- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electronic industrial robotics

Results for

Electronic industrial robotics - Import export

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Cam Followers are bearings with a stud that incorporates needle rollers in a thick walled outer ring. These bearings are designed for outer ring rotation and provide superior rotational performance, a low coefficient of friction and high load capacity. In order to effectively increase the loading zone, this bearing is designed to have a smaller radial clearance than general needle roller bearings, so the shock load is lessened and stable long life can be obtained. Since the studs already have threads or steps, they are easy to mount. Cam followers are follower bearings for cam mechanisms and linear motion and have high rigidity and high accuracy. They are used mostly for machine tools, industrial robots, electronic devices, and OA equipment. Stainless steel cam followers have superior corrosion resistance and are suitable for use in cleanrooms and environments where oil cannot be used or where water might splash.

Request for a quote

PJM MECHANICAL CO.,LTD

China

Low Backlash: Backlash is under 3 arcmin.Backlash for 2 stage speed reduction is within 5 arcmin High Efficiency:Efficiency for 1 stage model exceeds 95%,2 stage model exceeds 92% Size:PLF060/PLF080/PLF090/PLF120/PLF160 Output Rated Torque Range:From 9Nm to 500Nm Adapter-bushing connection,can be attached to any motor No Grease Leakage and Maintenance-free Planetary Gearbox Application:Aerospace,military industry,Medical health,electronic information industry,Industrial robots,production automation,CNC machine tool manufacturing industry,Auto industry,textile,printing,food,metallurgical,environmental protection engineering,warehouse logistics industry

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Housings for electronics - customized moulded parts, milling of metal materials. Our milled metal components are widely distributed. Machined parts are used in: -the medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Aluminium custom made milling component for mechanical engineering. Flange for industrial automation. Our machined parts are used in: -the medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation. Technically advanced CNC processing services with 3- and 5-axis CNC milling work allow us to meet clients’ specific requirements and by our client’s request we provide surface treatments. Our focus is on quality manufactured and quick delivery times while keeping a competitive pricing level.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

We specialize in CNC processing of small to medium series (1 – app. 5000 pieces). Our main activity is production of individual custom components, from more to less demanding and complex precise milling components. Using Mastercam CAD/CAM software our experts deliver high-quality precise parts for control lines, assembly, robotics, custom prototype devices and more. Our custom milling parts are widely distributed. Machined parts are used in: -medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation. Specializing in various sectors of development companies, we offer advanced custom parts. We are working with wide range of materials like aluminium alloys, plastic, metal and steel but 70 % of our production is CNC aluminium processing and milling of plastic materials. Our focus is on quality manufactured and quick delivery times while keeping a competitive pricing level.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Aluminium CNC precise parts for aerospace. Using CNC 5-axis milling work produced components faster and with greater accuracy. In the machine park there are 3- and 5-axis simultaneous CNC machining centres that ensure to satisfy even the most demanding clients. Using Mastercam CAD/CAM software our experts deliver high-quality precise parts for control lines, assembly, robotics, custom prototype devices and more. Our milled metal components are widely distributed. Machined parts are used in: -the medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Steel custom milling parts became part of pallet systems for industrial automation. Our main activity is production of individual custom components, from less demanding to very demanding and complex ones. Machined parts are used in: -the medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation. Specializing in various sectors of development companies, we offer advanced custom parts, working with materials like aluminium alloys, plastic, metal and steel. Our technically advanced CNC processing services allow us to meet clients’ specific requirements and by our client's request we provide surface treatments.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Custom made plastic components for production lines in the medical field. In the machine park there are 3- and 5-axis simultaneous CNC machining centers that ensure to satisfy even the most demanding clients. Using Mastercam CAD/CAM software our experts deliver high-quality precise parts for control lines, assembly, robotics, custom prototype devices and more. Machined parts are used in: •the medical fields, •electronic equipment, •automotive industry, •aerospace, •intelligent robotics and •Industrial automation. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Aluminium CNC precise parts for aerospace. Using CNC 5-axis milling work produced components faster and with greater accuracy. In the machine park there are 3- and 5-axis simultaneous CNC machining centres that ensure to satisfy even the most demanding clients. Using Mastercam CAD/CAM software our experts deliver high-quality precise parts for control lines, assembly, robotics, custom prototype devices and more. Our milled metal components are widely distributed. Machined parts are used in: -the medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

