- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling equipment

Results for

Filling equipment - Import export

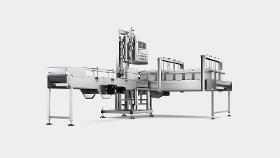

SYNERLINK

France

The COMBI adds value to any complete PET packaging line by combining blow molding, filling and capping into an integrated system. By eliminating conveying, empty bottle handling, accumulation and storage, the COMBI optimizes line layout with a linear compact footprint, improving production hygiene and efficiency while lowering operating costs. Our brand of filling equipment with blowing unit can be used for dairy products, as well as fruit juices, smoothies, nutritional drinks, coffees and teas, presented in PET. Express your creativity! Nearly anything is possible, from one-of-a-kind bottle shapes and decorations to unique over caps above screw caps, thanks to our various options

Request for a quote

BÜRKLE GMBH

Germany

The filling support makes it easy to dispense liquids and correctly dose from Bürkle's 10-litre compact jerrycan. The compact jerrycan sits on the inlets in the holder and is fixed in place with a tightener. That makes it impossible for the container to slip out. The jerrycan can be reliably guided with the swivelling holder and the liquid medium can be dispensed and transferred without expending any great effort. The jerrycan can be stored on the dispensing stand or it can be exchanged quickly and easily with a tightener. The filling support can be used wherever the compact jerrycan is used, for example in laboratories, in industry or in food applications.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-OF Automatic Multy Head Overflow Liquid Filling Machine works by feeding the liquid through a specific pump or a top storage tank. Simultaneously, once the feeding is completed, a portion of the material returns to the liquid overflow tank via the overflow port to guarantee the filled bottle in same level. The depth of the overflow port in the container neck determines the container’s filling level, which is easily adjustable. The number of filling heads can be increased to meet production needs. It’s ideal for filling low-viscosity, high foamy liquid in the chemical, food, pharmaceutical, and other sectors. Vacuum overflow filler system is for optional,filling nozzles moving up and down by servo motor driving, specially designed overflow filling nozzles.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The inline piston liquid filling machine is more flexiable, and suitable for a wide range of container size range from 100ml to 5000ml.It is has advantage of high filling speed, high accuracy and easy adjustment for different types of containers. It is application for any viscous liquid to thin liquid which is non corrosive the stanless steel, Piston filling machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and consistent dosing is important. They can handle a wide range of products with varying viscosities, from thin liquids to pastes and creams.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Net weight filling machines use a weigh scale platform to monitor the weight of product as it is filling into a bottle or container. Net weight fillers are well suited for large container filling applications. This type machine is used for 5kg -30 kg,and 50KG to 300KG, and IBC system liquid filling. both of gravity filling or pump feeding liquid system with weight scale under filling nozzle or under the conveyor to assure filling accuracy. It can finish a series of operations automatically, such as bottle inlet, weight filling, and bottle outlet. Especially for SL, edible oil lubrication. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.Linear type machine, can be made with 2/4/6/8 filling nozzle for different filling capacity.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Peristaltic pump liquid filling machine is one type of liquid filler which adapts the positive displacement pump as a dosing system.The pumps use the principle of peristalsis as the basis for their design. It is mostly application for filling small dosing liquid, for it is high GMP standard,and only the inner bore of the tube touches the fluid, it eliminate the risk of the pump contaminating the fluid, or the fluid contaminating the pump, so most of the phamarcy factories adapt this equipment for filling their liquid into small vial, such as eye drops, ear drops,phamarceuticals liquids, also some top cosmetics ,biology liquid also filling by the peristaltic pump. Feature Easy to install, simple to operate and inexpensive to maintain For different flavor liquids only change the tubes high filling accuracy for small dosing liquid, from 1ml to 100ml is the best filling range if consider both the filling accuracy and speed Servo motor driven, easy adjustable filling volume.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic detergent piston filling machine is a piece of equipment that is used to fill detergent products into bottles or containers. This machine operates by using a piston that pulls the product from a holding tank and then dispenses it into the containers. The process is automated, which means that the machine can fill a large number of containers quickly and efficiently. Feature: Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L Hopper: automatic liquid feeding system Container: suitable for 0.5-2L Plastic bottles Voltage: 220VAC 50/60Hz Power: 2000W Drop-proof filling nozzles: adapting vacuum sucking nozzles. Touch Screen Language: English and Chinese

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Manual Liquid Piston Filling Machine is suitable for filling small dose viscous liquid , it is adjustable for Cream,sauce,cosmetic Filling, operation by manual power. Filling range from 5ml to 120ml. Feature Reasonable Design: Designed with a high-quality filling head Easy to Operate: Add the filling material to the hopper, adjust the filling volume, then use the handle switch to control and finish the filling. Standard filling nozzles with OD4MM and OD8 mm, suitable for most of the products specification. Comfortable handle which helps improve user more easy operation The filling volume is adjustable by a mechnical screw, easier and faster

