- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- emulsifier

Results for

Emulsifier - Import export

ORFIN SP Z O.O. SP. K.

Poland

Juicy and fragrant fruits with dark purple skin. Their trees can be found in every Polish orchard. Our delicacy is a sour fruit immersed in the delicious sweetness of chocolate. On the packaging there is an illustration of tenement houses in Gdańsk. Ingredients: plum 69% (prune, preservative: potassium sorbate), chocolate (cocoa mass, sugar, cocoa butter, emulsifier: soy lecithin, natural vanilla flavor.

Request for a quote

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

Used for the production of mineral oil based soluble metalworking fluids. Composed of emulsifiers, EP/AW additives, lubricants, corrosion inhibitors and specialty esters Product prepared with 18-22% of soluble oil emulsifier and balance spindle oil gives milky oil in water emulsions Emulsifiers are used in, • Textile machine oil, blend oil, cone oil products • Soluble oil ( boron oil) metalworking oils • Textile machine knitting oil products • Wax emulsions for textile fabric treatment • Concrete ad plywood form release oils • Cottong picker – harvester machine solvents • Preparation of pesticides emulsifiable in water • Emulsifiers are used to ensure that the bitumen particles are dispersed in water for asphalts

Request for a quote

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

Product prepared with 8 – 10 % emulsifier and mineral base oil gives milky oil in water emulsions for textile fiber processing. Used for textile oil preparation for spinning, synthetic and wool fiber blending, cone transferring, kamgarn and streighgarn spinning operations Nonyl Phenol free nonionic type emulsifier package gives highly hard water resistant stable emulsions up to 100 DH Emulsifies easily and gives high degree of lubrication and washability. Eliminates static electric deposition during spinning

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Ultra-high viscosity and vacuum emulsifying mixer adopts a combination of high emulsifying , low speed stirring and combining. In the process, the material is processed repeatedly with heavy shearing force, compressing, grinding, homo-mixing and dispersing. The stirring paddles scrape off the material attaching on the inner surface as they rotate to increase the effect of homogeneous mixing. Thus, under high speed of processing, high viscosity, fine particles and homogeneous fluid with soft and fine color can be obtained in a single machine.

Request for a quote

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

Forms complete film formation on needle surfaces and lubricates needles perfectly Composed of nonionic/anionic emulsifiers, anti wear and anticorrosion additives 8-13% emulsifier admixed with white oil gives clear transparent knitting oil product Emulsifier does not deteriorate its colours and forms complete film formation and perfect lubrication on needles Heat resistant emulsifier package does not interact with knitted fabric surface during heat fixation step and supplies perfect scouring & washing effect.

Request for a quote

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

lubrication of cotton and corn picker harvesting mobile equipment Composed of non ionic emulsifiers and used 8-10 % for the production of high performance cotton picker solvents by admixing with base oils. Emulsifier is highly resistant to hard waters on application sites and gives very stable long life emulsions up to 100 DH water hardness Emulsifier enables picker solvent emulsions to be completely spreading on the surfaces of needles and gives perfect lubrication and washing affect.

Request for a quote

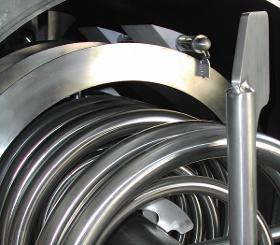

KASAG SWISS AG

Switzerland

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

BEKOSPLIT splitting plants clean emulsified condensates which occur as a result of unfavourable initial conditions or of certain lubricant/compressor combinations. In addition to compressed-air condensate, other oil-containing industrial wastewaters can also be processed. Water-insoluble organic substances and a large variety of solid contaminations are removed from the water. Any heavy metals, dirt and paint particles contained in the water are reliably adsorbed

Request for a quote

TIANJIN YR CHEMSPEC TECHNOLOGY CO.,LTD.

China

BTMS Conditioning Emulsifier is an excellent cationic self-emulsifier and conditioner for both hair and skin care. BTMS Conditioning Emulsifier offers innovative properties to formulations as both a mild primary emulsifier and an excellent conditioning agent.Creams and lotions made with BTMS Conditioning Emulsifier leave a soft, powdery feel on the skin. Because BTMS Conditioning Emulsifier is substantive to hair, it imparts excellent body and spring and improves wet combing. Due to its extreme mildness, it is suitable for leave-in conditioners. BTMS can be used as sole emulsification system in creams, lotions or hair conditioners. BTMS can also emulsify many silicones (up to 50% in a formulation).