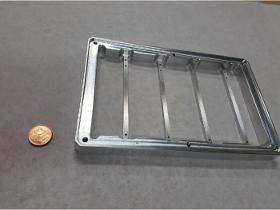

Metal parts as aluminium screen housings for aerospace. Using Mastercam CAD/CAM software our experts deliver high-quality precise parts for control lines, assembly, robotics, custom prototype devices and more. Machined parts are used in: •the medical fields, •electronic equipment, •automotive industry, •aerospace, •intelligent robotics and •Industrial automation. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible. All dispatched products are functional and visually sophisticated. Which leads to better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

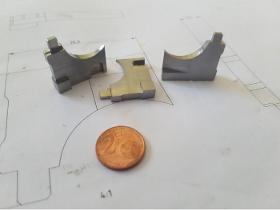

Small precision parts for electronic equipment. Our machined parts are used in: -the medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation. Specialized in smaller productions has its own advantages. We individually devote ourselves to our partners. The advantages of this kind of cooperation is review of technical documentation before production and possible adjustments made beforehand, which leads to more affordable and better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We also create the programs ourselves to “breathe life” into machines and robots. After commissioning, we can run extensive performance tests. Industrial robots are the optimal solution for complex movements or systems with highest flexibility. We integrate and program the appropriate robot such as the Kuka robot and other brands.

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KDTECH SP. Z O.O.

Poland

Final assembly We perform complex tasks that require specialist skills, precision and accuracy in action to deliver the highest quality product in its final stage

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

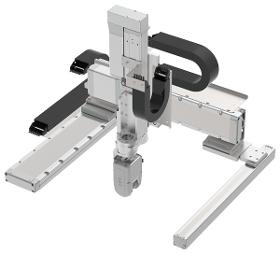

Cartesian robots can be adapted very well to the respective application conditions due to their modularity. They also take up less space than 6 axis robots, for example, because they only have the functionalities that are actually needed. IAI offers rectangular robot as 2-6 axis combinations with 230 V servo motor in hundreds of configurations as standard or precision types. An equally comprehensive portfolio of cost-effective Cartesian RoboCylinders is available. There are 396 possible combinations for them, including cable chain selection even 7056.

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR5e is a lightweight industrial collaborative robot built for medium-duty applications (up to 5 kg). This general purpose robot was built with versatility and adaptability in mind. The UR5e is designed for seamless integration into a wide range of applications. Built with the future in mind, the UR5e is designed to grow in capability alongside your business, a spring board to improved product quality and productivity, so you will always be able to stay ahead of competition. Equipped with intuitive programming, versatile use and an almost endless list of opportunities for add-ons, the UR5e is able to complement production regardless of your industry, company size or product nature. The UR5e strikes the perfect balance between size and power.

Request for a quote

SAMEC S.R.L.

Italy

The End-of-Arm Tooling system for Sheet Metal handling named Octopus Grip consists in an octogonal-shaped central arm, attached to the wrist of the Robot Grips, specifically studied to be highly resistant to deflections/vibrations, with holes for the internal passage of air, and two or four patented quick ball coupling systems. The quick ball coupling systems allow the reconfiguration of the Robot Grips by simply changing their end effectors, in this case the tentacles of the Octopus Grip, that can be easily unhooked and placed close to the Robot Grips by a single operator on a vertical warehouse, allowing for savings in time required for changing the tools, and in storage space. The Octopus Grip system is highly flexible, from which it derives its name.

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR3e is an ultra-lightweight, compact collaborative industrial robot, ideal for table-top applications. Its small footprint makes it ideal to be built directly inside machinery or in other tight workspaces. This cobot weighs only 24.3 lbs (11 kg), but has a payload of 6.6 lbs (3 kg). Its ±360-degree rotation on all wrist joints, and infinite rotation on the end joint, makes it well-suited for light assembly and screwdriving applications.

