- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electromagnetic fields

Results for

Electromagnetic fields - Import export

HANS TURCK GMBH & CO. KG

Germany

Inductive sensors detect metal objects contactless and wear-free. For this, they use a high-frequency electromagnetic AC field that interacts with the target. Their strengths are the enormous durability, reliability, high switching frequencies and a long service life. Through a unique coil concept the uprox® sensors offer the highest switching distance, factor 1 for all metals and, right from the start, the highest operational safety through simple and safe installation.

Request for a quote

EMBRO GMBH

Germany

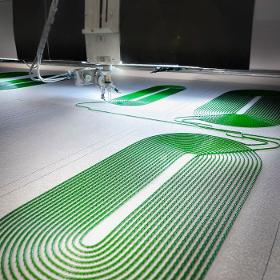

Where are magnetic field mats used? The coils currently manufactured by us are processed by our customers into so-called electromagnetic field mats. These mats are used in Pulsed Electromagnetic Field (PEMF) therapy. Many PEMF devices are suitable for private use at home. However, various health service providers including physical therapists as well as non-medical practitioners offer therapies based on magnetic fields. Why is our embroidery technology used for production? This technique creates circular-shaped structures that form the basis for a homogeneous flow/direction of the electric current. At the same time, the mechanical wire laying has an extremely high level of accuracy. The distances can also precisely be determined. How is the magnetic field created? Simply put, this is how electromagnetic fields are created: pulsating magnetic fields are generated by the electric current flowing through the wire. The more wire, the stronger the magnetic field.

Request for a quote

KELLER PRESSURE

Switzerland

The 22DT series has been specially developed for use in bivalent vehicles (volume flow measurement when running on natural gas) and is homologated for the automotive industry. However, it also has other industrial applications. The NTC or PT temperature sensor located directly beneath the steel diaphragm reacts more quickly to temperature changes thanks to its special design. The pressure transmitters are protected against electromagnetic fields up to 200 V/m and output the measured values as a ratiometric 0,5...4,5V analog signal. The connections of the temperature sensor are fed out directly.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to its high resolution also when measuring long distances, linear displacement measurements up to 900 mm can be carried out. Conversions between rotatory and translation movements through ball screws, wire or cord connections and so on are not necessary for direct displacement measurement. Application fields include: —Electromagnets —Deformations - bending —Pneumatic cylinders —Length tolerances —Press-insertions (longitudinal press-fits) —Feed strokes —Machine hubs —Punch, knee lever or extruder distances —Hydraulic cylinders Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. Special processes are applied to give the resistance tracks low friction, low tendency to stick/slip, resistance to abrasion and long-term stability. The rod is guided in a low-play floating frontal bearing. This absorbs small angular and parallel displacements.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

AXON CABLE SAS

France

SpaceWire link is used to enable the reliable transmission of data at high speed (between 2 Mb/s and 400 Mb/s) from one unit to another. SpaceWire links are full-duplex, point-to-point, serial data communication links. Advantages Near constant total drive current (+3,5 mA for logic 1 and -3,5 mA for logic 0) which decreases switching noise on power supplies. High immunity to ground potential difference between driver and receiver. LVDS can tolerate at least ±1 V ground difference. High immunity to induced noise because of differential signalling normally using twisted-pair cable. Low EMI because small equal and opposite currents create small electromagnetic fields which tend to cancel one another out. Not dependent upon particular device supply voltages. Simple 100 Ohms termination at receiver. Power consumption is typically 50 mW per driver receiver pair for LVDS compared to 120 mW for ECL or PECL.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The main characteristic of the magnetic particle clutch is the possibility to smoothly change the torque depending on the field voltage. To transmit the torque from the external to the internal rotor, specifically alloyed and highly abrasion-resistant iron particles are inserted into the particle gap. Depending on the electromagnetic field, these fine iron particles build magnetic chains and thus transmit the torque. The power of the field determines the stability of the particle chains and also the transmittable torque.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Active Clutch Line includes DC slip-ring-free single-disc clutches, in which the action of force of an electromagnetic field (electromagnetically closing) is used to transmit the torque. The clutches of the Active Clutch Line are characterized by a secure, residual moment-free lifting in any position and by a backlash-free transfer of the torque. Throughout their complete service life, they require little or no maintenance. Depending on the clutch version, higher switching capacities can be achieved.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The High Torque series combines the well-known properties of permanent magnet brakes - Due to a re-design of the magnetic circuit, it features further advantages such as a higher torque at identical size and power consumption, high torque constancy throughout the complete service life and an extended temperature range. The High Torque brake is designed to operate dry. The force generated by a permanent magnetic field is utilised to produce the braking effect. To neutralise the braking action, the magnetic flux of the permanent magnets is cancelled by an alternate electromagnetic field (electromagnetically released system). The zero backlash connection between the armature and flange hub ensures zero backlash transmission of the brake torque to the machine shaft (e.g. motor shaft) and reliable release of the High Torque brake with zero residual torque. Thanks to these features, High Torque brakes are ideal for servo motor applications.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Active Brake Line includes DC single-disc brakes, in which the action of force of an electromagnetic field (electromagnetically closing) is used to generate the braking force. The Active Brake Line is characterized by a secure, residual moment-free lifting in any position, and by a backlash-free transfer of the braking torque. Throughout their complete service life, they require little or no maintenance.

