- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling solutions

Results for

Filling solutions - Import export

INATECH PACKAGING

Romania

Kraft paper for the FasFil1500 Packaging System is produced 100% from recycled paper, from responsible and SFI certified sources. It represents an efficient solution for filling the gaps in the box. Kraft paper is compatible with the FasFil®1500 Packaging System . The filling kraft paper has an ergonomic structure and can be recycled with other types of paper, thus contributing to the reduction of waste. The FasFil®1500 Packaging System is part of the category of gap filling systems with paper, representing a perfect solution for small packaging stations. The system offers easy paper loading and is specially designed to prevent paper jams. Specifications of the FasFil ®1500 Packaging System: the packaging system is designed to produce paper for filling the gaps manually, but also at programmed lengths; the system can be mounted on a stand, on the floor or on a table and adjusted to the desired height and angle;

Request for a quote

SYNERLINK

France

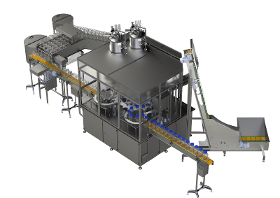

The ACCES filler series is dedicated to the edible oil market and has benefitted from Hema’s solid experience gained over several years of working for major International groups in the area of filling solutions for edible oil. ACCES is available in Monobloc configuration with capper or Combi associating blowing, filling and capping for PET bottles. We offer two filling technologies for edible oil : Weight – Mass Flow

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

the 888 is a rotary filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines 1400-2100 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste all size ranges

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

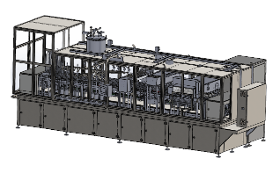

The 200A is linear filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines up to 24,000 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste and molasses in all size ranges.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

robot collecting cups filling solutions for high and fast production needs. Full Automatic Robot Collecting cups then arrangmrnt in special dish suitable for high capacity factories up to 25,000 cups/H

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

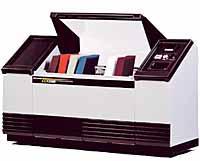

SF cabinets are used to quickly qualify a coating or material on a pass-fail basis, or determine the probability of corrosion of a specific material. SF applications include: Architectural, Chrome Plating, Fastners, Government, Military, Paints/Coatings, Laminated/Coated Plastics and Steel Structur Durable steel cabinet with 55 gallon (208 l) solution reservoir with mixing system on stand Cabinet heated by water jacket on four sides and bottom Exposure zone lined with corrosion-resistant PVC sheets Clear cover allows viewing of test conditions Peaked cover prevents dripping of condensation onto samples Water seal Heated humidifying tower with air relief valve Automatic DI water fill to humidifying tower Automatic solution level control Digital temperature control and readouts Certified air pressure gauge accurate to 1 psi (6.9 kPa) Integral over-protection on all heaters Low water cut-off protection on humidifying tower Two digital temperature controllers Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) SF260 - 420L, 0.76 x 0.56 x 0.99 m, 1.07 x 0.97 x 1.52 m SF500 - 555L, 0.76 x 0.74 x 0.99 m, 1.22 x 1.07 x 1.52 m SF850 - 860L, 1.14 x 0.76 x 0.99 m, 1.57 x 1.07 x 1.52 m SF2000 - 1930L, 1.83 x 1.07 x 0.99 m, 2.44 x 1.37 x 21.60 m SF3600 - 2850L, 2.36 x 1.22 x 0.99 m, 3 x 1.52 x 1.60 m SF4200 - 3680L, 3.05 x 1.22 x 0.99 m, 3.81 x 1.52 x 1.60 m Recorder, 2-pen circular chart, wet bulb and dry bulb UL approval Shut-down timer SF combination exhaust condenser and wet bottom drain SF exhaust recirculation system Precision air regulator, accurate to 0.01 psi (0.069 kPa) External collection package. Horizontal dispersion system High temperature package Chromasoft software High voltage kit (over 480 VAC) High capacity oil & water extractor Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

PEEKCHINA CO., LTD.

China

PEEK Ceramic Composites Elevate your applications with our PEEK ceramic composite. This advanced material combines the exceptional properties of PEEK with the added strength and durability of ceramic. Experience enhanced mechanical performance and wear resistance, making it the perfect choice for demanding industrial solutions. Choose PEEK filled with ceramic for precision and resilience in extreme conditions.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is a professional manufacturer of ceramic metering pump. The material we made for ceramic plunger pump is 99% alumina and zirconia, made by CIP forming and then with precision processing.Our business expanding in high-tech filling solutions for precision liquid filling in 2015, offer high grade accuracy, precision and durability. They are utilized in a broad range of Medical, Laboratory, Analytical and Industrial Process applications. All our ceramic filling pump products are Food Grade. There are three types of pump modules: Rotary, Linear and Multiplex which are used for different applications depending upon the customer's fluidic needs.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Top-tier solution for seamless filling. Crafted with a cantilevered heavy-gauge steel tubing framework, this filler ensures unbeatable strength and stability. Not just sturdy, it’s designed for easy accessibility with a three-sided access system, revolutionizing maintenance and filling efficiency. At Hapman, we understand that every application is unique. That’s why we offer a variety of options to customize our bulk bag fillers to meet your specific needs. You can choose from fixed or adjustable heights, as well as a range of custom features such as dust containment systems, load cells for accurate weighing, and more.