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

We increase production speed by eliminating waiting times that reduce productivity in machine loading and unloading processes that do not require a high level of expertise. In addition we eliminate HSSE risks such as press feeding.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

With the robot wrist unit cartesian systems for the first time have the same flexibility and degrees of freedom as articulated arm robots. Only much cheaper and with much less space requirement. Moreover, IAI's unique design makes the components light and compact. Can also be used for an orthogonal axis system with interpolation function. The innovative wrist unit has two joints: The tilting joint for swivelling has a working circle of ±100⁰ while the rotary joint can be rotated around ±360⁰. The two pulse motors accelerate these cylinders at speeds of between 750 ⁰/s and 1,200 ⁰/s.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

SCARA robots are often used for the fast removal and movement of workpieces, smaller assembly applications such as screwing in screws, and for the precise dosing of liquids, adhesives and sealants. IAI offers a wide range of models, from the low-cost entry model IXP to the latest IXA high-performance SCARA robot.

Request for a quote

ROBOTNIK

Spain

RB-KAIROS+ is a mobile manipulator designed for the plug&play integration of Universal Robots e-Series arms. Its software and hardware are fully prepared to mount the arm OEM DC e-series and thus turn the robotic arm into an autonomous mobile manipulator. This allows unlimited expansion of the cobot workspace and an excellent way to improve the productivity of any factory. It is extremely useful for industrial applications such as pick and place, part feeding, metrology, quality control, operations on large parts or packaging, cleaning, polishing, screwing, drilling, etc.In addition, RB-KAIROS+ has been designed to be a collaborative mobile manipulator able to work in industrial environments. Thanks to its safety laser scanners (optional), the robot can safely share the workspace with the operators. RB-KAIROS+ has a robust steel design and can carry up to 250 Kg. The mobile platform has omnidirectional kinematics based on 4 high-power drive wheels. RB-KAIROS+ is a UR+ certified.

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR16e delivers an impressive 16kg (35.3 lbs.) of payload within a small footprint, and is ideal for use in heavy machine tending, material handling, packaging, and screw and nut driving applications. This powerhouse robot allows for heavier end of arm tooling and multi-part handling, and is especially useful for achieving shorter cycle times. The UR16e collaborative industrial robot is easy to program, offers fast set-up, is collaborative and safe, and like our other collaborative robots, offers one of the fastest payback times in the industry.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Suitable robots for almost every requirement What started with the first "intelligent" actuators at IAI today includes a wide range of industrial robots for all automation technology. The range includes cartesian robot systems, tabletop robots and SCARA robots. Matching controller with all common fieldbus connections complete the offer.

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The three axis of motion enable a high performance and an efficient design of the robot system. The central pick up table picks up a whole layer of glass from the pallet. The table pushes the layer on the discharge table in one operation which seperates the glasses and transfers them to the production line. Since the roTeg depalletizing robot DERO II works with clamping jaws, numerous package sizes can be processed without mechanical devices. In each depalletizing cycle the interlayers are also picked up by the glass layer and collected in a magazine. The movability of the robot construction on the x axis enables the handling of different production lines. While one discharge table is still filled with glasses and being emtied line by line the DERO II already takes the next layer and serves the second discharge table.

Request for a quoteResults for

Electronic industrial robotics - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Industrial robots (21)

- Assembly robots (14)

- Robotics (10)

- Automation - systems and equipment (7)

- Milling - steels and metals (4)

- Welding robots (4)

- Precision mechanics (3)

- Aerospace and aeronautics - construction (1)

- Bearings - ball, needle and roller (1)

- Construction - Machines & Equipment (1)

- Electric motors - dC (1)

- Machine tools, metal machining - parts and accessories (1)

- Milling and turning of rubber and plastic (1)

- Printed circuits (1)

- Rolling mills - machinery and installations (1)

- Software, technical and scientific (1)

- Welding, electric - equipment and supplies (1)