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

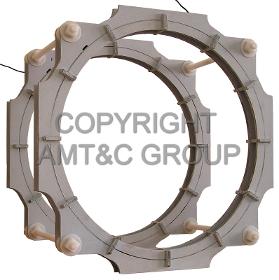

Electromagnetic system with a high field uniformity in the working volume ~ 1 cm3. It can be used for calibration of different types of magnetometers. Low power consumption allows continuous operation without cooling in the field range of ± 50 mT. The system can be controlled by a computer. Basic technical parameters: - overall dimensions - 280 × 340 × 340 mm; - net weight - ~ 95 kg; - maximal magnetic field induction - 50 mT; - the field inhomogeneity in the operating region - 0.01 - 0.05 %; - power consumption - ~ 200 W; - PC control mode, including the polarity reversal, is available.

Request for a quote

IDEMAG

Spain

The electromagnetic separators suspended on conveyor belts are the most effective equipment for removal of ferrous contamination from other nonferrous materials. Consist of an electromagnet which creates powerful magnetic fields that are generated by electrical coils which provide the required attractive force to separate the iron pieces. The self-cleaning of the equipment is performed by a resistant rubber belt and provided with transverse projections.This facilitates the transport of material and separation of the captured contamination throwing it to one side of the conveyor. The belt is mounted on a metal frame with pulleys that rotate with its bearings and is driven by an electric motor with a speed reducer; belt tensioning is done through a deflection drum. Its main mission is the protection of crushing and grinding equipment against damage and wear caused by the presence of iron pieces.The electromagnetic overbands separate ferrous particles from other materials in recycling pr.

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

For reducing losses, in high-frequency or pulse-field applications, electromagnetic coils can be designed using dielectric materials for their frames. Also the winding can be made of multi-strand high-frequency cable.

Request for a quote

IDEMAG

Spain

The electromagnetic separators suspended on conveyor belts, are the most effective equipment for removal of ferrous contamination from other nonferrous materials. Consist of an electromagnet which creates powerful magnetic fields that are generated by electrical coils which provide the required attractive force to separate the iron pieces. Those pieces are attracted towards the poles remaining there until they are manually cleaned. The cleaning is performed by the demagnetization of the equipment, so all ferrous contaminants will come off. Its main mission is the protection of crushing and grinding equipment against damage and wear caused by the presence of iron pieces. The electromagnetic plates separate ferrous particles from other materials in the recycling processes. Lower production costs by avoiding repairs to the crushing equipment. At the same time this magnetic system increases productivity by avoiding downtime repair periods and raises the value of the materials

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

The compact system of permanent magnets NdFeB, designed according to the principle of the dipole Halbachstructure, allows to get, inside the bore, rather homogeneous magnetic field with the magnetic flux density up to 23 Tesla. The system can be an efficient alternative to electromagnetic sources of the magnetic field, and can be used in scientific and applied research requiring magnetic fields of high intensity. Geometrical dimensions and magnetic flux density in Halbachtype systems can vary widely, the attached data and photos are typical examples. AMT&C LLC offers the manufacturing of steady magnetic field systems according the customer technical specifications. To improve the temperature stability the system can be assembled of SmCo magnets.

Request for a quote

MICROCYBER

China

Fieldbus power conditioner applies to Foundation Fieldbus and PROFIBUS PA control system and provides power to bus-powered devices. Matched with Fieldbus terminator, it adopts uniform impedance characteristic to reproduce bus signal perfectly. NCS-BP105 Fieldbus Power Conditioner: NCS-BT105 Fieldbus Terminator: 1. Bus power supply, suitable for fieldbus conforming to IEC 61158-2 standard 2. Comply with the FF-831 bus power supply test specification 3. Support power supply redundant connection 4. Active impedance control method 5. Servo voltage output, meeting the requirements of long distance power supply

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALFA-MED LLC

Russia

The work of the TempoHeart module is based on the method of scoring the heart rate vegetative regulation. This method is popular due to its high information value and non-invasiveness. Cannot be used without an interface block. The module can: • evaluate the heart rate autonomic regulation; • to predict in advance (to prematurely reveal) the hazards of a myocardial infarction, hypertensive crises and strokes; • to determine the metabolic and electrolyte disorders in the myocardium; • identify risk groups for heart rate increased stability; • to make a cold evaluation of the autonomic nervous system's reaction when exposed to electromagnetic fields, intoxications and other pathogenic factors; • to assess the activity of the respiratory component when measuring heart rate variability, recording the parameters of blood movement in the vessels; • to expose the stress resistance level.

Request for a quote

FELEMAMG,S.L

Spain

DESCRIPTION Self-cleaning electromagnetic overband separators are designed for extraction and retrieval of ferrous magnetic materials from conveyed material. The overband separator is made of a powerful electromagnet, which supports the small ribbed belt covering the electromagnet. Small frames interlocked to the electromagnet support the drive drum, redelivery drums, and gear motor driving the band. Self-cleaning electromagnetic overband separators are used for automatic extraction of materials, ensuring high recovery of ferrous materials. PRINCIPLE OF OPERATION As the ferrous magnetic materials on the conveyor belt come within the electromagnet’s magnetic field, the ferrous material is attracted and pulled up to belt around the magnet. Ribs clear ferrous materials of the electromagnet’s magnetic field and discharge them freely. Separators may be cross-mounted across the conveyor belt or at the head of the conveyor.

Request for a quoteResults for

Electromagnetic fields - Import exportNumber of results

20 ProductsCompany type

Category

- Brakes, servo-brakes and accessories (3)

- Electromagnets (3)

- Magnetic equipment (3)

- Biogas and biofuel - energy use (1)

- Clutches (1)

- Electric cables (1)

- Extraction machinery and equipment - minerals and ores (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Medical Equipment (1)

- Medical electronics - apparatus and equipment (1)

- Natural fertilizers (1)

- Package stamping machinery (1)

- Packing and packaging - machinery and equipment (1)

- Precision measuring instruments (1)

- Sensors (1)