Request for a quote

RAYUEN PACKAGING CO.,LIMITED

China

simple but chic style cylinder round tube, features at bottom filling, made by full recyclable plastic PP and ABS material, can be used as ideal packaging solutions for filling lip balm and lipstick, available for wholesale and custom packaging design for private brands.

Request for a quote

RAYUEN PACKAGING CO.,LIMITED

China

Description: A plastic deodorant stick container at 15g filling capacity, a popular packaging solution for deodorants & suncreen balm that is available for wholesale and custom. It typically consists of a cylinderical tube made of plastic PP, with a twist-up mechanism at the bottom that raises and lowers the deodorant product. This plastic deodorant packaging container is designed to be durable, easy to use and portable, which can be customized to suit the branding and design requirements of different business. Moreover it can be made at PCR PP material for eco-friendly and sustainable purpose. Use for: empty containers for deodorants, foundation balm, suncreen stick etc. The decoration is available: customized injection color, color sprayed in a matte or glossy finish, silk-screen printing, foil hot stamping etc.

Request for a quote

IMBROS INC.

Bulgaria

A drum-type speed regulator made of medical polyethylene is used for more precise speed regulation, it has two scales: 0 to 250 ml/h for solutions with low viscosity (0.9% NaCL, 5% glucose and others); 0 to 200 ml/h for high viscosity solutions (20% glucose); 10. elastic adapter between the tube and the injection needle for additional introduction of the drug; Shelf life 3 years from the date of manufacture, as indicated on the packaging; Sterile, non-pyrogenic and non-toxic; Individual packaging. Instructions for use: 1. open the individual package, close the flow regulators, remove the protective cap from the needle, insert the needle into the cap of the infusion solution bottle; 2. Wait until the infusion solution fills 2/3 of the volume of the drip reservoir. 3; 3. open the flow regulators and release the air from the flexible pipe, the system is now ready for use; 4. Adjust the required infusion rate as needed; 5. The rotary knob has 2 adjustment sca

Request for a quote

CANALETAS

Spain

Superior quality, made entirely from stainless steel. Touchless water activation by large and robust stainless steel pedal/s or automatic activation by sensor/s. Elegant and robust fully integrated faucet in the dispensing area. Hygienic faucet design hidden water jet, separated from faucet walls, difficult to reach. Flat top plate enables bottles to stand properly. Vandal resistant model, the top plate can not be removed,allen screws. Easily regulated cold water temperature (thermostat). The installation of a purification filter is recommended for better water quality. A8OP Sensor for cold water. Ideal solution to fill bottles. A88 2OP Sensor for cold water. Sensor for room temperature water. Ideal solution to fill bottles. A8PE Pedal for cold water. Ideal solution to fill bottles. A88 2PE Pedal for cold water. Pedal for room temperature water. Both pedals simultaneously mixed water. Ideal solution to fill bottles.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The BATCHFLUX 3100 is an electromagnetic flowmeter (EMF) for rotary or linear filling machines. It is the economical solution for filling applications with conductive liquids.Due to its unique ceramic measuring tube, the mag meter features good repeatability and long-term stability. The flowmeter has an ultra-compact lightweight housing ideal for the tight spaces in volumetric filling machines. It can be used for filling of water or carbonised drinks. The EMF is suitable for common CIP cleaning procedures.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Solution for partially filled pipes The TIDALFLUX 2000 flow sensor with integrated and non-contact capacitive level measuring system provides accurate flow measurement in partially filled pipes. TIDALFLUX is designed to measure reliably between 10% and 100% of the pipe cross section. The integrated level sensors in the liner are in no contact with the liquid and are therefore insensitive against fat and oil floating on the surface.

Request for a quote

FILLTECH GMBH

Germany

Using highly advanced gas filling Small and Medium Enterprises technology is no longer a privilege for large enterprises. Over the last 15 years Filltech developed, in its own research center in the heart of Germany, different standard filling solutions. Through this experience, Filltech has now developed UniFill Complete; a standard gas filling solution for small and medium enterprises, using highly advanced technology. UniFill Complete is a ready-to-use, standardized CO 2 und N 2O gas filling station with a wide filling range for cylinders between 4 and 50 kg. Highlights Easy, precise and safe operation Entry-level, low-cost solution Automatic filling process with bypass valve Pumping set included Integrated pump control Legal for trade

