- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- energy optimisation

Results for

Energy optimisation - Import export

ALPHA SOLWAY LIMITED

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

ALPHA SOLWAY LIMITED

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

ALPHA SOLWAY LIMITED

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

ALPHA SOLWAY LIMITED

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

GLOBUS GROUP

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

GLOBUS GROUP

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

GLOBUS GROUP

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

GLOBUS GROUP

United Kingdom

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Whether it’s for maintaining stable temperatures in storage tanks, compensating of heat loss in supply pipes, liquefying firm substances such as wax or vaporizing water or thermal oils, electrical heaters by Klöpper Therm are the answer. Our heaters provide optimised, energy efficient and reliable process control for all kinds of plants – chemical, petrochemical and pharmaceutical – as well as power plants and refineries. Based on the client’s specifications, we verify the technical feasibility for each application and transforms it into a concrete design.

Request for a quote

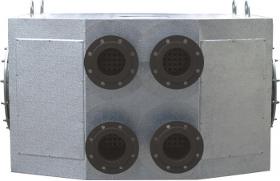

FRIGORTEC GMBH

Germany

The GRANIFRIGOR™ Tropic grain cooling units are performance- and energy consumption- optimised for the temperature and humidity of the tropical climate. Fields of application > Reliable grain cooling in tropical climates (heat, high humidity, monsoons and fog) - Secure control of air humidity due to HYGROMAT™ automatic > Complete suitability and reliable operation even at very high outside temperatures due to safety refrigerants > Standard medium pressure version - also ideal for tower silos > > Storage sizes from 2,100 up to 35,000 tons

Request for a quote

FRIGORTEC GMBH

Germany

The GRANIFRIGOR™ Europe range of grain cooling units are performance- and energy consumption-optimised for the temperature and humidity of European temperate conditions. Fields of application > Reliable grain cooling in temperate climates (rain, fog, heat and cold) - assured control of air humidity due to HYGROMAT™ automatic > Complete suitability and reliable operation even at high ambient temperatures due to safe refrigerants > Standard medium pressure version - ideal for tower silos too > Storage sizes from 1,300 up to 25,000 tons

Request for a quote

FRIGORTEC GMBH

Germany

The special grain cooling units for hot dry countries of the GRANIFRIGOR™ Desert series are performance- and energy consumption-optimised for hot desert climates. Fields of application > Reliable grain cooling in very hot countries - Safe control of air humidity due to HYGROMAT™ automatic > Complete suitability and reliable operation even at extremely high outside temperatures due to safety refrigerants > Standard medium-pressure version - also ideal for tower silos > Storage sizes from 12,000 t up to 25,000 t

Request for a quote

FRIGORTEC GMBH

Germany

The GRANIFRIGOR™ Subtropic grain cooling units are performance- and energy consumption-optimised for the temperature and humidity of the subtropical climate with tropical summers and non-tropical winters. Fields of application > Reliable grain cooling in warm temperate climates (rain, fog, sultry, heat and cold) - secure control of air humidity due to HYGROMAT™ automatic > Complete suitability and reliable operation even at very high outside temperatures due to safety refrigerants > Standard medium pressure version - ideal also for tower silos > Storage sizes from 8,200 up to 25,000 tons

Request for a quote

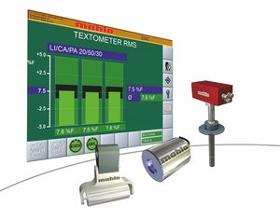

MAHLO GMBH & CO. KG

Germany

Measurement of steam Much unused energy is wasted through the exhaust air during drying processes without appropriate control. The Ecomat AML optimises the heating energy required by monitoring charging of the exhaust air with water steam and controls this factor through the fan speed or the exhaust air vent control.

Request for a quote

FORKLIFT ENERGIE

France

FORKLIFT ENERGIE works with you on the on-board power supply for your industrial equipment (AGVs - forklift trucks - special mobile lifting machines) and works with you to define the equipment best suited to your needs - batteries, controllers, converters, drives and innovative equipment. FORKLIFT can help you switch your electrical equipment from lead batteries to LFP lithium technology. Guaranteed safety: Lithium batteries no longer require charging rooms, no longer emit explosive or corrosive gases, and no longer represent a danger to your staff or your facilities. Optimised profitability: lower energy consumption, elimination of maintenance costs... Your technical and environmental constraints are our constraints. Autonomy and safety for your teams: The longer life of lithium batteries helps to improve working conditions and protect teams from musculoskeletal disorders (MSD).