Request for a quote

SAPON COSMETICS OE

Greece

Poppy seed achieve a light exfoliation and provide softness to the skin. Red clay helps to regenerate cells. Jasmine scented. Keep it in a cool, dry and shady place in its packaging. Ingredients*: Sodium Olivate, Glycerin, Sodium Cocoate, Sodium Palmate, Sodium Sweet Almondate, Sodium Castorate, Prunus Amygdalus Dulcis (Sweet almond) Oil, Aqua (water), Parfum, Illite (Red Clay), Papaver Somniferum Seed

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 60-ton containerised bitumen tank is a tailor-made, mobile storage setup that safely accommodates and moves a large volume of bitumen. These tanks are constructed within a robust, containerised structure, specifically to be easily mobile with fast turnarounds in deployment. Their compact design allows them to be space-efficient in terms of storage and handling, thereby making them an ideal solution for industries that require flexible and temporary bitumen storage. These tanks are particularly suitable for projects that require mobility, such as road construction or remote infrastructure developments. They give a practical, versatile option for a myriad of industrial applications by encapsulating all necessary components for bitumen storage and transport within a robust container.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 3000-ton horizontal bitumen tank is a mega storage unit designed to hold and manage huge volumes of bitumen, thick sticky liquid produced from crude oil. Constructed horizontally, these tanks are built in a way that not only maximizes storage space but also permits the heating and transfer of bitumen effectively and efficiently. These tanks are made from hard-wearing materials like high-grade steel to endure all odds in bitumen storage and thus to keep the material secure and stable through their storage and transportation. A horizontal bitumen tank of 3000 tons is mainly designed to ensure a strong and reliable solution for industries that consume large amounts of bitumen. This large capacity, specially designed, maintains the bitumen either to be used directly in road construction, asphalt production, or waterproofing projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A sizable specialized storage tank built to hold and handle substantial amounts of bitumen—a thick sticky material made from crude oil—is a 120-ton horizontal bitumen tank. Because of the horizontal design of these tanks bitumen can be stored heated and transferred more effectively. These tanks are designed to withstand the harsh conditions connected with bitumen storage and are made of sturdy materials like steel. A 120-ton horizontal bitumen tanks main function is to offer a dependable way for bitumen to be stored in industries that need big amounts of the material. In addition to making maintenance and operation simpler the tanks horizontal orientation guarantees that bitumen can be efficiently heated and maintained at the proper temperature for a variety of industrial processes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 100-ton horizontal bitumen tank is a medium-sized, specially designed storage unit meant to hold and manage bitumen, one of the by-products from the refining of crude oil. The tanks are designed to store significant volumes of bitumen and are therefore crucial in industries that require volumes of the same material, such as asphalt production and road construction, among other industrial processes. The horizontal design of the tank provides efficient storage and easy access, thereby allowing heating, handling, and transfer of bitumen. A 100-ton horizontal bitumen tank is fabricated from high-grade raw materials, including steel, for storing a medium that represents some of the toughest conditions of any storage process: the corrosiveness of the product and the high temperatures needed to keep it in a workable state. In this respect, the design will ensure that the tank remains intact for years to come, providing a safe and reliable solution for the storage of