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FILLTECH GMBH

Germany

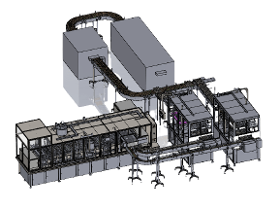

Costumer specific systems and Turnkey-Solutions Filltech designs, produces and implements fully automated gas filling solutions for the medical, consumer, industrial and special gas industry. All fully automated filling systems have been developed in close cooperation with the customer to ensure the best possible solution for their specific needs. Advantages Design of fully or semi-automated filling stations (in-house or in strong cooperation with your engineering team) One-stop-station for all necessary handling: emptying, cleaning, filling, weighing, leakage control, sealing and shielding In-house production of all filling stations Implementation at your premises Education at your premises 24/7 Back-up support available General capacity: 1000 CO 2 cylinders/hour IT-integration with your systems Track & Trace Ergonomic approach Conversions to AD2000 DIN/ISO 9001 ISO 22000 Module AI in accordance with RL 97/23/EG PED The following products might also be of interest to you: CO 2

Request for a quote

HILGENBERG GMBH

Germany

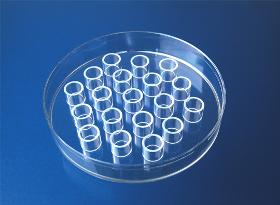

Cloning cylinders or rings are ideally suited for separate cloning if individual cells or cell groups on a nutrient solution. A specific cell or cell group is separated from the other cells in the nutrient solution by simply placing the cloning ring over it. The rings are made of high-grade borosilicate glass, and can be thermally sterilized without problems. The ring faces are ground perfectly flat, enabling the rings to be fixed e.g. to the floor of a Petri dish by means of a suitable grease. Subsequently, the nutrient solution is filled into the ring. The grease provides a seal between the ring and the Petri dish, whereby the precision-ground flat end ensures that very little grease is required to provide an optimum seal. The same applies in the case of Petri dishes prepared with a nutrient solution – here, the seal is provided simply by pressing the ring into the solution and down to the floor of the dish. Cloning cylinders

Request for a quote

EACTECH®

Portugal

The filling equipment for delicatessen that combines speed and efficiency The Filler EVC-2000 is the equipment you will want as an ally for filling in delicatessen. Chorizo, fresh sausage, sausage, salami, etc. It combines a 10-fin motor feeding system, reducing losses and preventing stains and bubble formation, while controlling the exact size of the portions. A filling solution for optimal results on your production line. The HF-250 hamburger maker is state-of-the-art equipment to produce a wide range of hamburger shapes and sizes. The mold filling system is automatic, guaranteeing uniformity and quality of the final product. Speed and pressure configured on touch panel Greater efficiency Extra income Touchscreen system Control panel with microprocessor Final product quality guaranteed 100%

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

DEDALUS LTD.

Croatia

Mouth Rinse Cups with rounded edges made from nontoxic polypropylene, for enhanced resistance and reliability with capacity of 180 ml, available in various colours. The mouth rinse cups in our assortment are available to you in a comprehensive range of colours and designs–whether you prefer classic white or something more colourful that better matches your office theme or other consumables. Mouth rinse cups are used in the dental practice for rinsing out patients' mouths during treatment. When it comes to teeth cleanings or periodontal treatments, the rinsing cups can be filled with a mouth rinse solution to support a successful treatment. During filling, prosthetic forming or following polishing, mouth rinse cups play the role of removing material residue from the mouth, which may have been left behind. Such cups are also convenient options for providing your patients with disposable drink cups in waiting areas or for use in post-toothbrushing mouth rinsing.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling and sealing systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling - Multi-component filling with different volumes is possible - Optimized filling process by spinning the container - Agitator systems for preventing product separation are optional - Synchronization interface for the bottling plant - Adding booklets, leaflets, spoon/spatula or give-aways possible as an option Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Insertion nozzle movement/ dosing amount adjustment: freely programmable, adjustable intake and dosing time, adjustable return suction - Different dosing technologies are available Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-flexofill

OPTIMA CONSUMER GMBH

Germany

Filling: - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product - Synchronization interface for the bottling plant - Vibrating the containers under the filling positions for product compaction and optimal utilization of the container's volume Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-fc2

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-40

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-5

FODAPACK

Turkey

This machine can make and fill single use sachet wet wipe full automatically. The machine can fill wet wipe liquid solution products and nonwoven wipe into the sachet packs together at the same time. Each pack has approx 2 – 8 ml solution and one non-woven wipe. Non-woven wipe is folded 2 or 3 times automatically and placed into the sachet pack by our machine automatically. The machine is suitable for the mid-range projects and professional manufacturers. Simple type and easy to operate for producing single use wet wipe sachets.

Request for a quoteResults for

Filling solutions - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (4)

- Automation - systems and equipment (3)

- Cosmetics (2)

- Bottling and filling - machinery and equipment (1)

- Ceramics, industrial (1)

- Cosmetics industry - machinery and equipment (1)

- Dentistry - products (1)

- Food Industry - Machines & Equipment (1)

- Food Processing (1)

- Goods handling systems, continuous (1)

- Measurement and regulation equipment and instruments - output and flow (1)

- Medical Equipment (1)

- Packaging materials - paper and cardboard (1)

- Plastic products for engineering (1)

- Transfusion equipment (1)

- Water distribution (1)

- Water retreatment - equipment and installations (1)