Request for a quote

MAHLO GMBH & CO. KG

Germany

Optimizes drying The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for monitoring and controlling residual moisture, product temperature, dwell time and exhaust air humidity can be flexibly adapted to current production. Up to three of the same or different modules may be used as needed. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SDT ULTRASOUND SOLUTIONS

Belgium

LEAKChecker is an ultrasound solution designed to find compressed air and vacuum leaks in noisy environments. Focused Compressed air leaks are a senseless waste of energy. Find and fix them fast with SDT LEAKChecker; an ultrasound solution focused on reducing waste and saving you money. Simple LEAKChecker is so easy to use. Simply open the box, switch it on, and start finding leaks. Enjoy crystal-clear sound in the headset and a vibrant colour display. LEAKChecker makes leak surveying fun again. Affordable Air leaks are an expensive problem… and LEAKChecker is the affordable solution. Built with SDT quality, it’s offered at a price that will leave you speechless. LEAKChecker, in combination with LEAKReporter, SDT provides clients with a platform to detect, log, and generate reports that show how their initiatives contribute to a more sustainable environment.

Request for a quote

Q-INTERLINE A/S

Denmark

The InSight Pro concept offers a modern and future-ready in-line analyser solution. We have taken all unnecessary complexity out of the product to offer a high-end solution that is easy to purchase, install and run for years. InSight Pro offers measuring devices adapted for various sample types. One or two measuring points can connect to the analyser via flexible optical fibres. > What can you achieve: - Faster start-up - Stable process - Produce closer to target - Less waste and rework - Full traceability - Energy optimisation - Predictability > The InSight Pro systems offers the customer : - A maintenance-free system - One or two measuring points - Full CIP/SIP compliance - IP65 protection for easy installation - 3-years warranty - Choice between five configurations - Built-in 24/7 surveillance - Same analyser engine used at-line - Operator-friendly software – InSightView

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The powerhouse among our ContiRoll® impresses by its robust design and well-tuned components. This enables to build extremely long plants equipped with even more powerful motors and more resilient roller rod chains. There are no concessions to be made to excellent board Qualities! Features Patented exible press infeed to ensure an optimal evacuation of air and direct heat transfer Optimised energy consumption in the partial-load section by using the EcoDrive Innovative process control technology to ensure a self-governing operation High-quality hot platen material makes wear plates superuous thus ensuring a direct heat transfer Foundation beams, frame unit and hot paten of the press have dierent thermal dilatation. An advancing speed of up to 2000 mm/s Pressure proles adjustable in longitudinal and transversal directions

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

One ContiRoll® variant has been suited to the Chinese market: the 4-ft press concept. It is considered to be the optimal solution for the characteristically small factories in China. Nonetheless, it has all the important features of a big ContiRoll®. Especially the exible infeed head enables the production of thin MDF (≥ 2.0 mm). Other advantages: unrivalled uptime, very good pressure distribution, very low thickness tolerances and a fast start-up, relying on fast commissioning of all the components. This press type therefore produces high-quality boards in a resource-ecient production process. Features Material savings by optimal pressure distribution Optimised energy consumption Patented exible press infeed to ensure an optimal evacuation of air and direct heat transfer Innovative process control technology to ensure a high degree of automation An advancing speed of up to 1300 mm/s

Request for a quote

ENHA GMBH

Germany

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

ENHA GMBH

Germany

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

ENHA GMBH

Germany

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

ENHA GMBH

Germany

Crashbox Inside optimises energy distribution and dissipation upon an impact to keep the force transfer to the head extremely low.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

An experienced team of engineers work within the Design department at POITTEMILL and FORPLEX, building upon over 100 years of expert knowledge. Assisted by qualified design technicians and uptodate technological computerized tools ( fluid mechanics design programmes, latest 3D technologies, CAD HP Workstation Z420 workstations), the Design department is able to offer a complete range of services to help you precisely determine your needs and define a solution that takes into account the economic, environmental, spacial and security constraints of your project. The services provided are as follows Feasability studies, Writing of specifications, Audit of existing installation, Maintenance, energy and optimisation advice, Particle size analysis and testing, Studies, supply and commissioning of complete installations.

Request for a quote

TAMA AERNOVA SRL

Italy

Cutting Table with structure for maximum thicknesses of 30mm sheet metal 260 A. The LT downdraft cutting table, integrated with a laser, plasma, or oxyfuel cutting machines, enables the sustain and processing of the sheet metal plates, with the required extraction of fumes & dust, and a slug collector system Benefits The suction table is divided into sections, activated by the cutting machine, to concentrate fume and dust extraction only where suction is necessary, reducing the air flow required and optimising energy consumption.The suction table can support sheet metal plates with a maximum thickness of 30 mm, and torches with a maximum power of 260 A. The slag containers could be easily removed from the top (after the lifting of the counter frames) without interfering with the outer structure of the machine, to simplify the slag empting procedures. The cutting bars of the counter frames can be individually replaced, in an easy and fast way. The LT downdraft cutting table is...

Request for a quoteResults for

Energy optimisation - Import exportNumber of results

28 ProductsCompany type

Category

- Motorcycle helmets (12)

- Cereals and grains (4)

- Boilers, industrial (2)

- Measurement and control instruments (2)

- Wood veneer - machinery and equipment (2)

- Heating, domestic - installations and equipment (1)

- Technical design consultants (1)

- Textiles - Machines & Equipment (1)

- Ultrasonic measuring equipment (1)

- Warehouse logistics (1)