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A horizontal bitumen tank is a specially designed storage unit to accommodate the safe and efficient storage of bitumen, a thick sticky substance produced from crude oil. Such containers are of key importance in industries such as road construction and waterproofing or roofing, among other industrial procedures where bitumen is a major material. They normally feature in asphalt plants and bitumen treating facilities as storage reservoirs for the bitumen to be used in several works. Design for horizontal bitumen tanks is specially tailored to manage the unique properties of bitumen. It is designed to be quite difficult to handle at low temperatures because of its high viscosity. These are fitted with systems to keep the bitumen at the right temperature, ensuring it stays within an easy workable state for transportation and easy use. It offers a controlled environment of storing bitumen to ensure that the material is always ready for construction and industrial usages.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Polygonmachs Bitumen Emulsion Plant is a specialized facility designed to create bitumen emulsions of the highest quality. This plant creates emulsions that meet the exacting requirements of modern road construction by utilizing state-of-the-art technology to combine bitumen water and additives. The plants design allows for the efficient production of stable homogenous emulsions which are essential for many applications such as surface treatments and waterproofing. The Polygonmach bitumen emulsion plant includes a number of crucial processes and operations. These consist of applying heat to the bitumen emulsifying it stabilizing it storing it and strictly monitoring its quality. The plant heats the bitumen to the necessary temperature to ensure that it maintains the proper viscosity for emulsification. The heated bitumen is subsequently mixed with water and emulsifying agents to produce a stable homogeneous emulsion suitable for use in road construction and reconstruction.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Introduction of Asphalt Vibrating Screen An asphalt vibrating screen is one of the most critical machines at asphalt-producing plants and in many construction locations. Its role is to filter and perform size classification of aggregates, thus ensuring conformance of materials used in asphalt mixtures to specified requirements. This screening process lies at the heart of producing quality asphalt that can perform and last in road construction projects. The vibrating screen efficiently sorts aggregates to ensure the right consistency and composition of the final asphalt mixture, which is an important requirement in a paved surface for strength and durability. Application of an asphalt vibrating screen does not just act in the role of material filtering, but rather, it directly affects the quality of the asphalt products realized. Without proper screening, uneven gradation may result in the product mixture, and this unevenness can result in weaknesses in the pave.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Mobile Aggregate Sand Gravel Dosing Bunker? The Aggregate Sand Gravel Dosing Bunker is a movable device used for storing, dosing, and transporting aggregates such as sand and gravel. This mobile facility is specifically very useful in those industries where flexibility and efficiency of material handling play a vital role, like construction, mining, and infrastructure projects. It is portable, thus easily transferrable from one site to another, making it the solution of choice in projects that need on-the-go material supply with dosing capability. This bunker system is designed to provide a convenient, on-site aggregate management facility with the minimum of fuss and maximum reliability. Be it for roadworks, concrete plants, or any process requiring the exact and repeatable dosing of materials, this machinery truly provides outstanding versatility to keep any operation running smoothly.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What Is a Bitumen Drum Barrel Heater Decanter? In road construction, the Polygonmach Bitumen Barrel Heater Decanter is one of the important machines in the field, and hence, it is so important in the construction industry. The main work is heating and liquefaction of bitumen. Bitumen usually comes in solid or semi-solid state in standard barrels. The process makes the bitumen ready to use in various activities involving construction, mostly in building and road maintenance. This machine ensures that bitumen is in the right state for application; hence, one is assured that the expected execution and projected long-term quality and durability of a road construction job are met. The use of these heaters/decanters is hence widespread owing to how effectively they change bitumen from the stored state into the state that it can be used as a liquid.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Asphalt Manufacturing Facility The stationary hot mix asphalt plants from Polygonmach are not transportable instead they are fixed in one place and intended for large-scale asphalt production. With capacities ranging from 60 to 400 tonnes per hour these plants can produce asphalt continuously which makes them perfect for large-scale projects. Their main job is to combine aggregates like crushed stone sand or gravel with a binder called asphalt cement to create high-quality hot mix asphalt which is an essential material for road construction and maintenance. Asphalt Plant Near me A vital part of any asphalt plant is aggregate storage. The plant stores aggregates in sizable bins or stockpiles which include sand gravel and crushed stone. These components which make up the majority of the asphalt mix are first sorted according to size and quality before being added to the mixing process.

Request for a quote

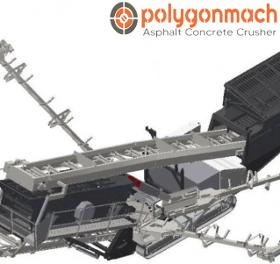

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Mobile Wheeled Crushing Screening Plant is a versatile and mobile plant used in various industries for crushing, screening, and sorting operations. This type of plant is mounted on wheels for easy transportation between various job sites and, therefore, allows for efficient on-site processing of materials. A mobile, wheeled processing plant performs the main function of transforming stones, minerals, or construction waste into given dimensions according to the need and separating and screening processed material with respect to given specifications. These are high-turnover, critical plants in the construction, mining, and recycling industries, in which flexibility and mobility are important for maximizing operational efficiency and reducing transportation costs. The common mobile wheeled crushing screening plant mainly includes a primary crusher for an initial crush, secondary crushers for processing further, and screens to separate the crushed material into various sizes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Technical Specifications of Our Track Mounted Impact Crusher Our track mounted impact crusher is engineered to deliver exceptional performance and efficiency. It boasts a robust capacity of 120 - 250 t/h, making it suitable for a wide range of crushing applications. The rotor size, measuring 1,050 x 820 mm, ensures efficient crushing, producing high-quality aggregates. This crusher's impressive weight of 41,800 kg reflects its solid construction and durability, capable of withstanding the most demanding conditions. These technical specifications are a testament to our commitment to providing high-performance equipment that meets the needs of our customers. Optimized for High Capacity Crushing Designed with a capacity range of 120 - 250 t/h, our track mounted impact crusher excels in delivering high throughput, making it an ideal choice for large-scale projects. This high capacity ensures that you can process significant volumes of material efficiently