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTec dosing and filling pump RD-Hygiene for food and cosmetics is a volumetric pump based on the continuous piston principle. It is ideally suited for discontinuous or continuous pulsation-free dosing of viscous, structure-sensitive and solids-laden media. Thanks to the high-quality ViscoTec dispensers, high-precision dosing applications can be realized in the food and cosmetics sector. The systems are used e.g. in the bakery and confectionery sector for decoration. Typical doses are icing or fondant, but also fillings such as vanilla or chocolate cream. Your advantages: - Specially adapted filling tubes for a wide variety of filling applications - Application and dosing in automated systems - Low to high viscosity as well as abrasive, shear-sensitive or lumpy media - hot and cold filling - Optimum results for CIP/SIP (Cleaning in Place/Sterilisation in Place) cleaning

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Semi automatic Pneumatic volumetric Piston Filling machine is available with Single Head or double filling Heads.High quality and famous brand air cylinder ensure the machine work stably and fast.Make the machine suitable for fill viscosity and liquid.This semi-auto machine have 2 working mode for operation,auto and pedal. Feature Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-EVF economy automatic horizontal piston filler is equipment with 2 or 4 filling heads,the driven system can be air cylinder or a servo motor. Feature 1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machi machines are made of high-quality stainless steel, making them durable and easy to clean.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NPACK drum liquid weighing filling machine is a piece of packaging equipment used to weigh and fill liquids into 100L to 300L drums. A weighing platform (weighing system), a filling nozzle or several filling nozzles, a control panel, and a roller conveyor system comprise the majority of the equipment. The weighing platform measures the weight of the drum before and after filling to ensure that the correct amount of liquid is filled. The filling nozzle is used to transport liquid by gravity or pump from a storage tank or container to the drum. The operator can set and monitor the required weight of the filled drum, as well as regulate the filling process, using the control panel. The conveyor system is used to move the drums to and from the filling station. Main Applicaton fields: Oil Solvent such as thinner Liquid sugar Cooking oil and resin Resin Food and beverage such as soy sauce Paint and varnish Other liquid chemicals

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

A pail liquid weighing filling machine is a type of equipment used in the packaging industry to accurately fill liquid products, such as chemicals, lubricants, and food ingredients, into pails or containers. This machine uses a weighing mechanism to ensure that the desired amount of product is delivered to each container. Application It is application for Food and chemical industries,quantitative filling of coating, solvent, chemical raw material Features: The system uses PLC, touch screen, safe and reliable Filling nozzle and pipe use quick coupling, convenient for removing and washing Automatic 2-shift filling with high accuracy The nozzle automatically lifts when reaching the target filling amount Gross or net filling mode is available Be able to set and store 30 groups of formula for use Free to set target filling amount in order to be convenient for different packing Filling with one button, easy to operate (manual operation mode available)

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The IBC weighing filling machine is a sophisticated piece of equipment that is designed to accurately fill intermediate bulk containers (IBCs) with a variety of different products. These machines feature high-precision weighing systems that ensure accurate measurement every time, and they are capable of liquid filling IBC Application Filling 60L, 100L, 200L and 1200Ldrums and filling IBC and POLY TANK Directly filling the drums stocked on the pallet Resin, solvent, and varnish products Food and beverage products such as liquid sugar, cooking oil, and resin Liquid chemical

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The can weighing and filling machine for liquid, can be both automatic and semi automatic, the automatic one is a inline type and multi heads from 2 heads to 12 heads depends on the capacity demand;the semi automatic one normally is with nonzzles numbers from 1 to 2. Application It is application for Food and beverage, cosmetics and personal care, agricultural, animal care, pharmaceutical, and chemical industries.,Also used in jelly, pudding, fruit juice, ice cream cup filling, yogurt cup filling, honey, curd, buttermilk filling, and shrimpkhand filling with a single or double filling nozzles. It suits for filling multi liquids, low investment, easy cleaning.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container.

Request for a quote

BIZERBA SE & CO. KG

Germany

Filling system FSL-ECO S is the optimal entry level model for small companies who want to fill high-quality, uncritical and non-flammable liquids. With automatic filling as accurate as 1 gram this practical system lets you save time and money. FSL-ECO S offers particular advantages for companies where filling of liquid products is a firm part but not the main task in their production process. This system is the first step from manual to automatic filling. The semi-automatic system safely and reliably fills all common containers such as canisters, pails, drums or IBCs. Products are handled manually and the automatic filling provides to-the-gram results. You avoid over or underfilling and save valuable time.

