconditioned (1)

- Transmission belts (1)