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Unveiling the PTV800: A High-Performance Track-Mounted VSI Crusher The PTV800 model of our track-mounted VSI (Vertical Shaft Impact) crusher is engineered for excellence in the most demanding crushing applications. With a robust rotor type, optimized for closed settings, this crusher delivers unparalleled efficiency and precision. The closed rotor design enhances the crushing process by ensuring consistent particle size and shape. This feature makes the PTV800 ideal for applications requiring precise material output, such as sand production and tertiary crushing. Its robust construction and innovative design ensure that it performs reliably even in challenging environments. Exceptional Feed Size Handling and Efficient Design The PTV800 is designed to handle a maximum feed size of 38 mm, making it suitable for a wide range of materials. This capability ensures that the crusher can efficiently process different types of input materials, from soft stones to hard minerals.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

An 80-ton welded-type cement silo is a large storage container designed mainly to hold big amounts of cement in construction and industrial settings. The metal panels used to build this type of silo are joined by welding so that they are very strong and sturdy, thereby enabling them to hold big volumes of cement. These silos can hold 80 tons of cement, ensuring a large storage and continuous, effective supply of this required construction material at the working site or the cement manufacturing plant. Leakages and structural failures, caused by poor welding, are eliminated by the welded feature in the 80-ton cement silo; thus, the quality of the cement stored is maintained. It has access doors, level indicators, and discharge systems which make the process of loading-unloading of cement easy.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 75-ton welded type cement silo is a huge storage container used in the construction industry for the storage of cement. The silo is composed of panels of welded metal to give it strength and durability in storing large amounts of cement. Here we present the silo with a capacity of 75 tons, providing great storage capacity for cement. Without it, the supply of this critical building material would be very effectively managed on construction sites. The welded construction of the silo not only lends stability to it but also precludes any leakage, thus maintaining the quality of the stored cement inside. This makes the 75-ton welded type cement silo a strong and trustworthy storage facility that forms a key part of building works to ensure continuity in cement supplies for various building projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 30-ton Welded Type Cement Silo refers to the used specialized storage structure to hold a large quantity of cement in a welded construction. These silos are mainly applied in construction projects, concrete production plants, and industrial projects by which efficient storage and supply of cement are highly required. The welded-type silo design involves welding together the component parts into a robust, seamless storage unit that can bear the weight and pressure of bulk cement. These silos are designed to have a capacity of 30 tons, providing medium storage volume for medium-scale projects that require both a continuous and reliable supply of cement. The application demands regarding cement storing and dispensing are served by a 30-ton welded type cement silo. The welds guarantee the structural integrity of the silo, providing a safe environment for the stored cement.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 50-ton horizontal type cement silo is generally a storage structure implemented in construction projects for storing and distributing cement. Unlike the traditional vertical silos that stand tall, horizontal silos are laid out horizontally; hence, it becomes quite easy to transport and commission on a construction site. These silos can be easily mounted on a trailer for easy movement and then securely placed on the ground for usage. Conveying systems are put in place to pump the cement out if need be, providing continuous supply of cement during construction activities. The 50-ton capacity assures carriage of enough cement at one time, thus guaranteeing continual work without constantly refilling. Convenience, efficiency, and reliable storage for construction projects characterize this size of a horizontal type cement silo.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 25-ton Horizontal Type Cement Silo is a special storage container used for storing as much as 25 tons of loose cement positioned horizontally. Generally, it is used at construction sites, concrete batching plants, and other industrial plants where a constant supply of cement is required for continuous concrete production. The horizontal design allows for easy loading and offloading of cement. In fact, access to the stored material is easily made at ground level. Normally made of rigid material such as steel, these silos are sturdy and reliable, offering safety in storage while the cement is being protected from outside influences. The Horizontal Type Cement Silo, for example, is endowed with a capacity of 25 tonnes, amply suitable for medium and large construction works where this type of cement is in great demand.

Request for a quoteResults for

Emulsifier - Import exportNumber of results

88 ProductsCountries

Company type

Category

- Concrete preparing - machinery and equipment (67)

- Bitumens (6)

- Bread & Cakes (2)

- Cosmetics (1)

- Cleaning - steel and metals (1)

- Food flavourings (1)

- Food supplements (1)

- Foods, precooked and gourmet (1)

- Knitting machines and accessories - industrial (1)

- Lubricants, industrial (1)

- Lubrication equipment and machinery (1)

- Mixers and grinders for the food processing industry (1)

- Organic cosmetics (1)

- SWEETS (1)

- Textile finishing (1)

- Waste water recycling (1)