Request for a quote

BIZERBA SE & CO. KG

Germany

The fully automatic filling system optimizes your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. By means of a multifunctional offset slide you benefit from maximum flexibility for container types and sizes as well as from efficient handling without retrofitting time. The fully automatic machine FSL-EVO S facilitates quick and reliable filling of high quality and sensitive products in different containers. Products can be fully automatically closed and labeled with variable data, if desired. By means of a set up buffer section the filling system largely works autonomously.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-WF Linear type Bottle Rinser by water is widely used for rinsing the new glass bottle and jars before filling. The rinsing can choose pure hot water or normal temperature purified water. The water after cleaning the bottles and recycling into the water tank for purify and heating again to reduce the water comsuption.The ultronic device is for option to meet the high requirement, Servo system bottle rinser Servo motor driven the bottle clamper to turn up 180 degree, the turning speed is frequency converter control. The rinse spary head are specially designed for different types of containers, ensure 100% rinsing the inside of the bottles. Rinsing head will insert into the container for cleaning. The machine is frequency speed control, change bottles no need additional changeover parts. A high pressure water pump and a water recyling pump ensure the rinse pressure and recyling water in time

Request for a quote

BÜRKLE GMBH

Germany

Universal thread adapter for nearly all drums and other containers with opening of 48–75 mm in diameter, regardless of the respective thread. The thread adapter can be mounted quickly and easily with clamping screws and can be used for different container openings. With G2" connector thread for Bürkle drum screw connections and pumps with immersion tube diameter up to 32 mm. The container connectors make decanting even easier and safer with their more secure connection to barrels. The connectors secure the pump in the barrel, enable a vertical position change and allow the required air exchange.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Training Operation and maintainging is including in our service, we will train the users how to operate,maintain the machines, and will teach them what is the points need to care, and how to clean the machine,what is needing attention,etc. We have some users, no technicians, no any Knowledge on running and operation machines. Npack will help you solve this issue. it is faster than employ and saving more cost. A liquid filling operation specialist will save time, cost and increaing the production efficient.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Good quality packaging of machine will Reduce the shipping risks.and the packaging will save your shipping cost, it will decide if booking a 20FC or 40FC or LCL. We have professional team do this job, they will make a drawing on a CAD to simulation loading a container. How are choose a packaging types? it depends on the equipments, but basically, strong packagings is a must.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Maintaining service and quality are both important,most of our customers have a long term cooperation is base on the maintaining service and quality of the machines.if the budget is not big difference, 99% of the visitor will choose our machines and our service.We cooperated with Unilever since 2012 and Kimberly Clark since 2020.Any liquid filling equipments need maintaining, no matter what is the quality level or brand, Npack offer maintainging service, instructions.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

every npack machines we will do the FAT,it is not only a FAT documents, also including testing video, training video,operation video.Normally, we will running the machines in our factory more than 24 hours. The FAT is not only checking the machine running stage,also checking if it is apply the industry standard, such as GMP, ISO, URL……

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Npack strictly manufactured the bottling machines according to our offer, all the technicians worked in this fields more than 6 years, and more than 10 years in automation fields.And an effectively production system help us save production and guarantee machine assembly quality. We adapt ISO9001 system,and company owned management system to control our production quality,every technician has its own responsibility.The quality control and technicals are both important.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

when we receive an inquiry from customer, important to know the details about requirements, bottle or container samples and the factory layout, then we will offer a professional quotation, normally takes less 5 days.Npack made the liquid bottling equipment according to the confirmed solution which including the layout of the liquid bottling line,machine parameters, technical sheets, fetures,main components list,especially the layout of the line is very important. Confirmation the solution is a strict and important step to order packaging equipments, it can protect double benefits.Npack service some big brand companies, such as the GSK, KIMBERLY CLARK, we have much experience on these, it is a working attitude, also a working mothed to gurantee the customer profits.

Request for a quoteResults for

Filling equipment - Import exportNumber of results

198 ProductsCountries

Company type

Category

- Bottling and filling - machinery and equipment (133)

- Bag filling machinery and equipment (42)

- Labelling machines (4)

- Amusements and attractions (3)

- Cooling and lubrication pumps (2)

- Dosing - machines and equipment (2)

- Engines & Parts (2)

- Food industry - machinery and equipment (2)

- Food industry packaging machinery (1)

- Bottles and jars, plastic (1)

- Cans, drums, casks and barrels, plastic (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Custom packaging (1)

- Dairies - machinery and equipment (1)

- Electricity generators (1)

- Food Industry - Machines & Equipment (1)

- Food Processing (1)

- Gas extraction - systems and equipment (1)

- Handling - Machines & Equipment (1)